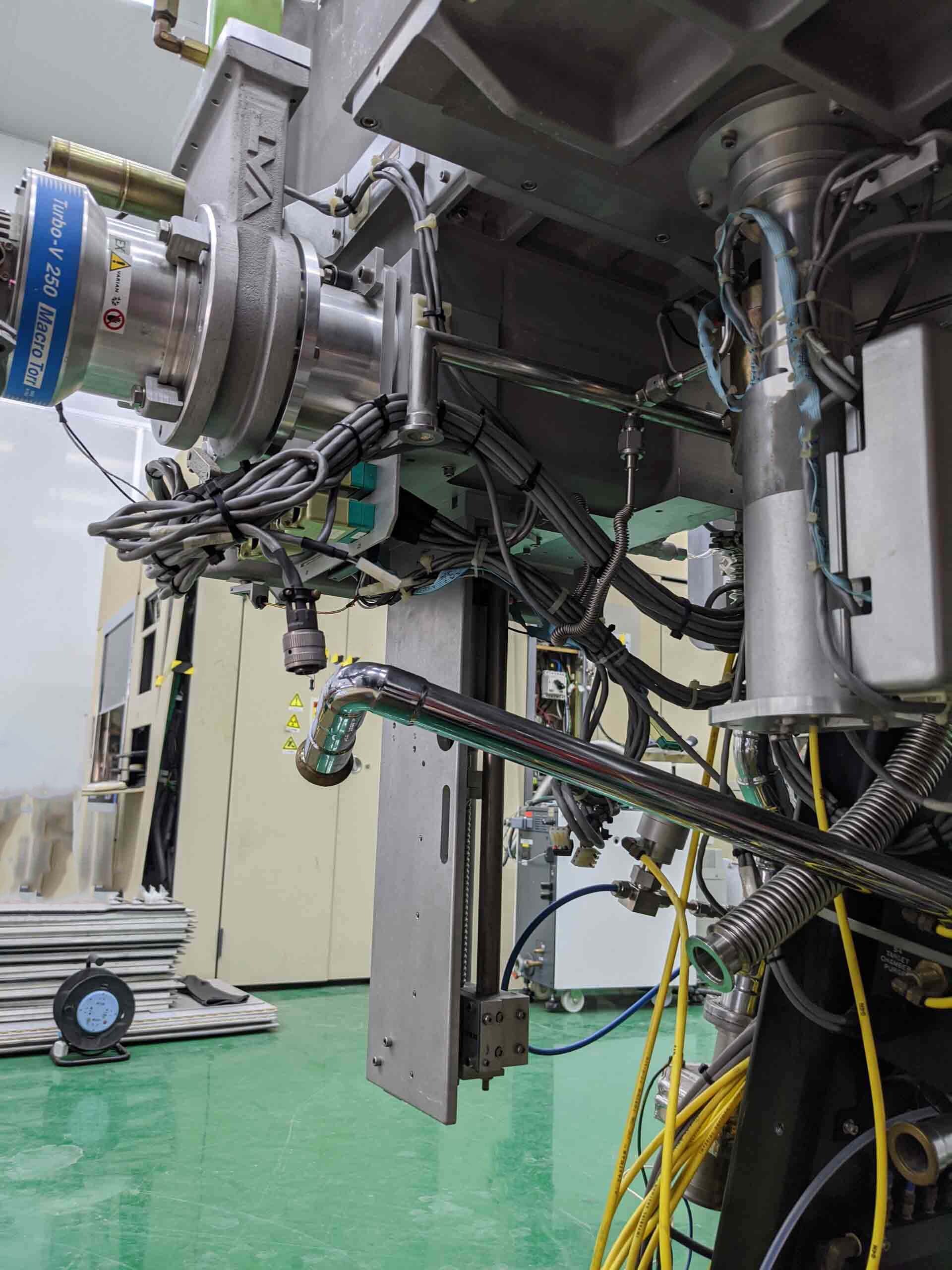

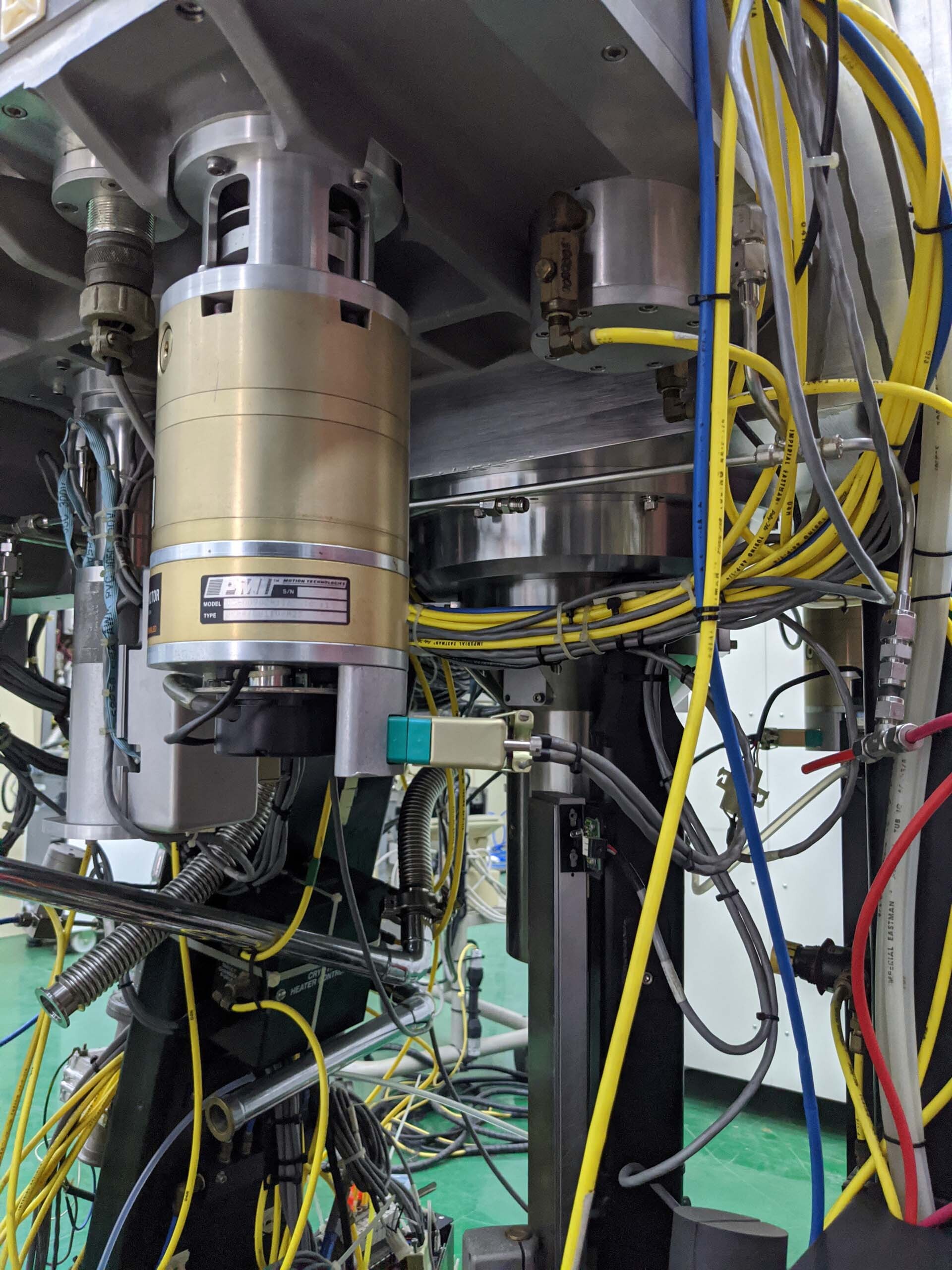

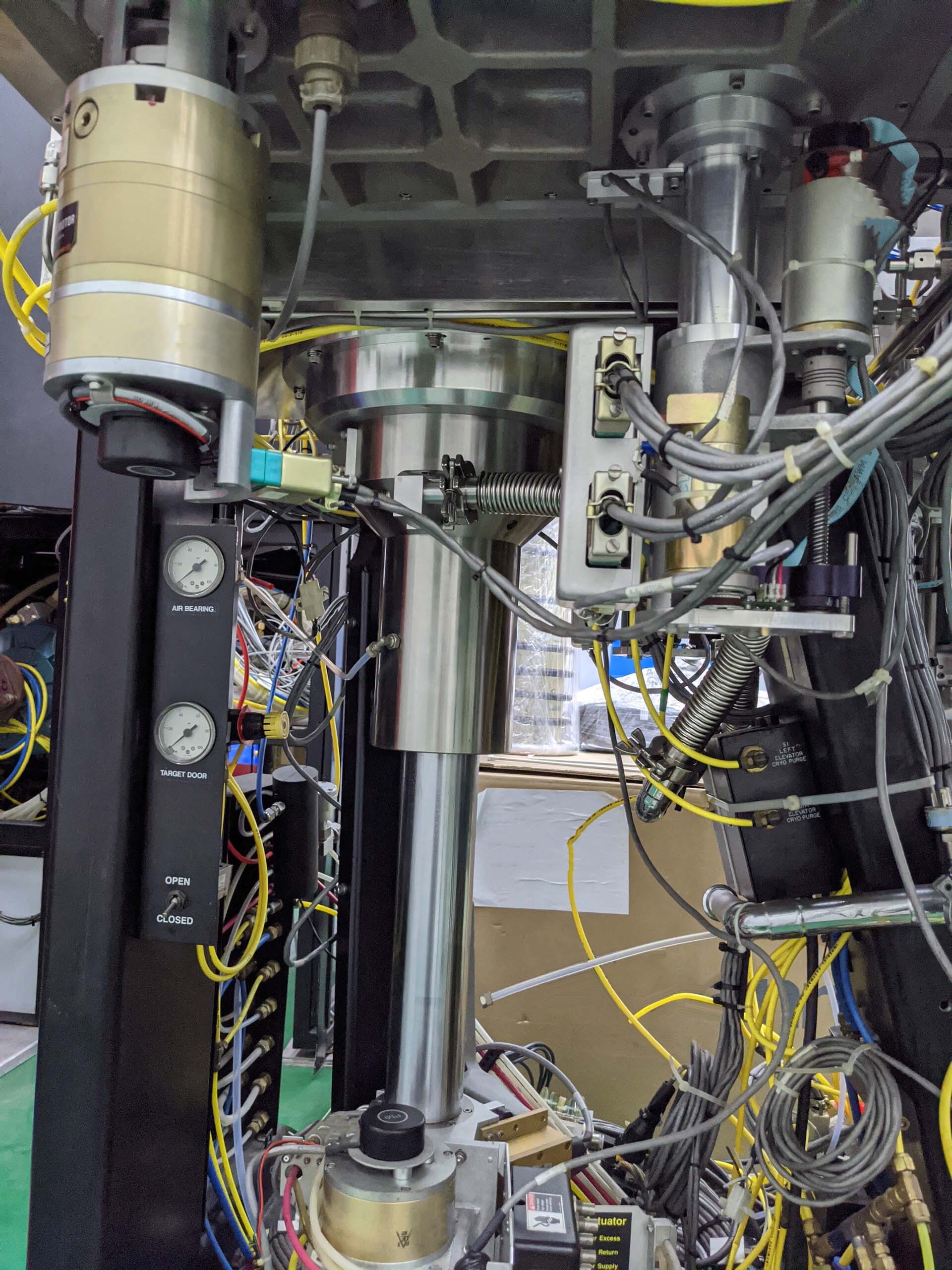

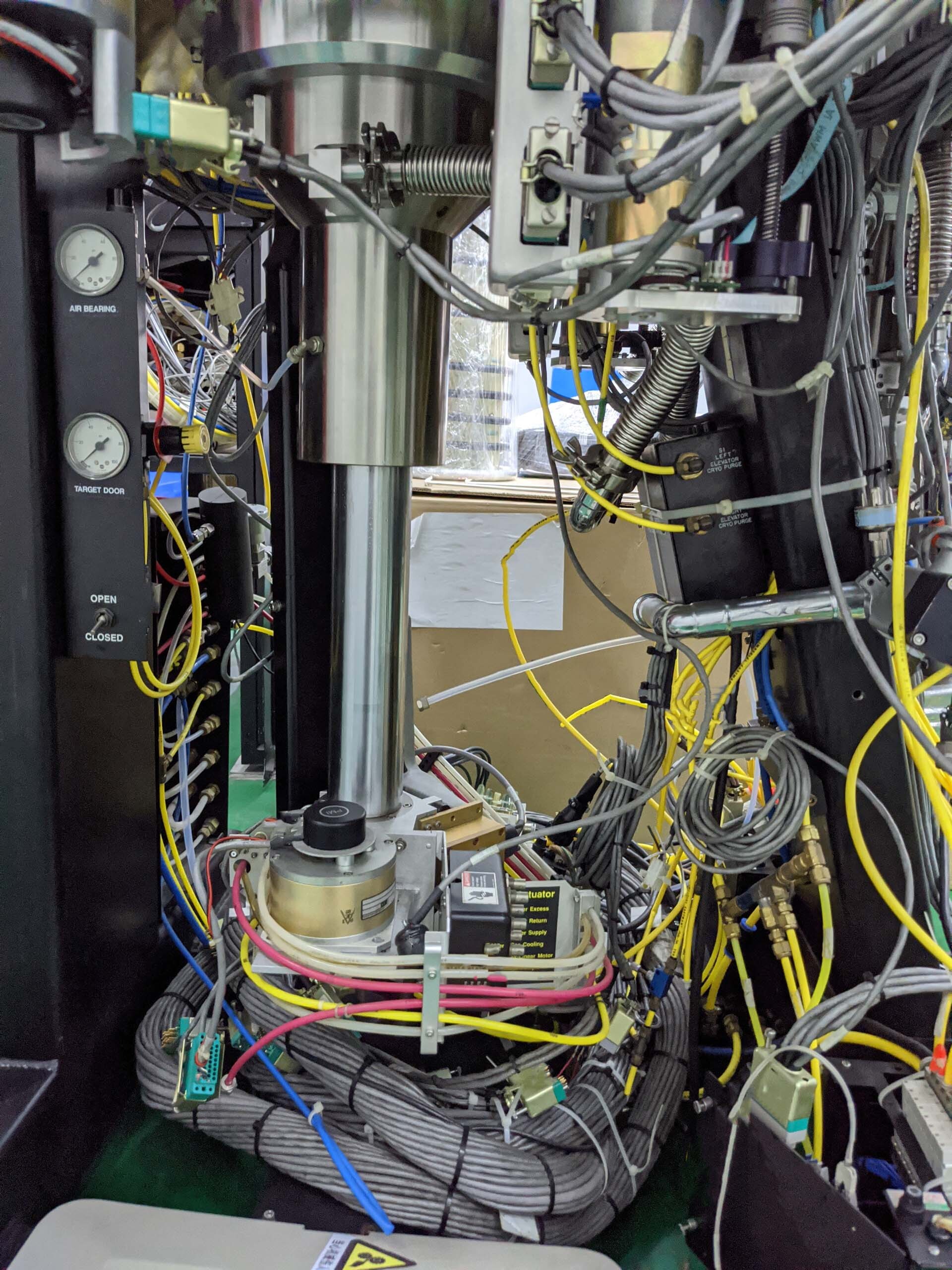

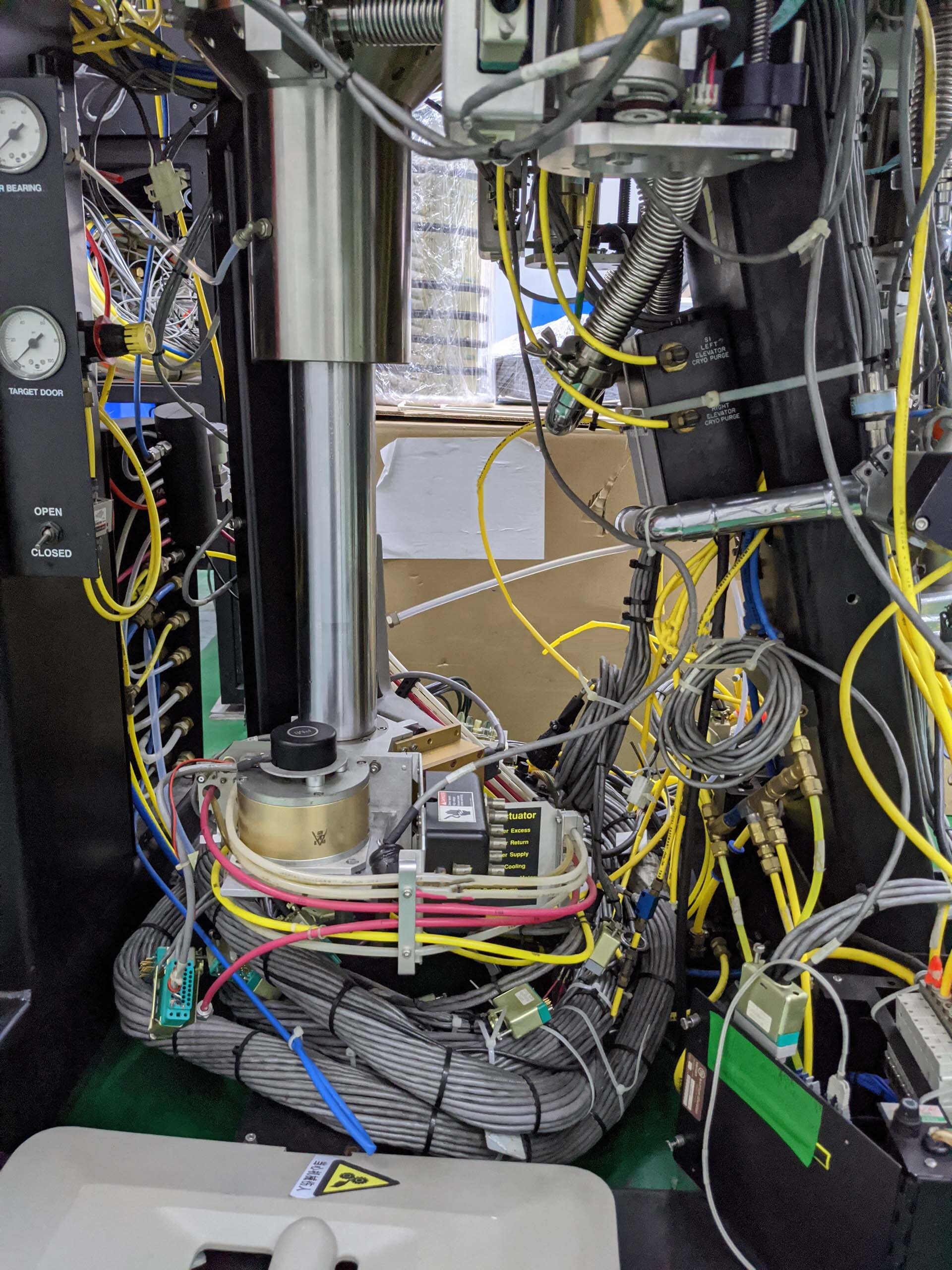

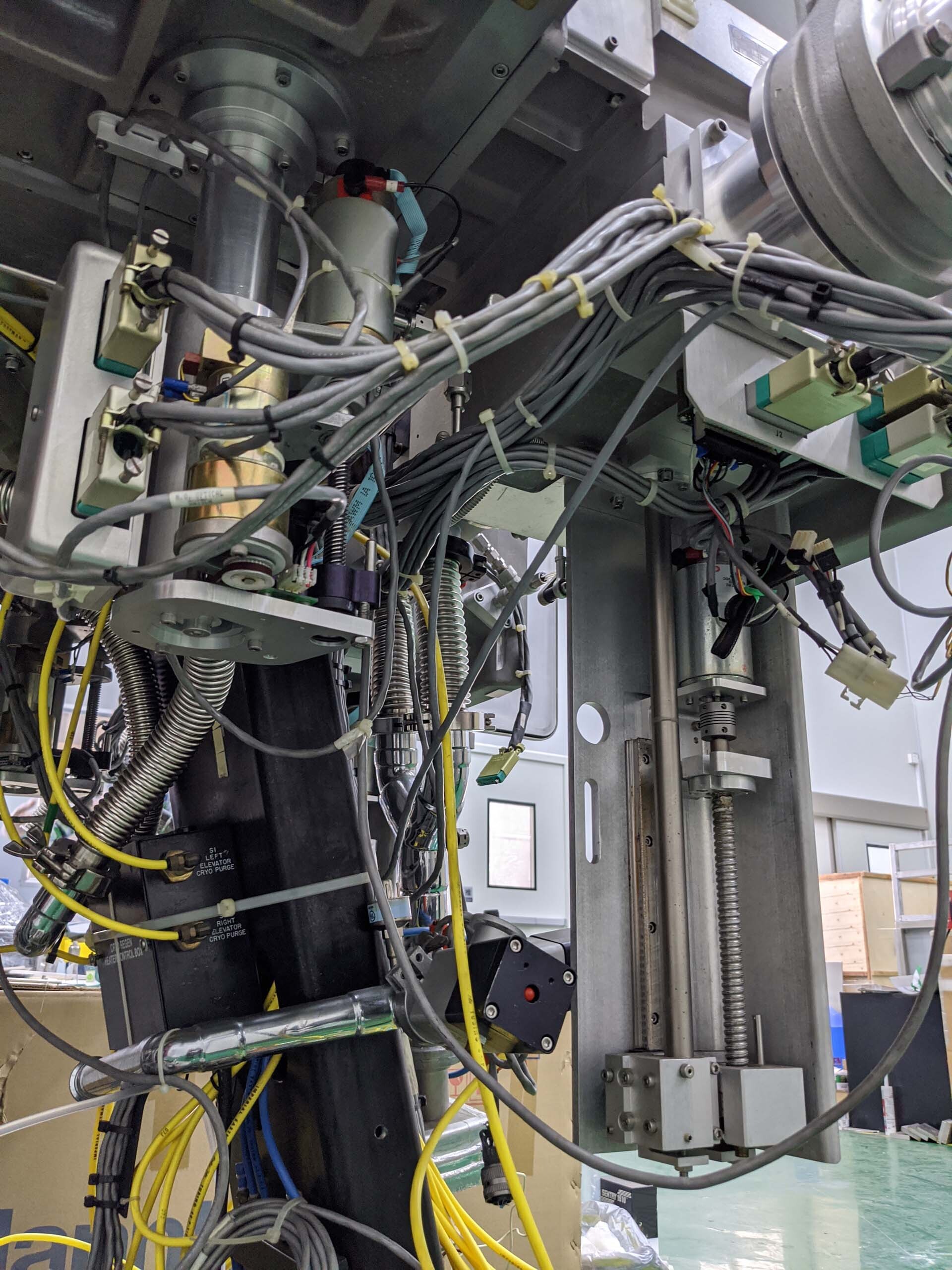

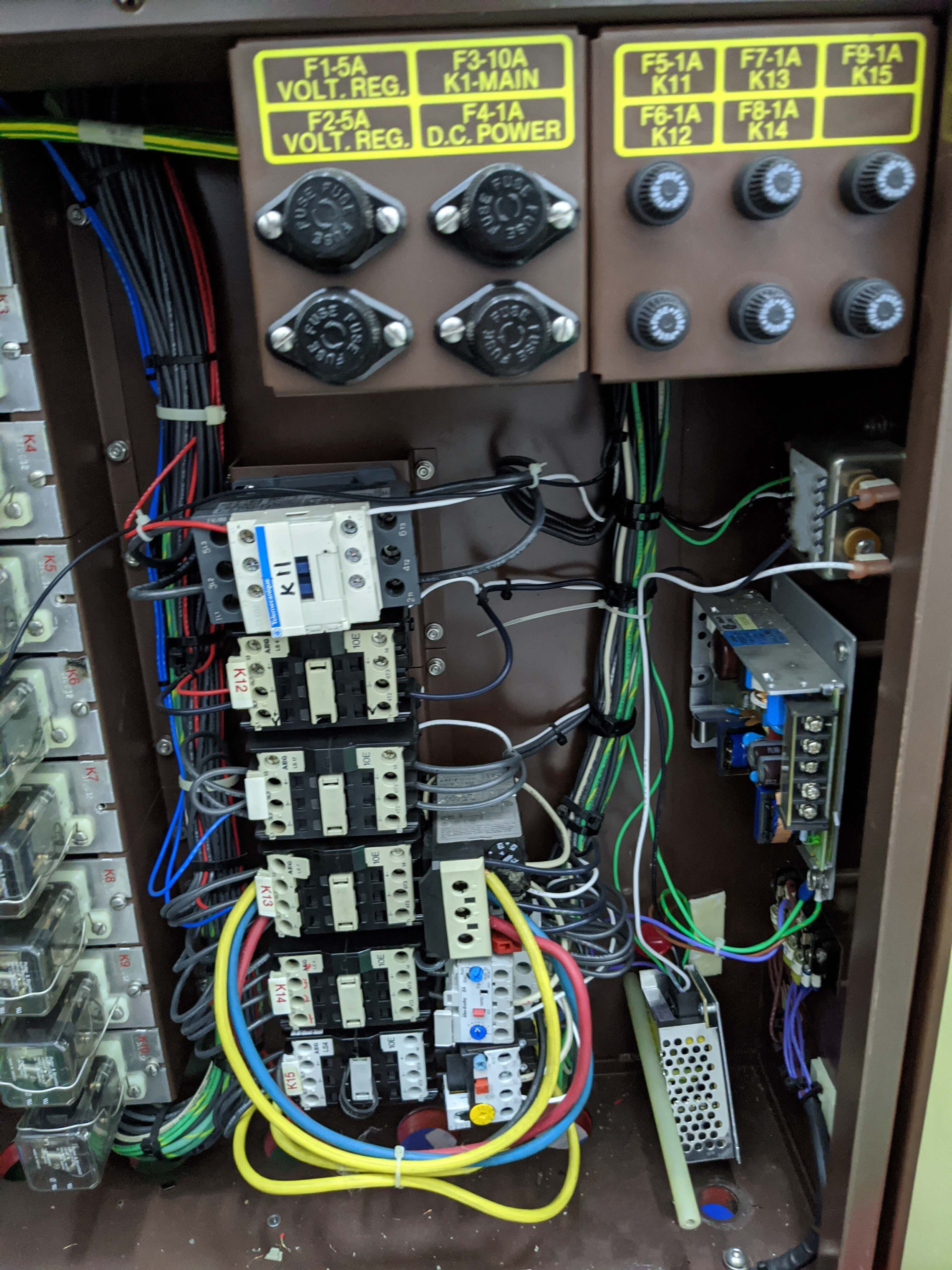

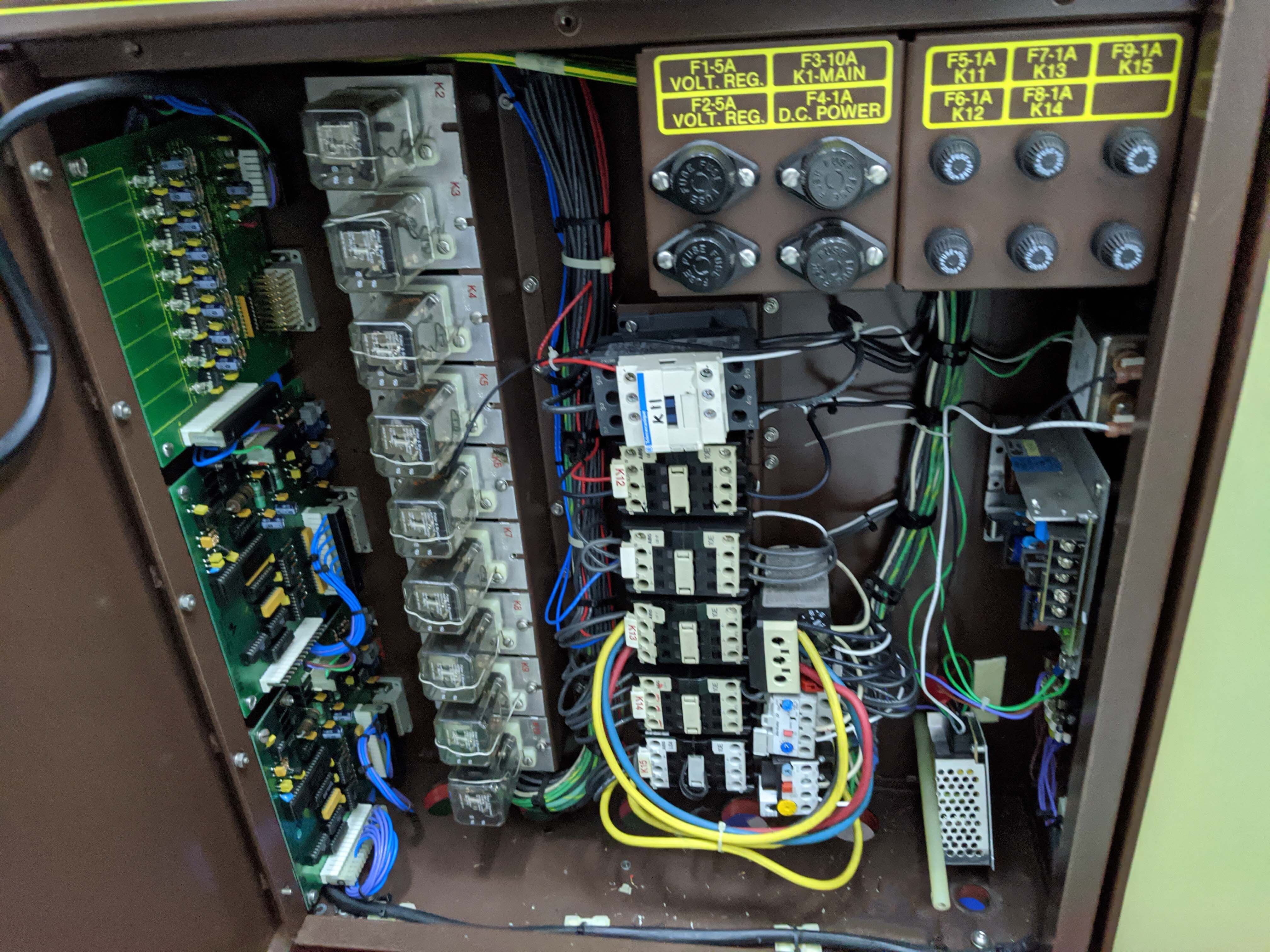

Used VARIAN E220 #9361402 for sale

URL successfully copied!

Tap to zoom

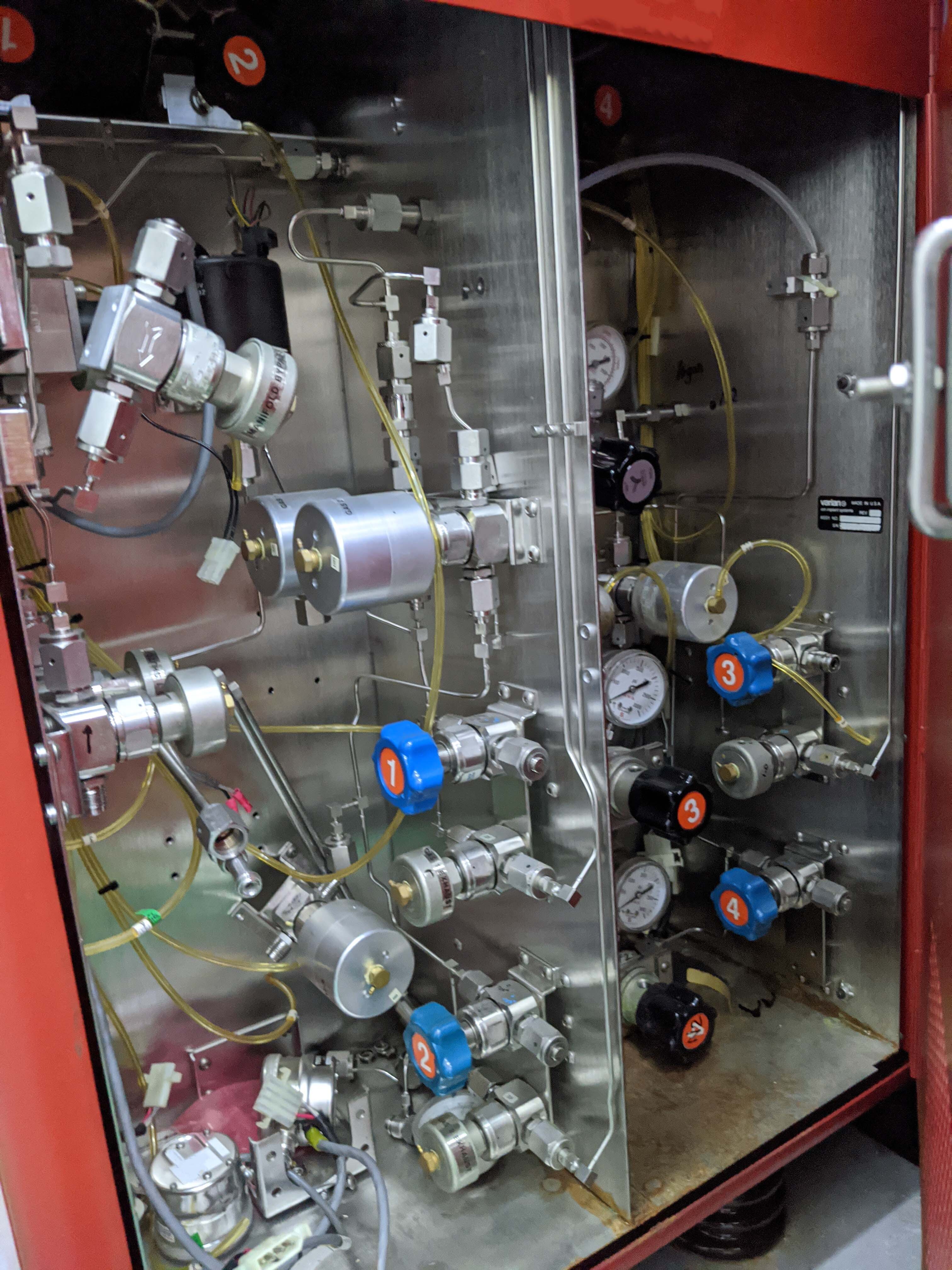

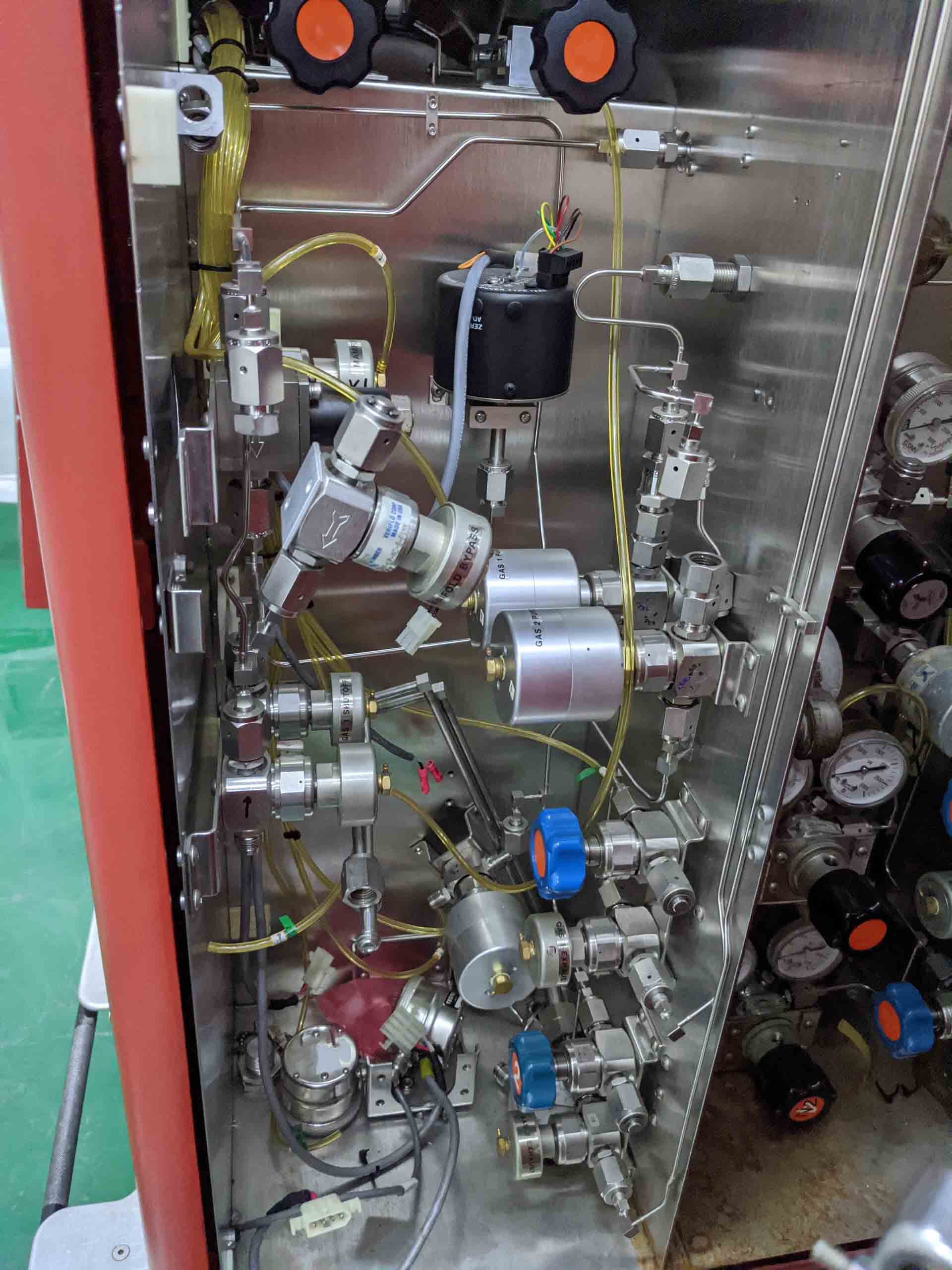

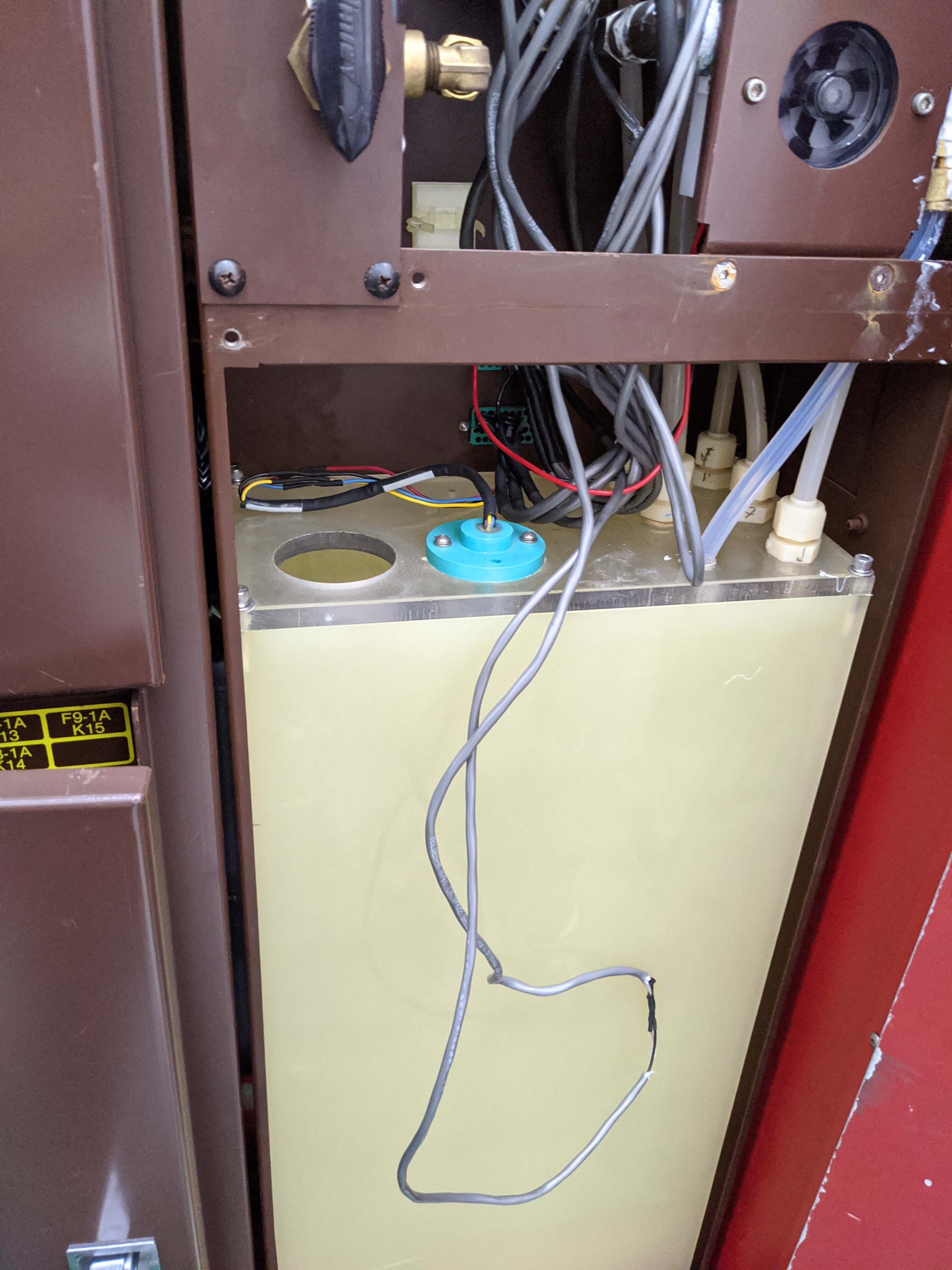

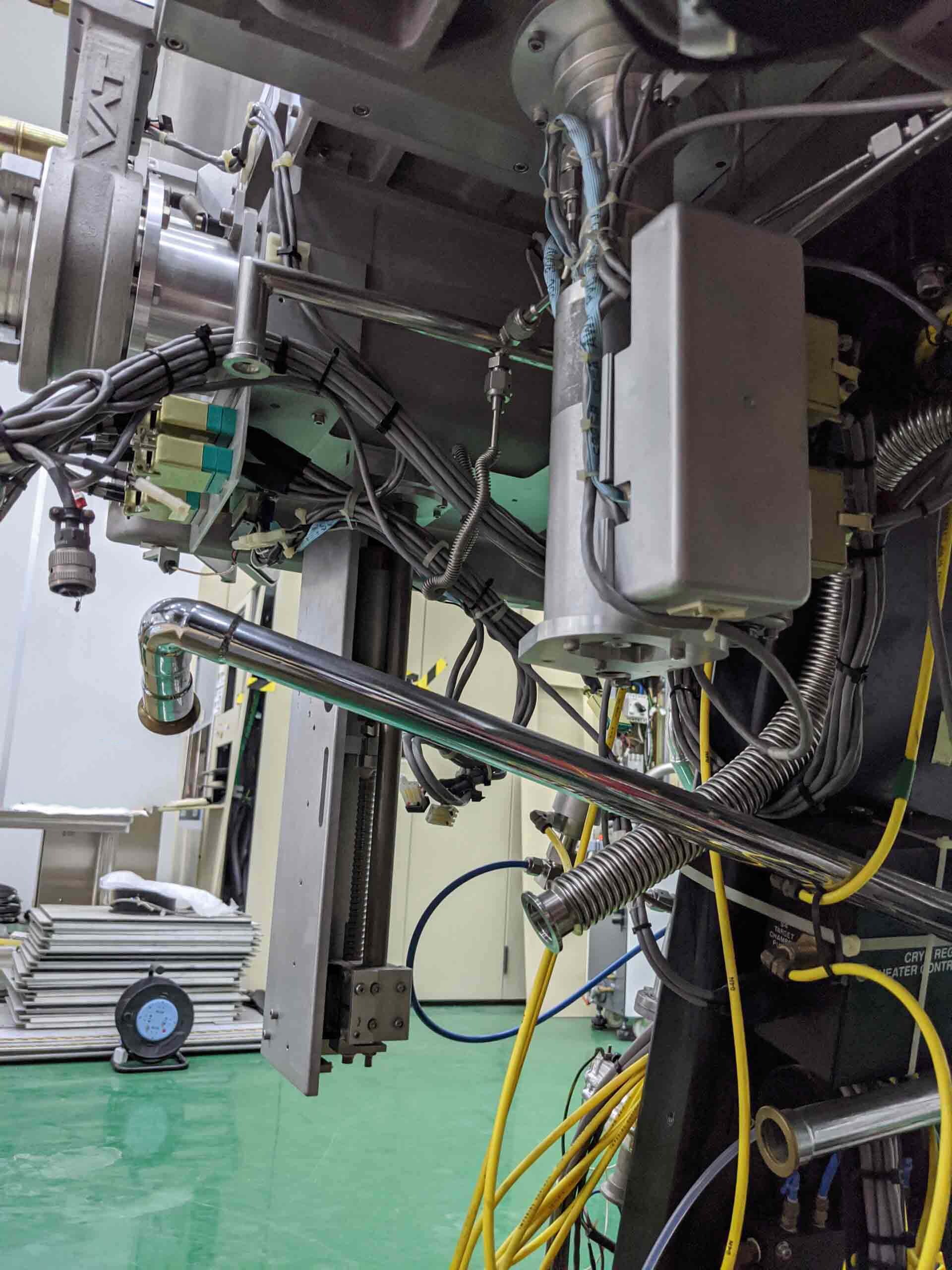

ID: 9361402

Wafer Size: 6"

Medium current ion implanter, 6"

Signal tower: Front panel

Single wafer

E-Chuck

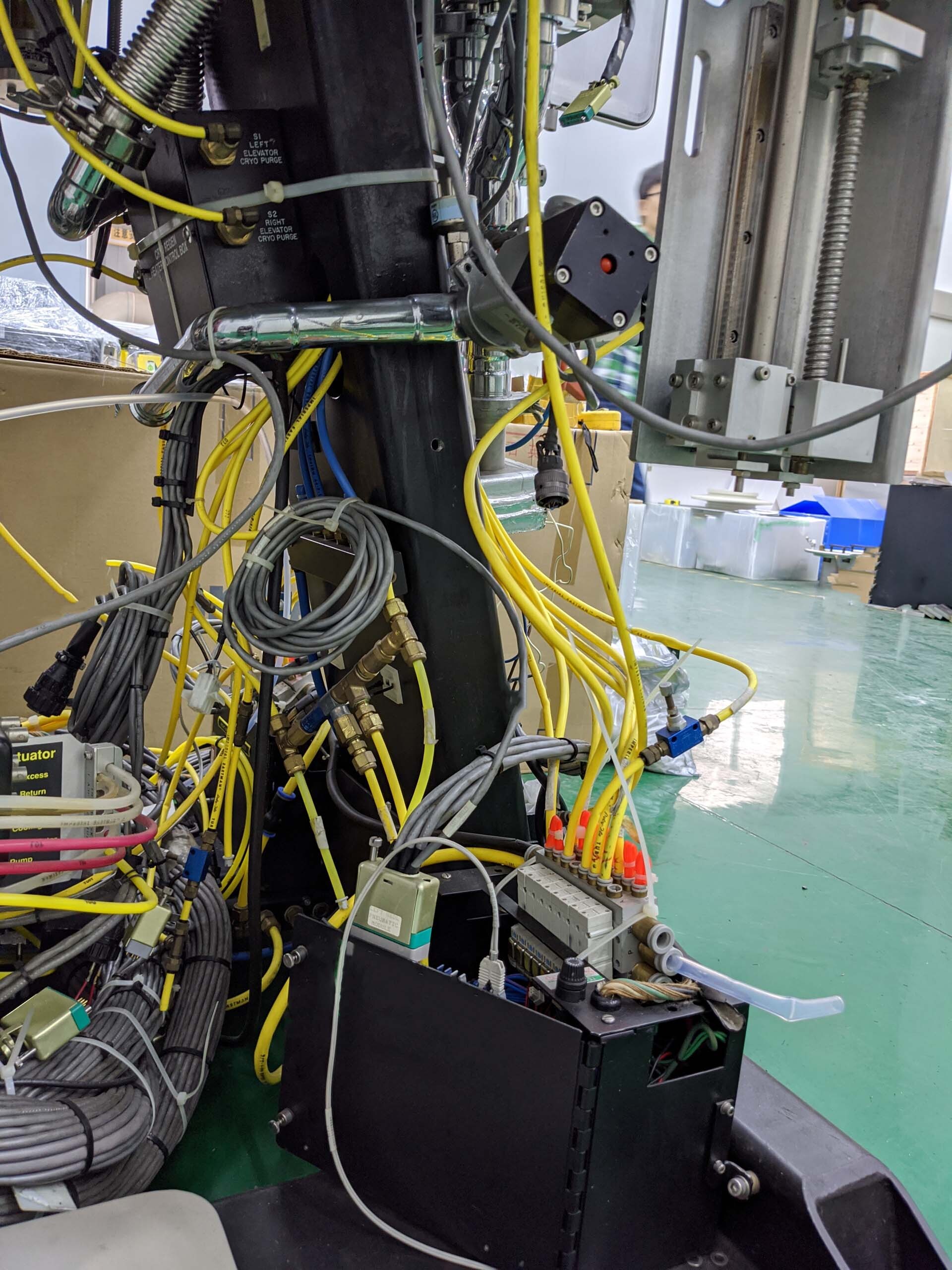

Loadlock: Left / Right

VAT Gate valve missing

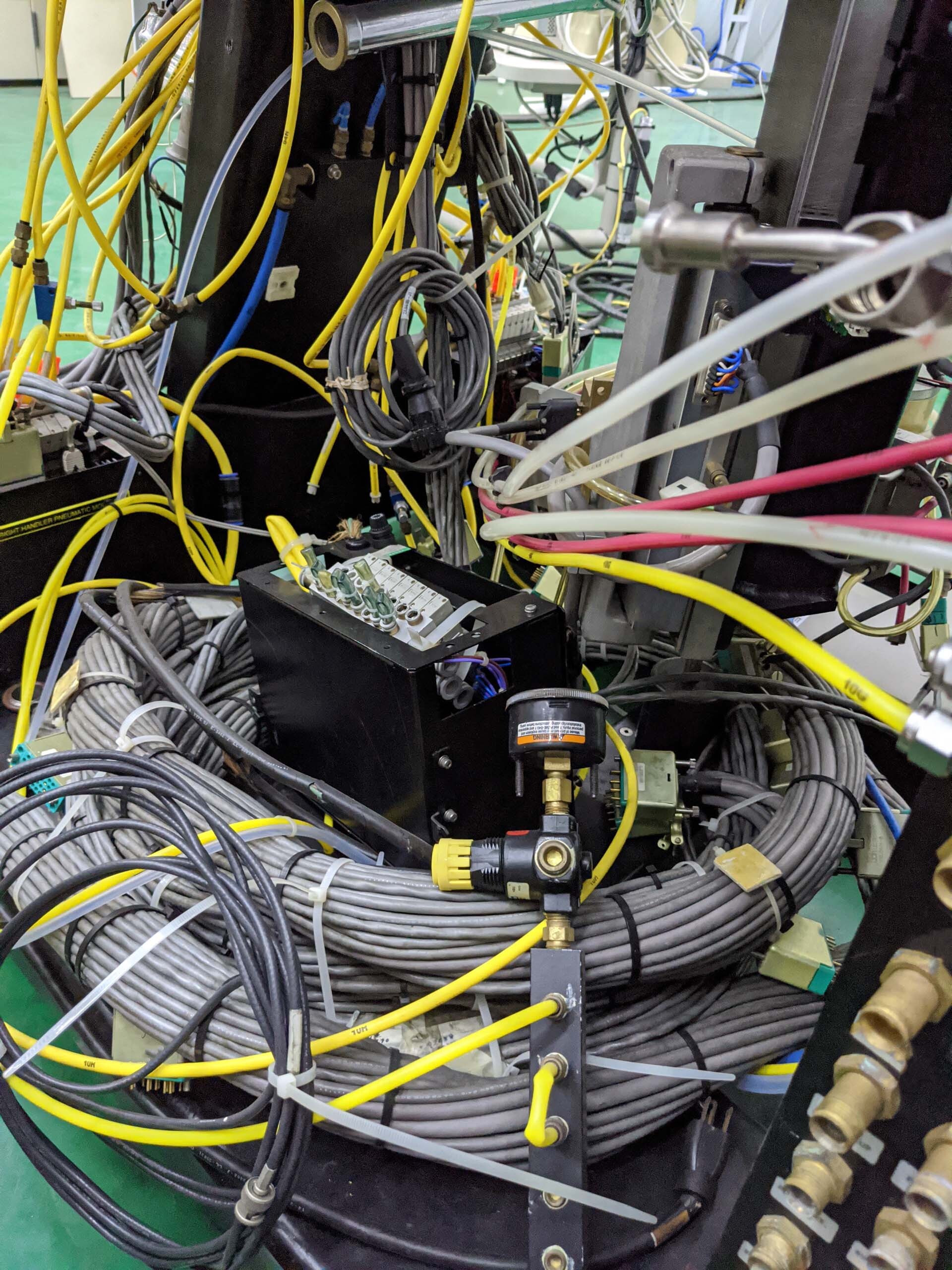

Vacuum:

Ion source chamber

Beam line chamber

End station chamber

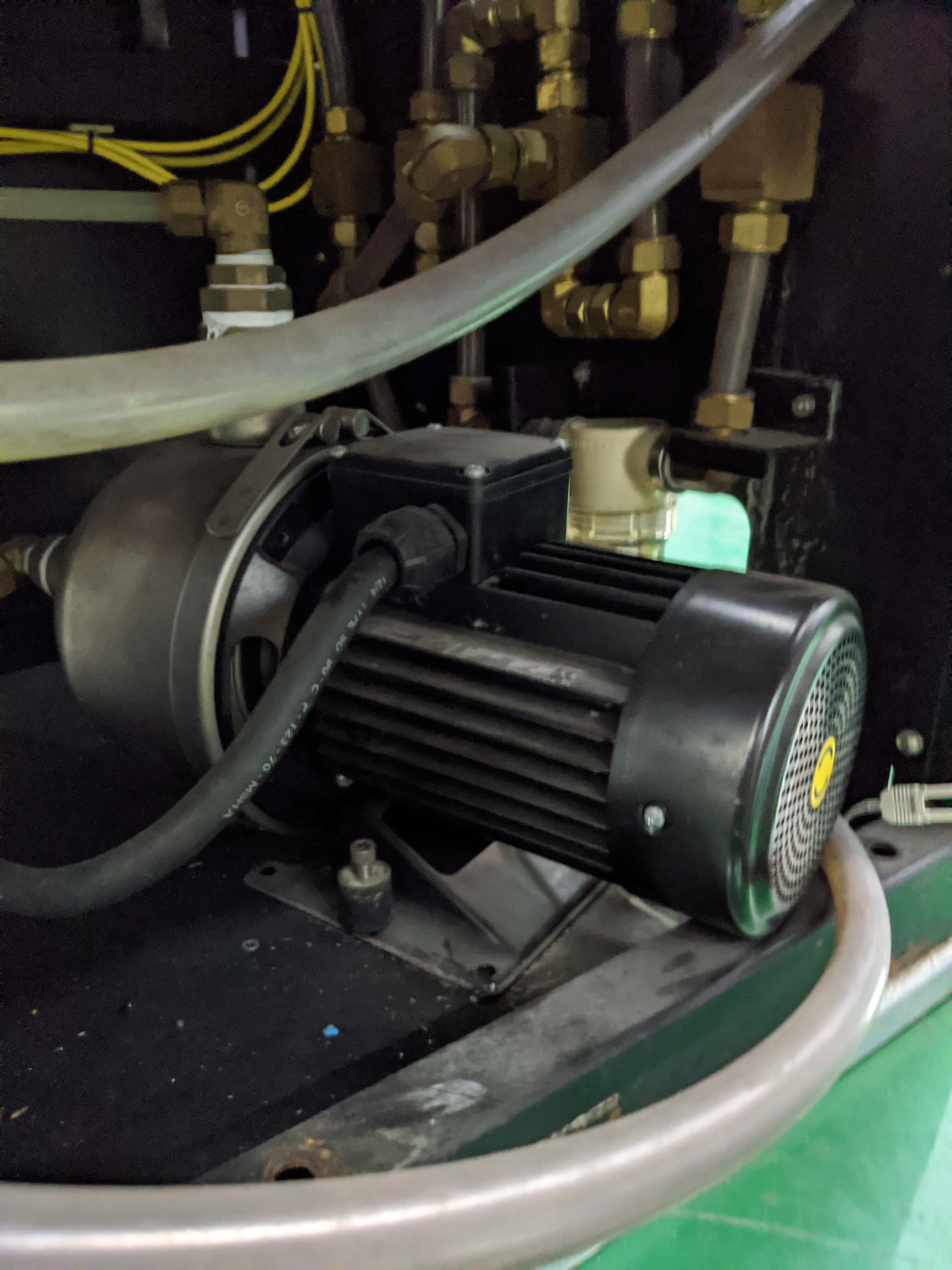

Pumps:

Terminal:

Dry pump

Turbo pump

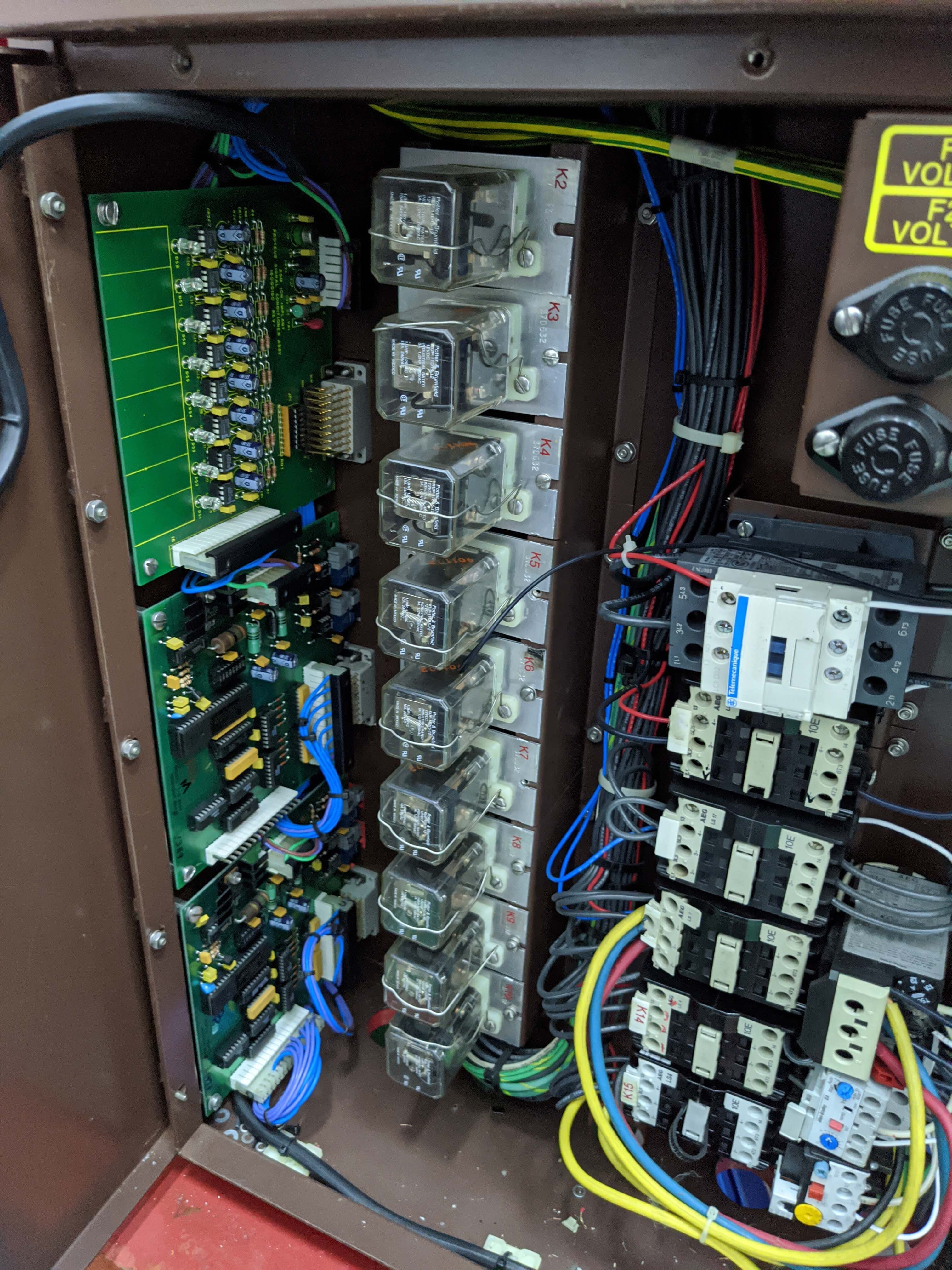

(3) Controllers

E/S Chamber:

Dry pump

Dry pump / Booster pump

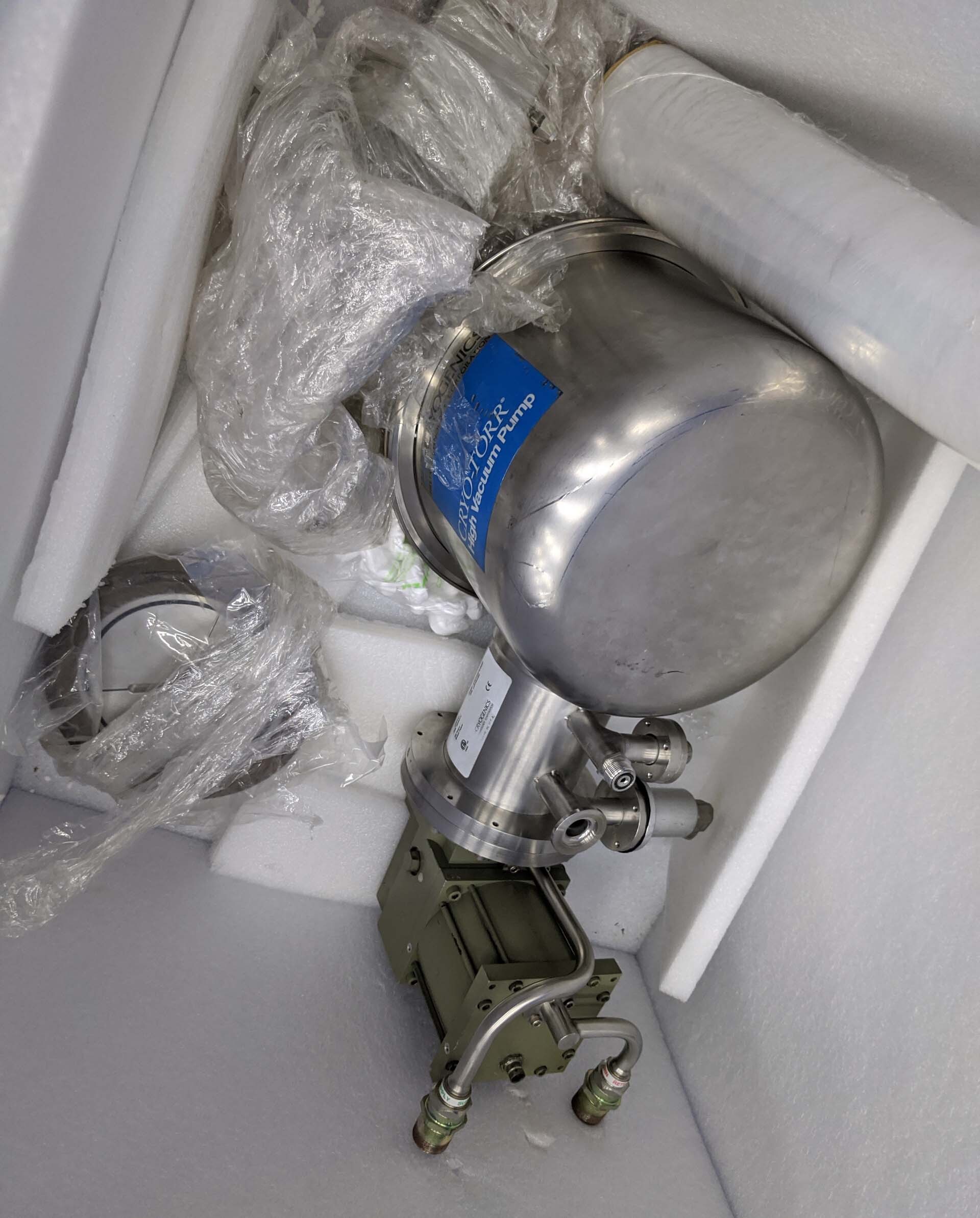

Cryo pump

L/L Turbo pump

Maker / Model / Class

EDWARDS / QDP80 / Terminal dry pump

PFEIFFER / TPH 1600 / Source TMP

PFEIFFER / TCP 5000 / Source TMPC

PFEIFFER / TPH 510 / Resol TMP

PFEIFFER / TCP 310 / Resol TMPC

PFEIFFER / TPH 240 / Beam line TMP

PFEIFFER / TCP 121 / Beam line TMPC

CTI / 250F / End station C/P

CTI / 9600 / Compressor

VARIAN / CTI100 / Loadlock TMP

VARIAN / CTI100 / Loadlock TMPC

EDWARDS / QMB250 + QDP40 / End station dry

Process gas:

Type / Gas / CGA Outlet

HP / AsH3 / CGA 577

HP / PH3 / CGA 578

HP / BF3 / CGA 579

HP / Ar (N2) / CGA 580

High voltage range:

Extraction power supply: 0 keV~40 keV

Acceleration power supply: 0 keV~180 keV

Power supplies (Assembly):

Filament

Vaporizer

Source magnet

Extraction

Extraction suppression

Analyzer magnet

Mirror power supply (Decel)

(2) Quadrupole magnets

Scan generator controller

Mirror

Dipole lens magnet

Acceleration

Acceleration suppression

Scan trek power supply

Isolation transformer assembly

Mirror read back assembly: 60 keV

Controller (Assembly):

Left arm servo

Right arm servo

Vacuum gauge

Scan faraday

Platen tilt servo

Vertical lift orienter

Uniformity

Liner motor servo amp

Orienter

Left and right elevator

Dose integrator

DI Temperature monitor

Options:

Beam reducer

Decel

Gas box type: HP

Source type: Bernas

Faraday type: VARIAN Scanning faraday

Utilities:

Air: 100~150 PSI

N2: 40~150 PSI

Cooling water: 60~150 PSI

Temperature: 4°C~21°C

Power supply: 208 VAC, 3-Phase, 5-wires, 43.2 kVA, 120 FLA.

VARIAN E220 is a powerful ion implanter and automated monitor designed for demanding ion implantation applications. Its easy-to-use features and systems allow for the accurate control of implantation process parameters, resulting in high quality and throughput of substrates. The equipment offers a wide variety of process settings and capabilities, including single or multi-ion, variable voltage, external beam setup, plasma sheets, and a range of other sophisticated features. Its sophisticated hardening tools are designed to implant dopants into the substrate in high concentrations, without damaging the substrate material. The system also offers a versatile implantation process, allowing it to handle a wide range of materials. It comes equipped with a built-in high-density sensor measuring ion current density and energy. The sensor can detect the ion density in the substrate to maintain the desired implantation rates. VARIAN E-220 has an efficient environmental control in order to ensure the ideal conditions for the substrate. Its advanced environmental control will reduce the amount of energy used during implantation and improve the accuracy of the results. The unit also features an ion source that is powered by a direct current, eliminating the need for forming gas and reducing the risk of contamination. The source contains a high-efficiency focusing machine which helps stabilize substrate temperature. Its sophisticated beam line control makes E 220 an ideal choice for a reliable implantation process. Specialty hardware, such as electrostatic deflectors and ion guides, provide precise control of the beam and ensure uniformity of the implantation. The automated beam line control will automatically adjust the beam size and shape as needed, resulting in precise and effective implantation of the desired ions. The tool comes with powerful software that makes the process user-friendly and convenient. Data logging, advanced diagnostics, and other monitoring features make it easier to track and analyze the progress of the implantation. The software also supports advanced statistical analysis and verifiable records. VARIAN E 220 is a versatile and reliable asset for advanced ion implantation needs. With its wide range of features and capabilities, it is well-suited to tackle demanding implantation requirements that involve a variety of materials. Its sophisticated hardware and software make it an ideal choice for achieving varied results at high precision levels.

There are no reviews yet