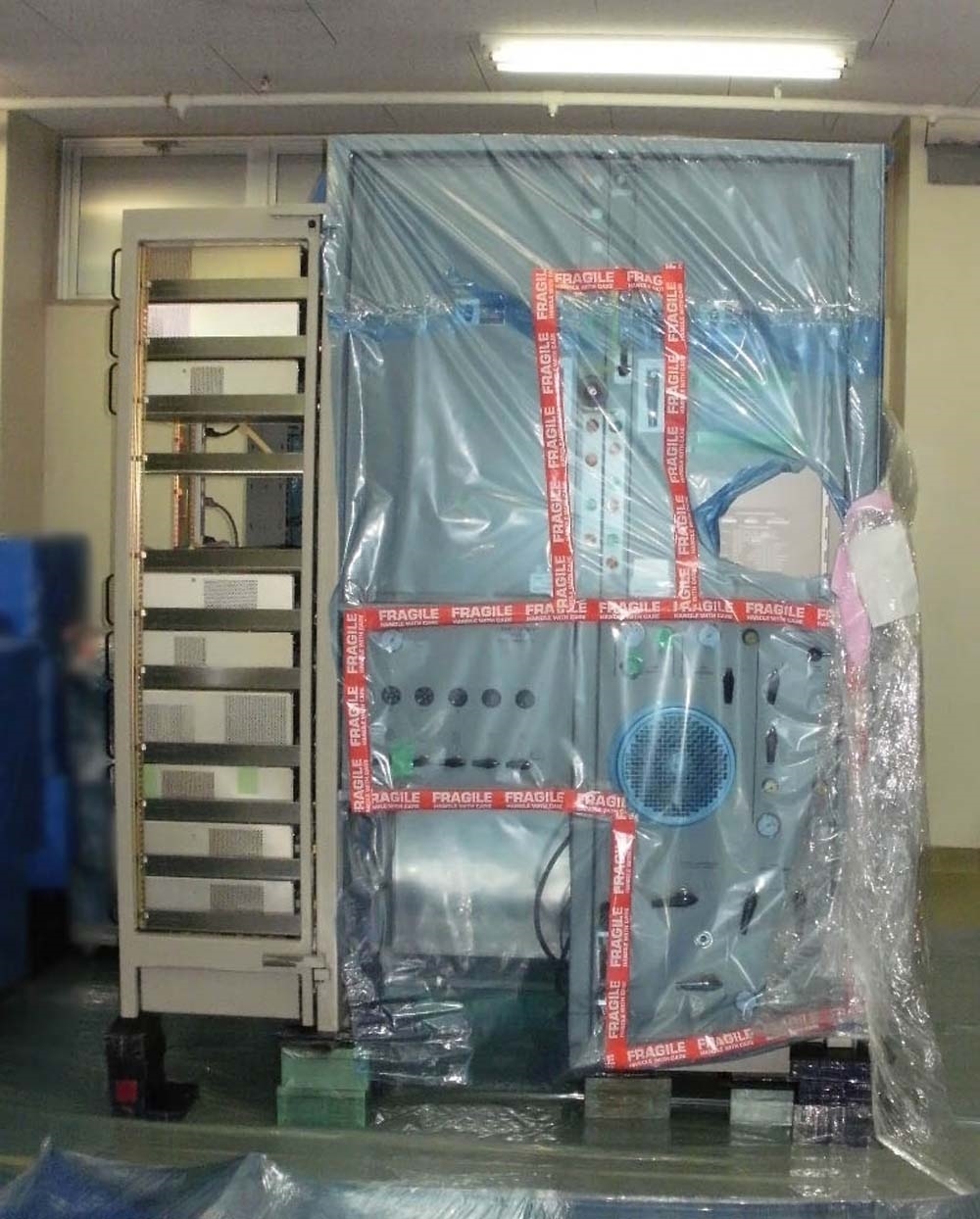

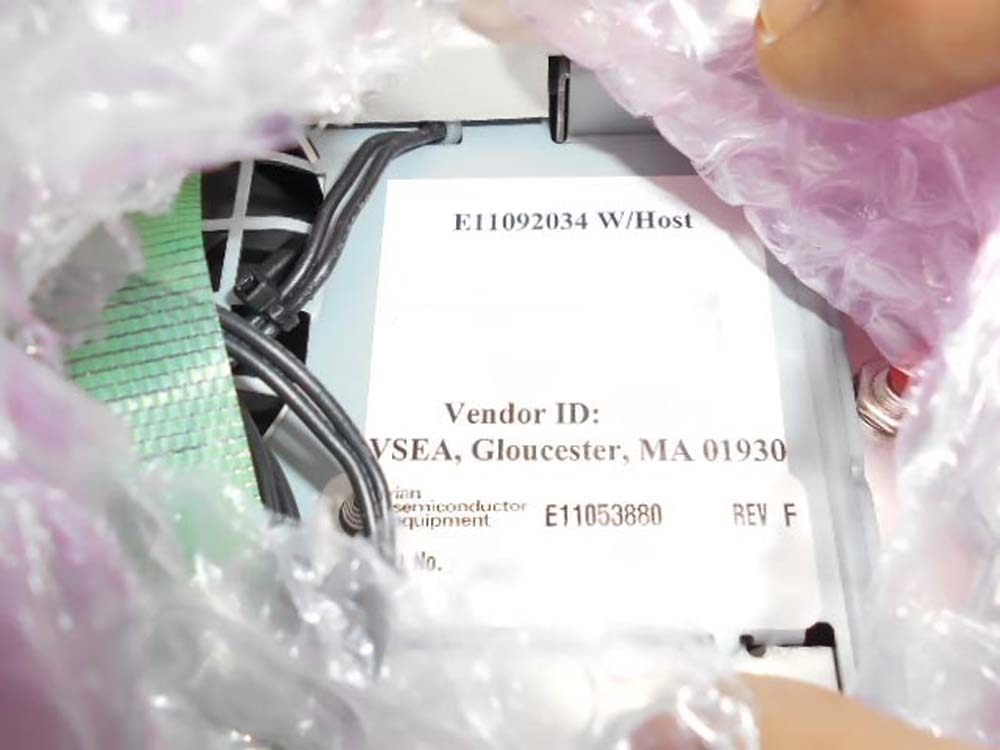

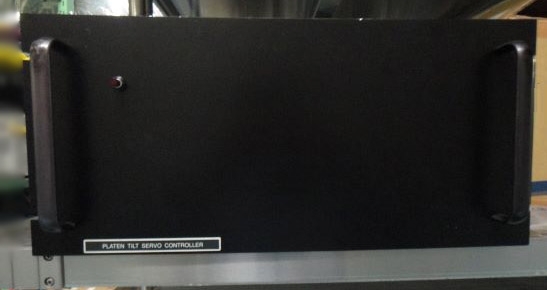

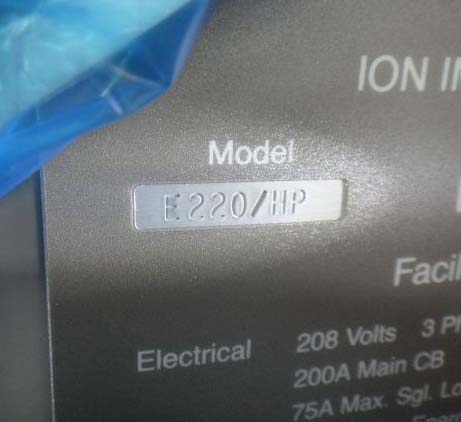

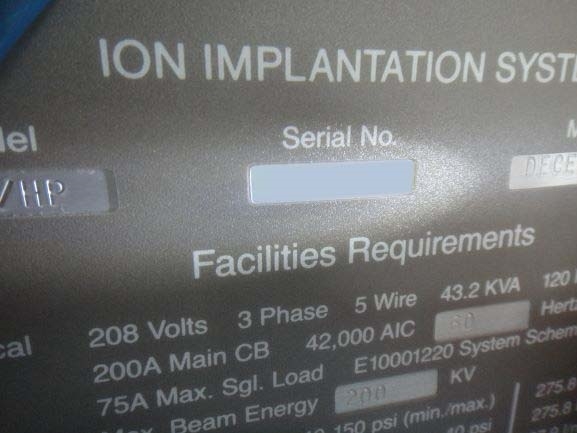

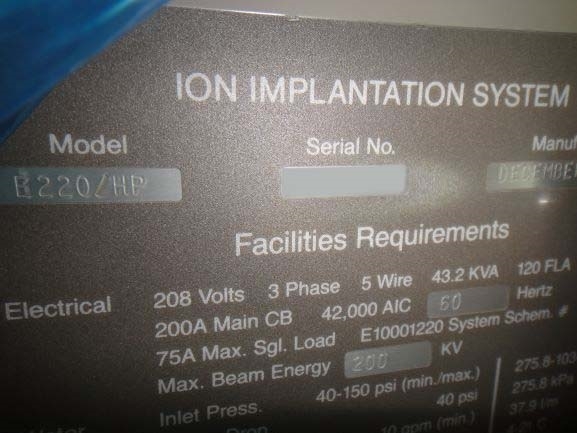

Used VARIAN E220HP #9259892 for sale

URL successfully copied!

Tap to zoom

ID: 9259892

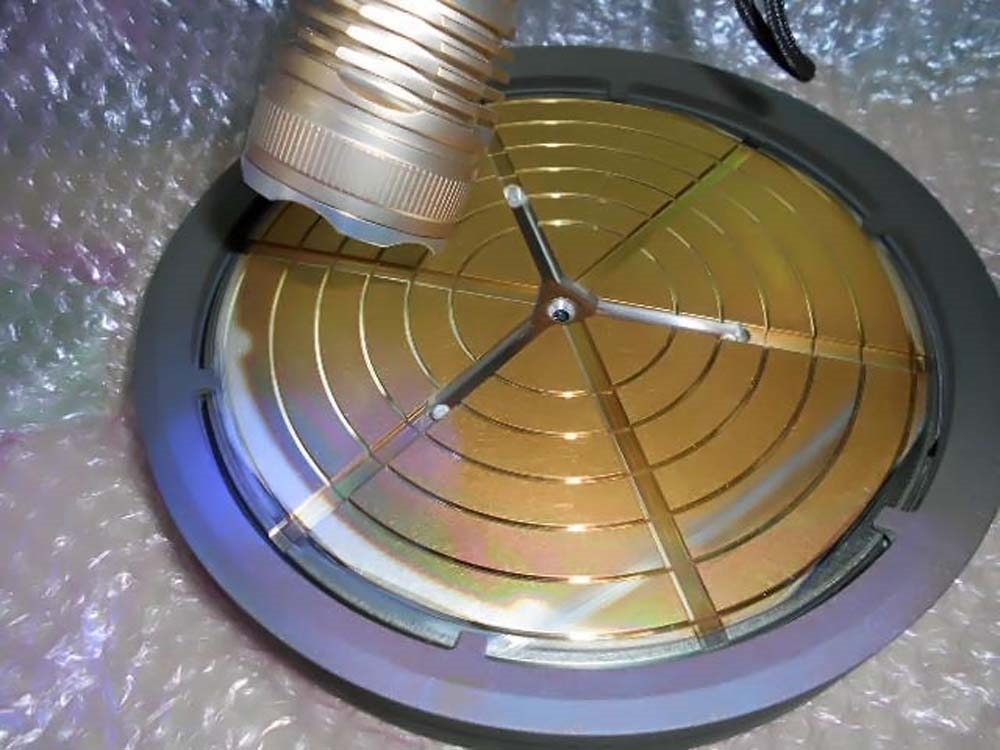

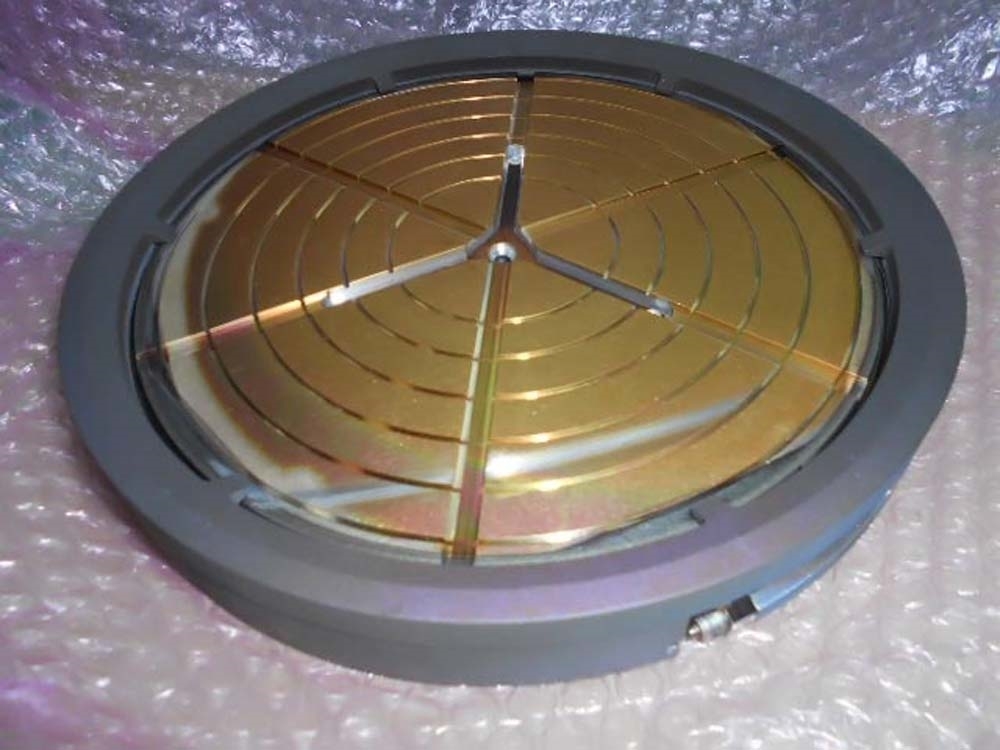

Wafer Size: 8"

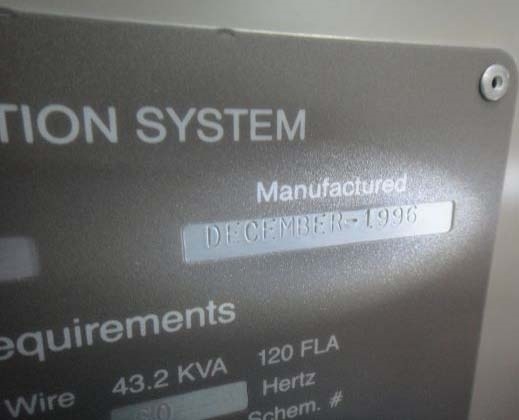

Vintage: 1996

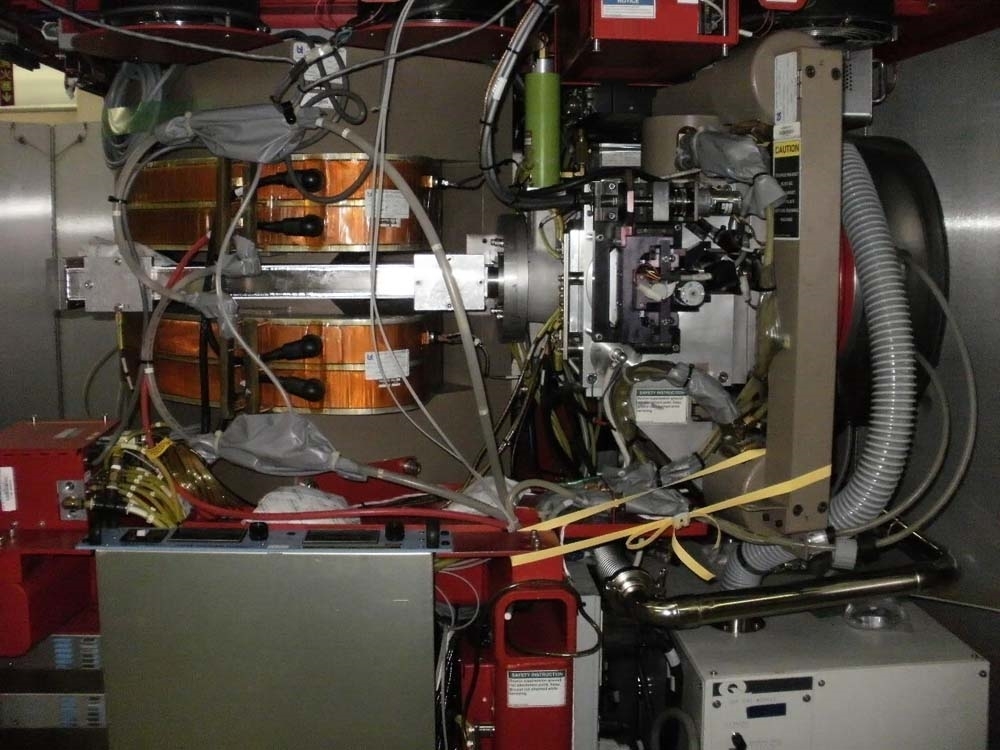

Ion implanter, 8"

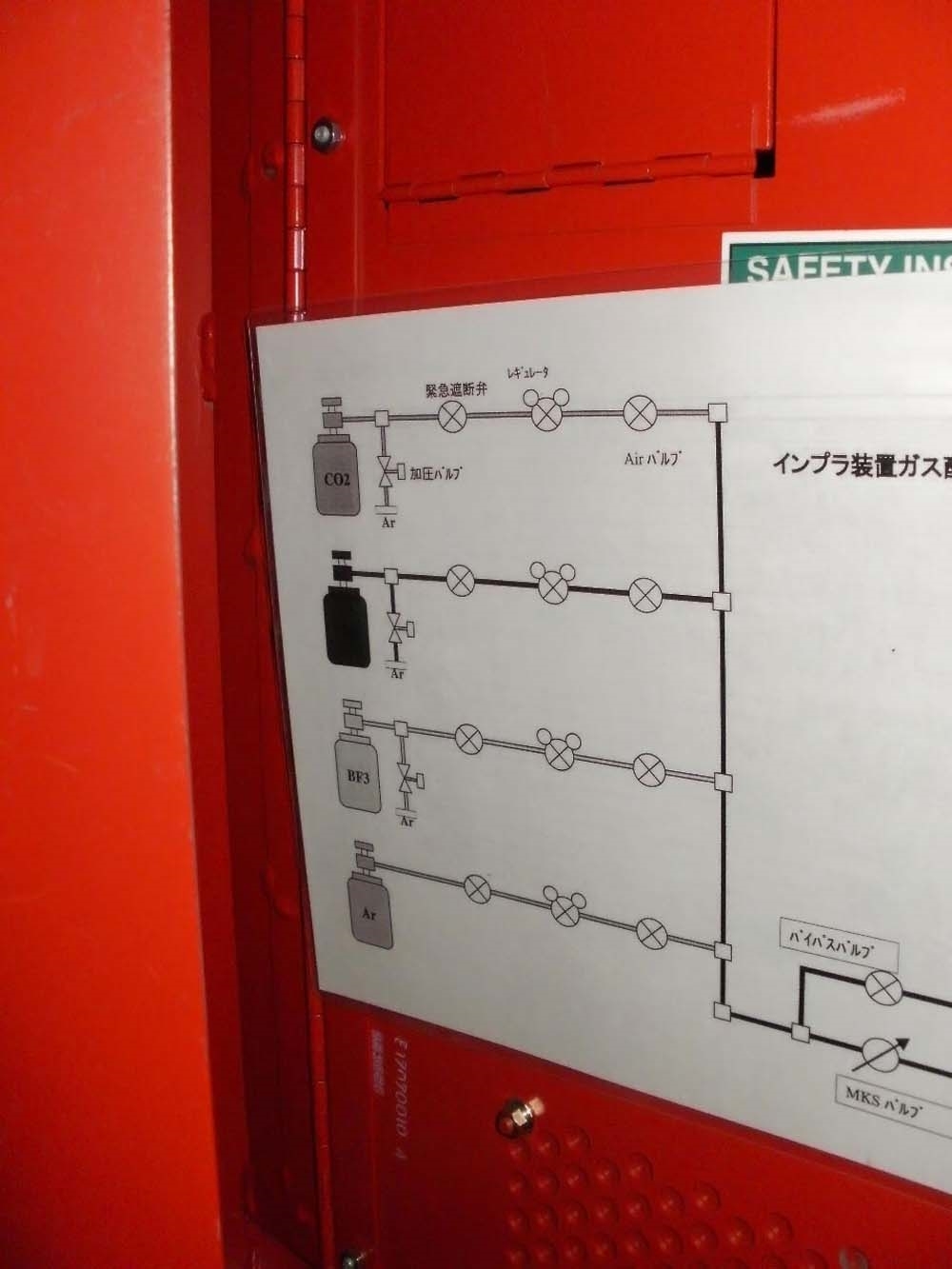

Gas cabinet:

Gas cylinder volume (liter): 1.0 Liter

Internal Ar

AsH3 Cylinder type: Vaporizer

PH3 Cylinder type: High pressure

BF3 Cylinder type: High pressure

Gas line purge

Vaporizer P.S

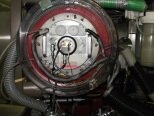

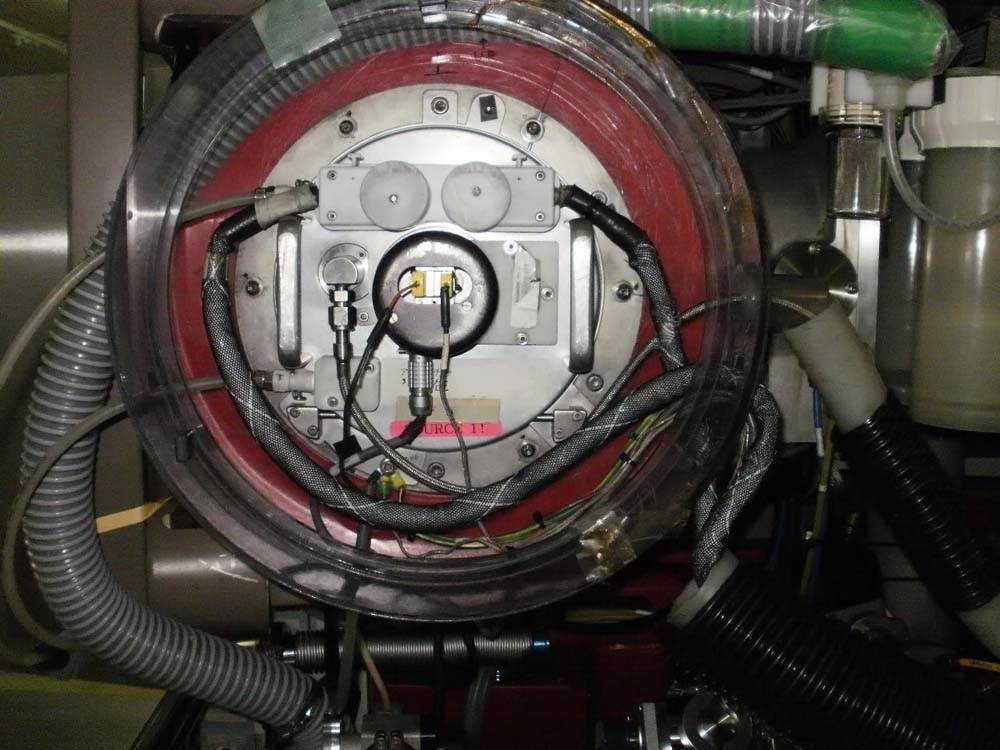

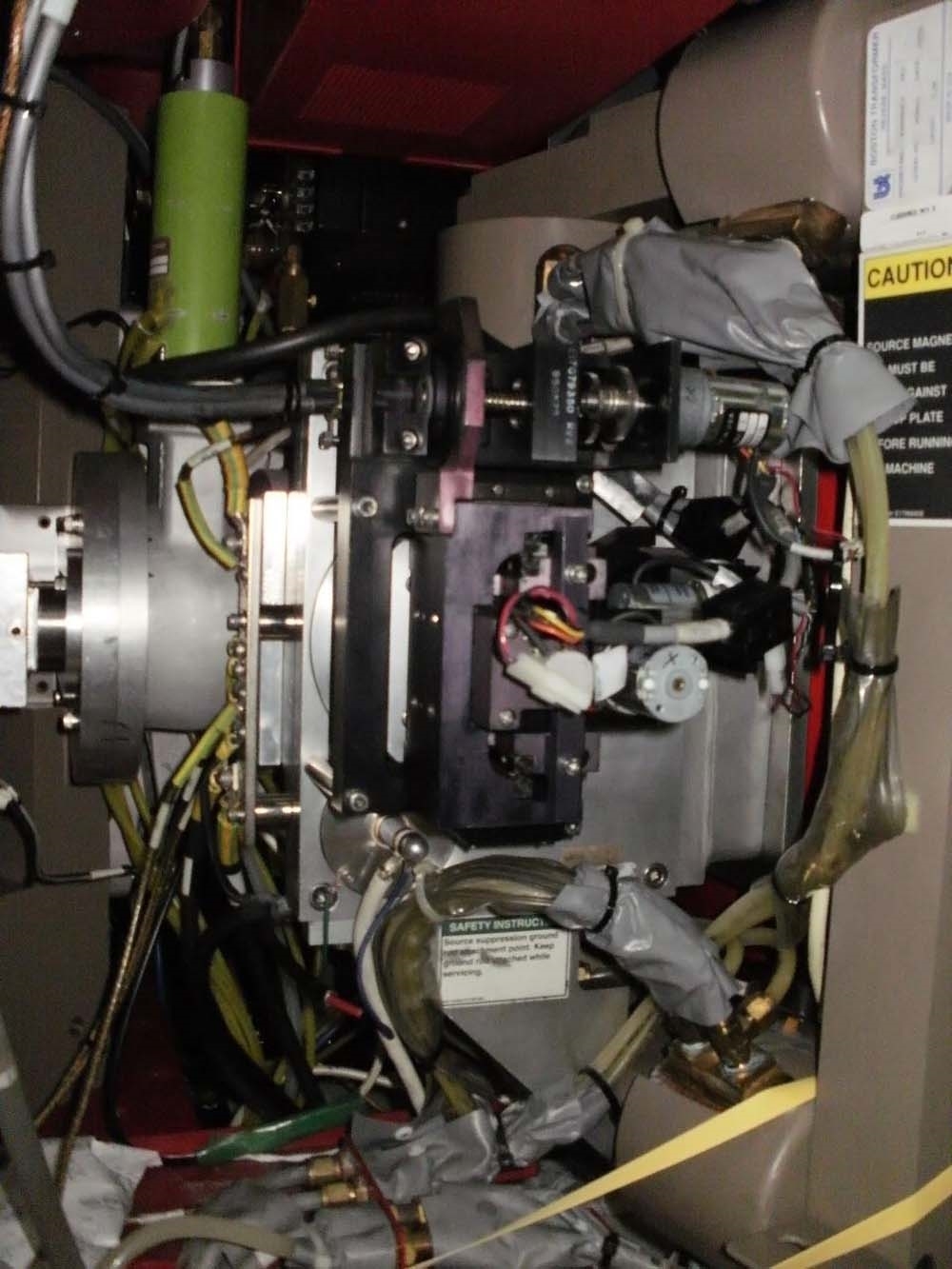

Source:

Source head type: Bernas

No reducer type 2 step

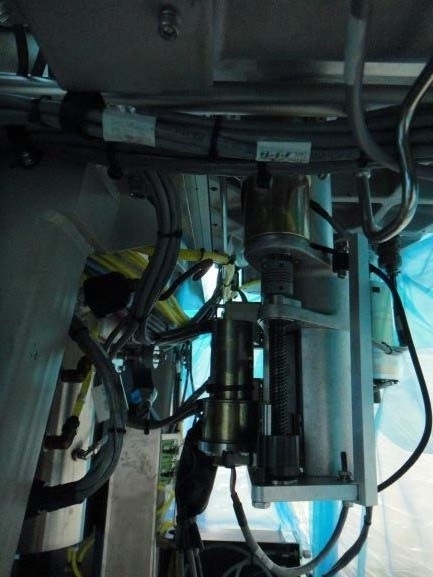

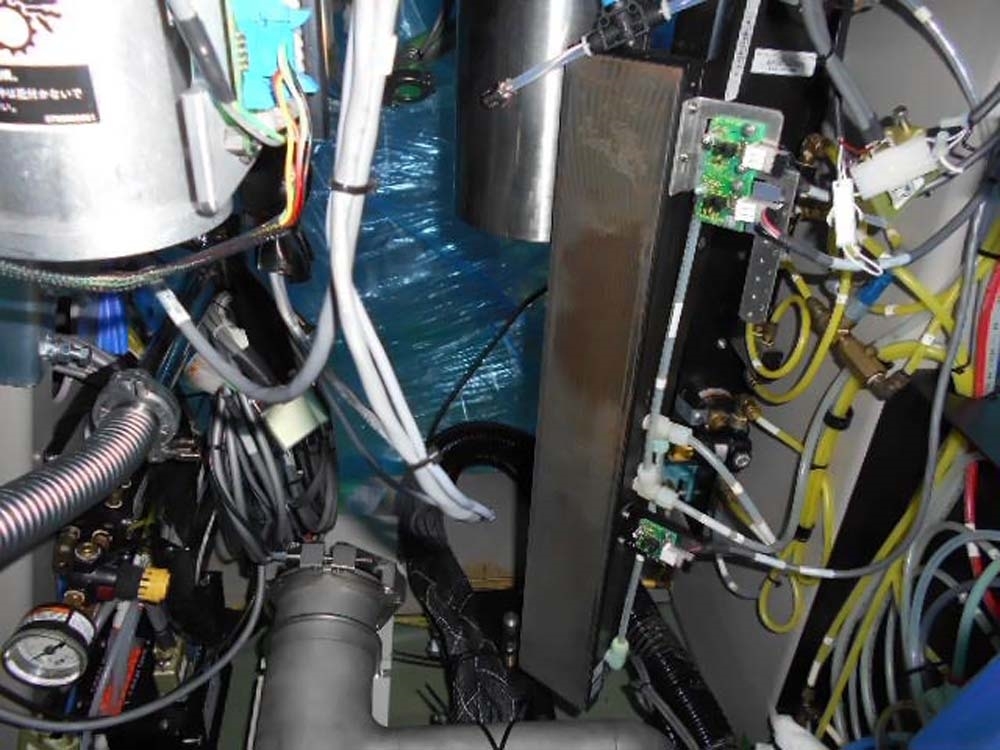

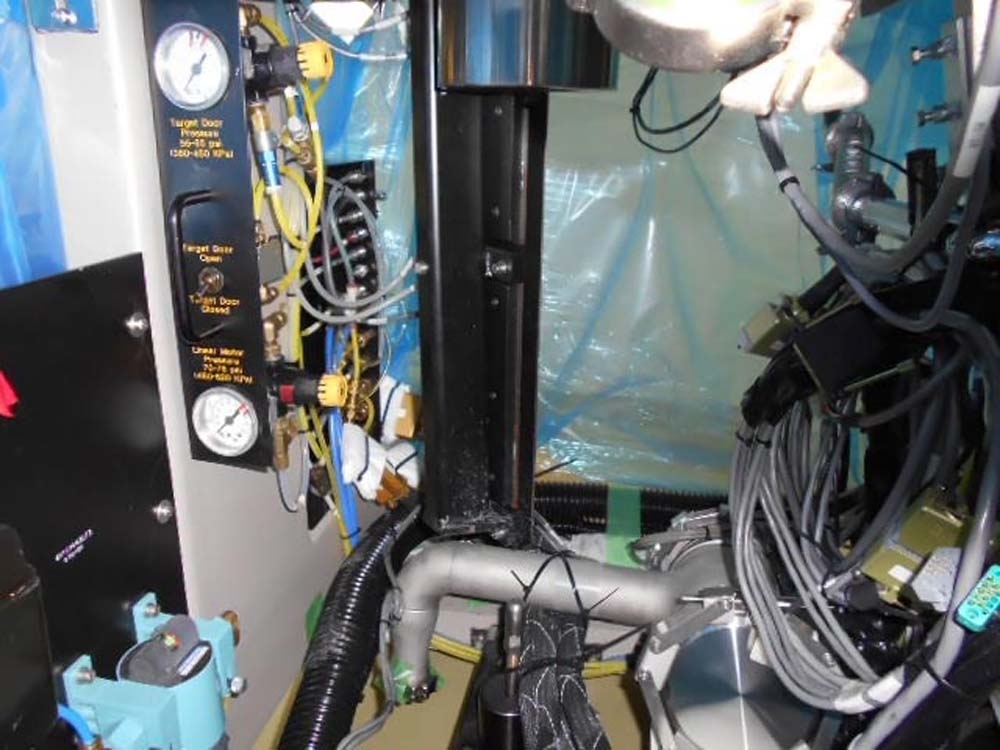

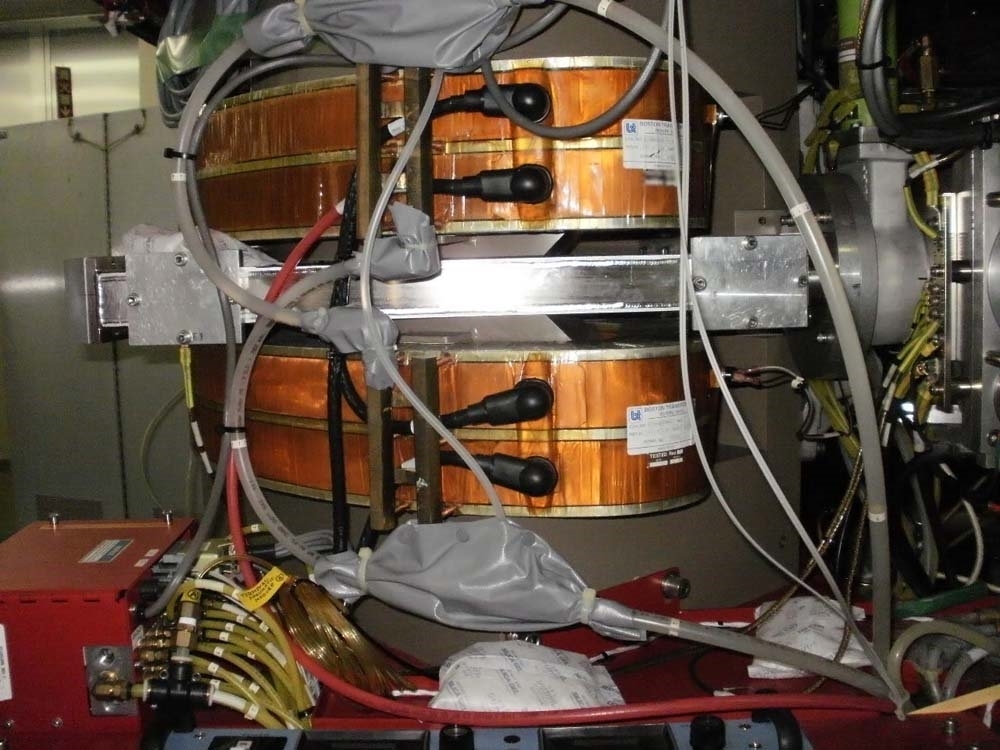

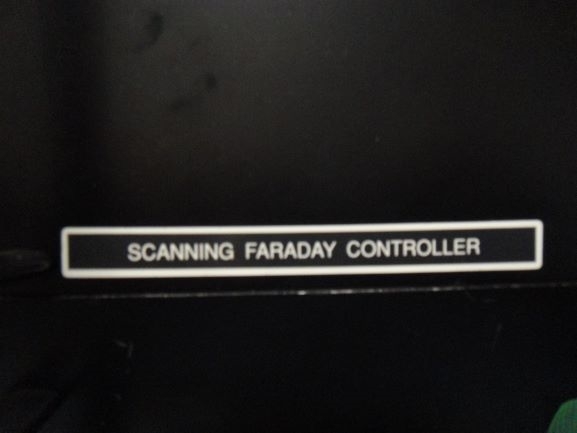

Beam line:

Scan generator: 20 kV

Mirror: 30 kV

No automatic graded decel relay and P/S

No hall probe

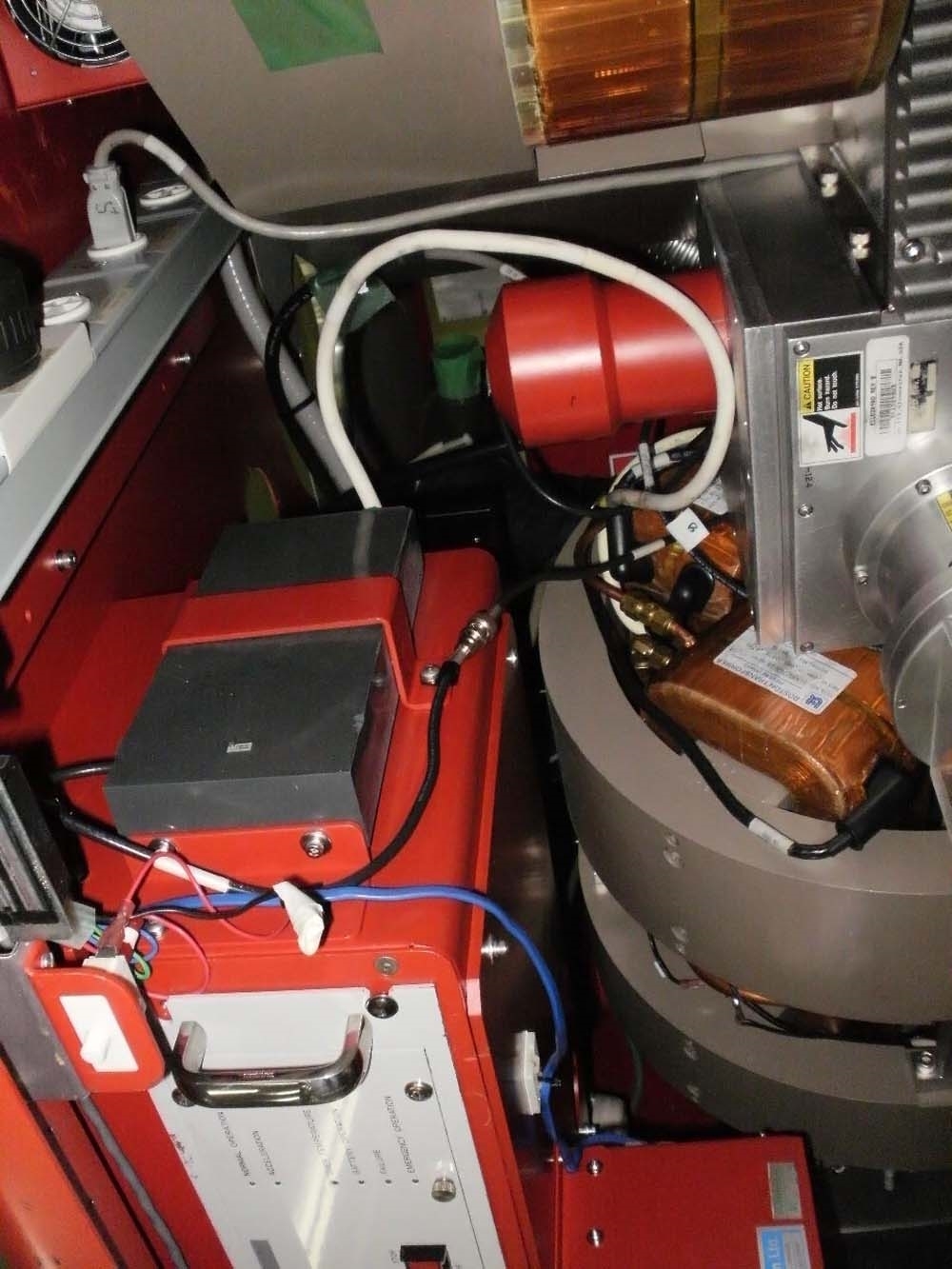

End station:

Old platform

M-Clamp

Three light signal tower

VESDA Smoke detectors

Service monitor

No control computer CVCF

No video viewing of wafer loading

Accessory:

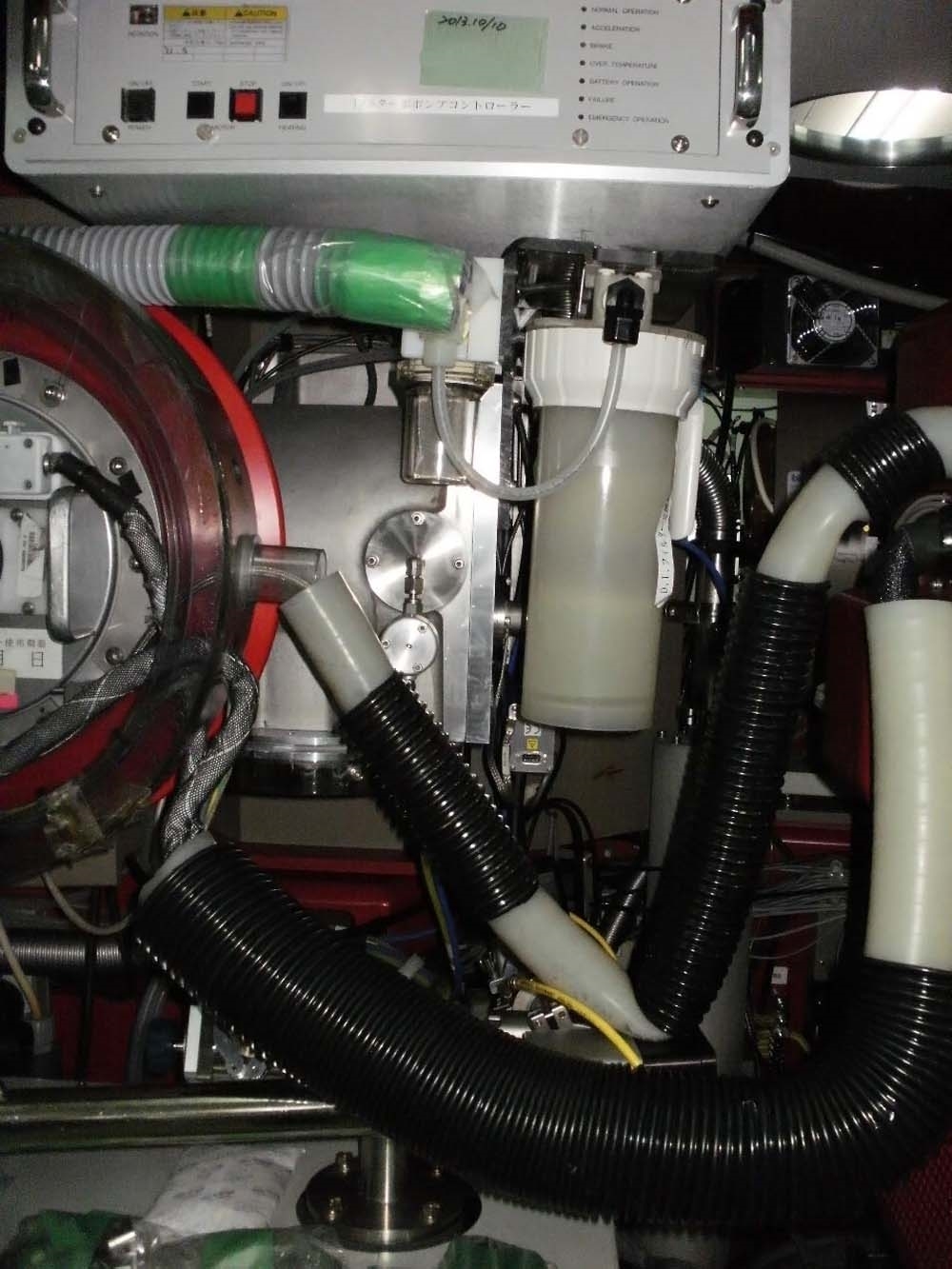

STP-1000C Source turbo pump

STP-300C Analyzer turbo pump

STP-1000 Beam line turbo pump

QDP80 Source rough pump

QDP40 Stage pump

QMP250/QDP40 End station pump

SUZUKI SHOKAN A250F Target cryo pump

SUZUKI SHOKAN A100L Load lock pump

SUZUKI SHOKAN C300 Cryo compressor

No remote PD

Vaporizer power supply missing

1996 vintage.

VARIAN E220HP is a high precision ion implanter and monitor designed for implantation of precise doses of ions into semiconductor materials. It is a versatile, automated equipment that can be used for a wide range of implantation applications. The system comes equipped with a number of features that maximize efficiency and precision. VARIAN E220 HP consists of an ion source, an accelerator, a beam control unit, and a process chamber. The ion source creates and accelerates the implanted ions to precise energies. The ion source is equipped with vacuum and cryopumping systems, and a temperature controller for optimum implantation performance. The accelerator is designed to provide a high-energy beam of ions to the substrate. It can also be used for tuning the beam energy further downstream before implanting into the substrate. The beam control machine is designed for precise control of the beam angle and intensity. This tool also features an extractor that can precisely adjust the ion extraction and beam angle during implantation. The process chamber is constructed with a stainless steel enclosure, providing excellent protection against contamination and allowing precise control of process conditions. The asset has a highly automated user interface, which allows users to set up complex implantation processes quickly and easily. Parameters like ion elemental composition, ion energy and beam angle are all adjustable directly from the user interface. Furthermore, the model can be integrated with other systems through an external computer. This provides additional flexibility and precision when dealing with multiple implantation processes. E 220 HP is designed for maximum reliability and consistent performance. It is designed to withstand rigorous environmental conditions, such as temperature and humidity variations that occur in industrial applications. This ensures that the equipment will perform without interruption even in harsh working conditions. Additionally, the system is equipped with a number of diagnostic and monitoring systems that can detect and identify unit faults before they occur. E220 HP is an excellent choice for those who require precise implantation of ions into semiconductor materials. Its advanced control and automation systems provide maximum precision and efficiency, enabling users to maximize productivity. Its reliable performance makes it suitable for a wide range of industrial applications.

There are no reviews yet