Used VARIAN VIISta 810 HP #9191582 for sale

URL successfully copied!

Tap to zoom

ID: 9191582

Wafer Size: 12"

Vintage: 2002

Medium current implanter, 12"

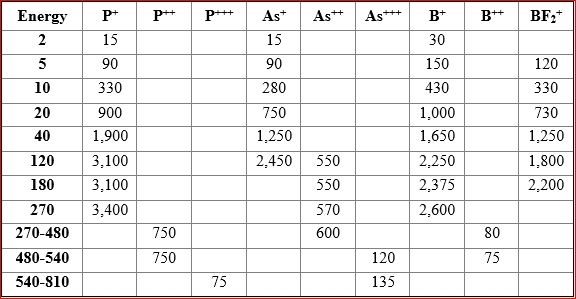

Dosing performance:

Range: 1E11-1E16 ions/cm2

Uniformity: ≤ 0.5% (For implant energies > 5 keV)

Repeatability: ≤ 0.5% (Wafer-to-wafer, cassette-to-cassette)

Implant angles:

Tilter: ± 60° in X and Y

Orientation: 0 - 360°

Rotation: Equivalent multi-tilt, quad mode

Angle control accuracy and repeatability:

Beam parallelism: ± 0.1°

X and Y Tilter: ± 0.1°

Orientation: ± 1.0°

Wafer cooling:

200 mm: ≤100°C at 800W Beam power

300 mm: ≤100°C at 900W Beam power

Particles: <0.05/cm2 (Mean value) for particle size > 0.16 µm

Metals contamination:

Heavy metals: ≤ 5 ppm (TXRF)

Aluminum: ≤ 5 ppm (SIMS)

Implant condition: 80 keV, 1e16/cm2

Ion mass resolution:

Energy > 5 kV, M/ΔM = 30

Energy > 20 kV, M/ΔM = 50

Energy > 80 kV, M/ΔM = 85

Mechanical throughput:

200 mm: > 270 WPH

300 mm: > 250 WPH (With buffer and 25 wafer cassette, Steady-state)

2002 vintage.

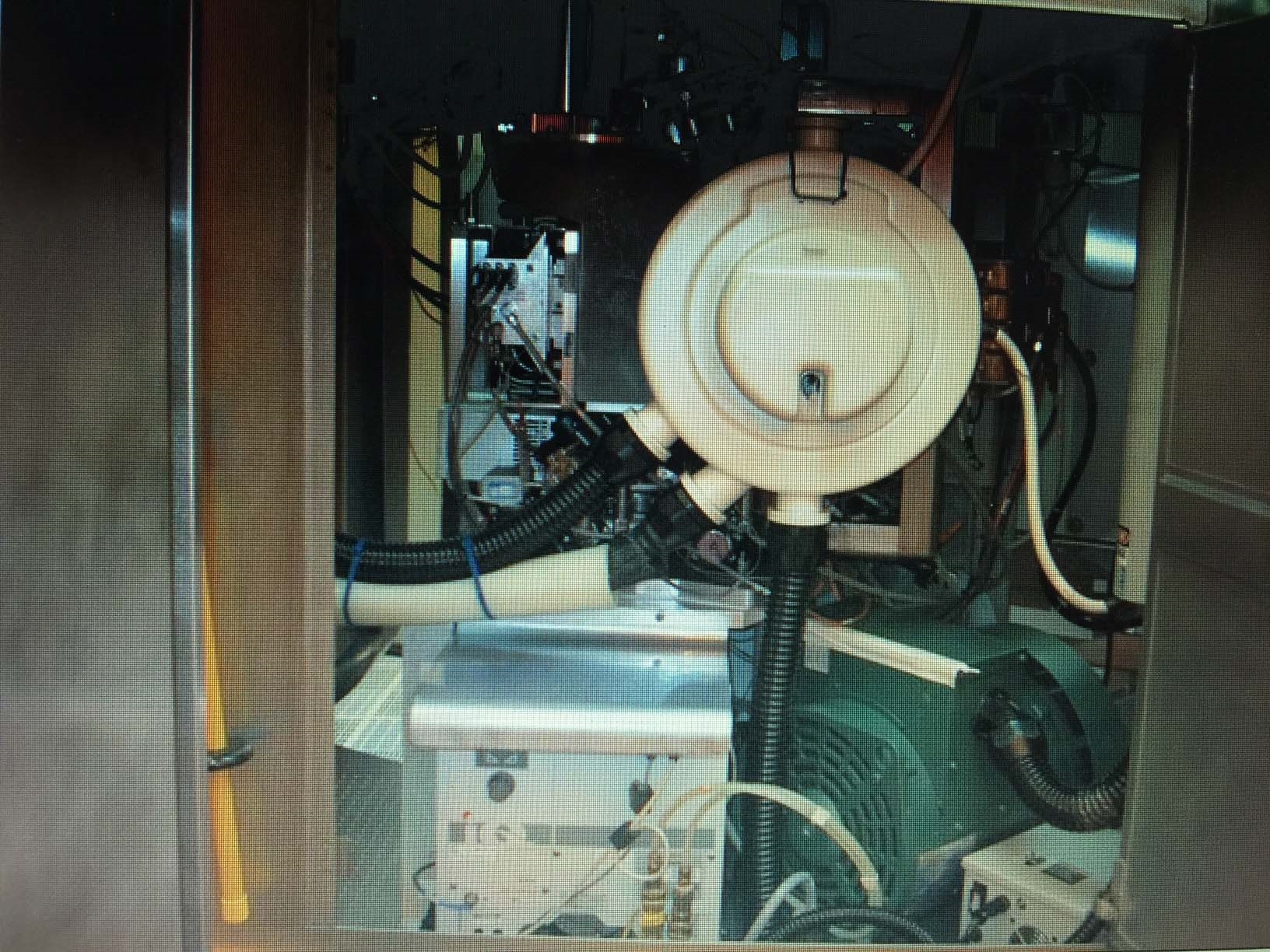

VARIAN VIISta 810 HP is an advanced ion implanter and monitor designed to provide exceptionally precise control over the implantation process. This implanter is intended for use in the semiconductor and electronic industries, and it is capable of providing rapid, repeatable, and reliable performance. VARIAN VIISTA 810HP is powered by a powerful drive equipment and a selection of proprietary software to perform advanced implantation operations. Its high-voltage source serves up to 3 Amps of implant power, with a selectable beam current range of 2-500 µA. This model can also safely accommodate temperatures up to 200°C, for operations that require higher temperatures. This implanter also features two separate beam analysis systems, one that measures the beam current and another that measures the angle. This allows for high accuracy implantation operations and enables advanced processes such as selective emitter doping and steep angle implantation. In terms of performance, VIISta 810 HP has an excellent throughput rate, achieving an implantation throughput of up to 400,000 wafers per hour. Its high speed is partially due to its new feed-through corrosion pad design, which prevents particle build-up and ensures high-quality implants. The implanter also features a remote monitoring system, allowing users to access the instrument's data and make adjustments remotely. This feature also enables convenient remote diagnosis and repair of the unit when needed. Overall, VIISTA 810HP is an advanced implantation machine that is designed to provide superior implantation accuracy and quality control in the semiconductor and electronic industries. It features high-voltage, high-power operation and two separate beam analyses, as well as a remote monitoring tool and impressive throughput rates. This implanter is sure to be a reliable and cost-effective tool for any industrial implantation operations.

There are no reviews yet