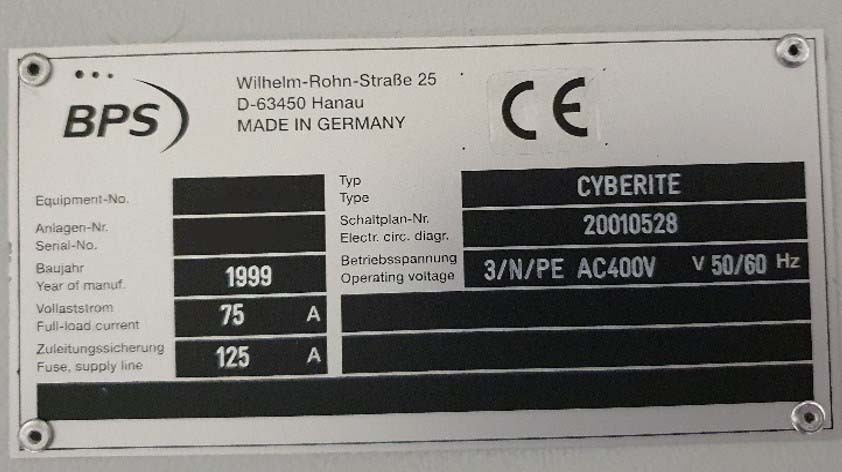

Used BALZERS / BPS Cyberite #9363567 for sale

URL successfully copied!

Tap to zoom

ID: 9363567

Wafer Size: 5"

Vintage: 1999

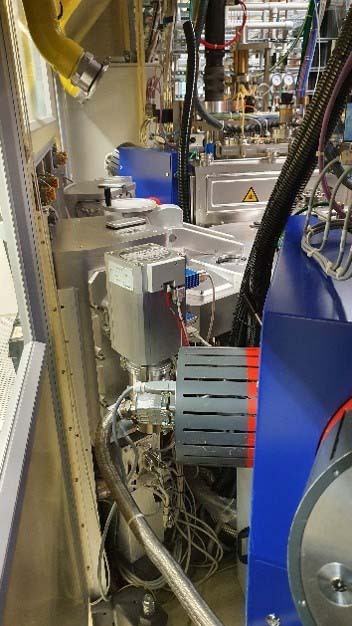

Ion Beam Deposition (IBD) system, 5"

(2) Chambers

(6) Targets

BROOKS Robot cluster handling

CTI-CRYOGENIC On-Board pumps

1999 vintage.

A BALZERS / BPS Cyberite is an ion milling equipment used to fabricate microstructures into surfaces. It is a powerful tool for nanofabrication that enables the etching of metals, ceramics, and polymeric materials. The system is based on a vacuum chamber with two large electron guns placed at either end, and a plasma source in the middle. The cathode guns generate an ion beam which scans across the surface of the sample and causes energy to be released from the sample material in the form of ions. The plasma source further accelerates and directs the ion beam, allowing for controlled modification of the surface. The ion beam also produces physical etching of the sample surface, which is assisted by the addition of gas to the chamber and is controlled via the unit's computer interface. The sample is mounted on a mounting arm that can be adjusted to precisely position the sample relative to the ion beam. The machine is capable of ion milling at milling rates of 50 nm/min up to 5 μm/min and can be used to create features with a minimum width of 0.5 nm. BPS Cyberite is integrated with a precision vision tool for real-time imaging of the surfaces that are being modified by the ion beam. This imaging asset is designed for low-voltage operation and can detect feature sizes down to 0.1 nm. This feature is particularly useful for quantitative imaging of features, which may be used to evaluate the efficacy of the ion milling process. The model is also equipped with an automated sample transport equipment for loading and unloading samples. This transportation system consists of a number of conveyor belts which allows for the transfer of samples from the laboratory to the ion beam chamber as well as for the removal of milled samples. This transport unit is also used to shuttle samples between the stage for milling and an external analysis machine, such as a scanning electron microscope. To ensure a safe and clean working environment, BALZERS Cyberite has an integrated gas abatement tool. The asset incorporates air-purification and ionizing systems to ensure that the ion beam chamber and its surroundings remain free from any traces of toxic gases. This allows the ion-milling process to be conducted in a safe and controlled environment. Overall, Cyberite is an advanced ion milling model with a wide range of capabilities. It is useful for creating complex nanostructures and it can be used to fabricate surfaces with a minimum feature size of 0.5 nm. Its automated transport equipment coupled with its vision system make it an ideal choice for research and engineering applications.

There are no reviews yet