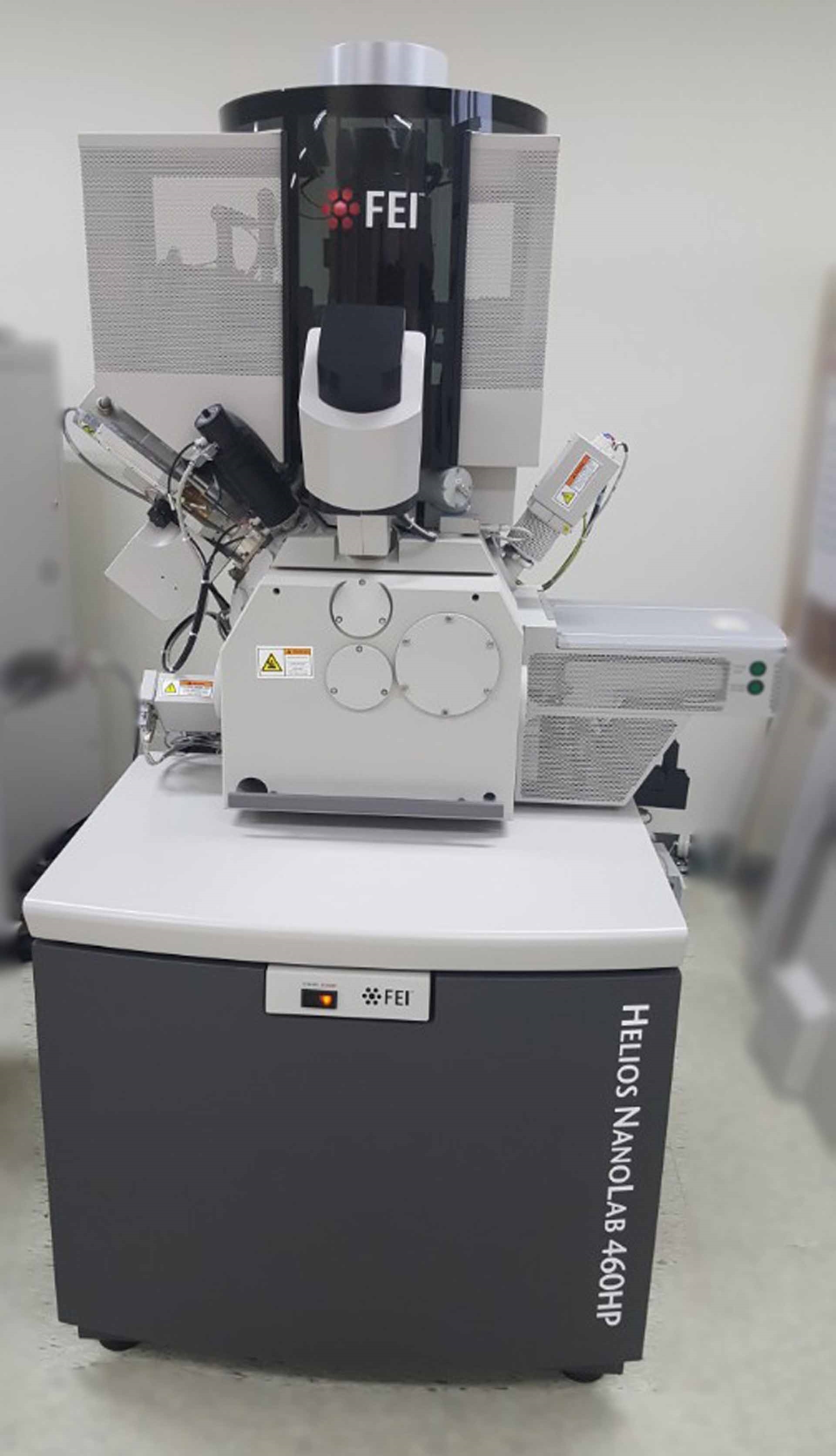

Used FEI Helios NanoLab 460HP #9192090 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9192090

Vintage: 2014

Dual beam system

X-Ray spectrometers (EDS / WDS)

With resolution down to 30 nm

Specification:

Electron source:

Schottky thermal field emitter

Ion source:

Gallium liquid metal, 1000 hours

Landing voltage:

20 V – 30 kV SEM

500 V – 30 kV FIB

SEM Resolution:

Optimal WD:

0.6 nm at 2–15 kV

0.7 nm at 1 kV

1.5 nm at 200 V With beam deceleration

Coincident WD:

0.8 nm at 15 kV

0.9 nm at 5 kV

1.2 nm at 1 kV

FIB Resolution coincident WD:

4.0 nm at 30 kV (Using preferred statistical method)

2.5 nm at 30 kV (Using selective edge method)

EDS Resolution: < 30 nm On thinned samples

In situ TEM sample liftout: Easylift EX nanomanipulator

Stage:

(5) Axes all piezo motorized

XY Motion: 100 mm

Quickflip shuttle

Sample types:

Wafer pieces

Packaged parts

TEM

Grids

Whole wafers: Up to 100 mm

Maximum sample size:

Diameter: 100 mm

User interface:

Windows GUI

With integrated SEM, FIB, GIS, simultaneous patterning and imaging mode

(3) LCD Monitors: 24" Widescreen

Key options:

Beam chemistry:

Standard gas injection systems

Multichem gas delivery system

Hardware:

EDS

WDS & EBSD Analysis: No

2014 vintage.

FEI Helios NanoLab 460HP is a high-performance, high-precision ion milling equipment designed to achieve nanoscale fabrication of a variety of materials. It utilizes energetic ions to quickly and precisely remove surface material from substrates. This ion milling system is capable of milling materials down to the nanoscale and can be used for a wide range of technical applications. The unit's dual beam FIB/SEM configuration combines field-emission scanning electron microscopy (FESEM) and focused ion beam (FIB) technology. The FIB can be used to mill, create structural features, and etch complex patterned structures on a substrate. Helios NanoLab 460HP allows for substrate temperatures up to 650°C, enabling a wide range of materials processing applications. The machine has a mass analysis capability that is capable of real-time monitoring of mass loss during milling; this is an invaluable tool for controlling and altering the uniformity of milled structures. The tool features a unique three-dimensional tilt stage to facilitate milling at high angles. It has also been designed for high-precision navigation, allowing for precise targeting of milling operations. This minimizes the amount of material removed from the substrate during milling operations, and helps reduce potential device damage caused by collateral material removal. FEI Helios NanoLab 460HP also has a feedback control asset to facilitate process optimization and monitoring. This feature enables users to monitor the condition of samples during processing, as well as monitor milling rates. All of these features contribute to the model's overall higher control over the milling process. Helios NanoLab 460HP is designed to be customizable, and the equipment can be co-optimized with other tools such as etching and deposition systems to meet specific customer requirements. The system can also be integrated with other tools such as data storage, analysis and visualization systems to analyze milled structures and samples. FEI Helios NanoLab 460HP is a revolutionary nanofabrication unit allowing for precise control and material removal down to the nanoscale. This machine can be used across a wide range of industries and applications, allowing for high-precision fabrications on a small scale.

There are no reviews yet