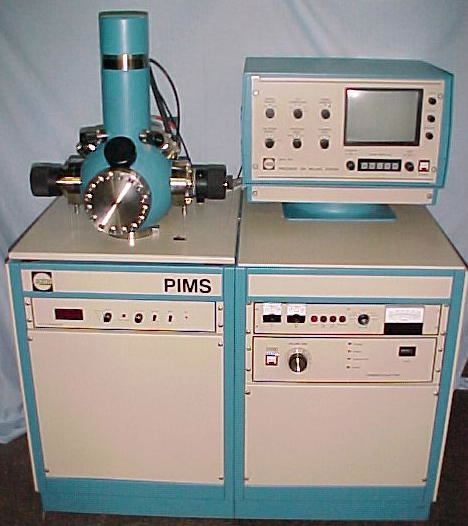

Used GATAN 645 #70882 for sale

URL successfully copied!

Tap to zoom

ID: 70882

Precision ion milling system for thinning of TEM specimens, complete with imaging system, eucentric goniometer stage and auto termination

The vacuum system includes:

air cooled Leybold Model TMP360 turbomolecular pump rated at 345 l/s with 6" OD conflat inlet and NT150/360 controller

Alcatel 2008A

7 CFM- direct drive backing pump

combination ion and two position thermocouple gauge.

GATAN 645 is an ion milling equipment with high-resolution polishing capabilities. This system is composed of four individual modules. The components of 645 includes a loadlock chamber, a gasketed vacuum chamber, an ion beam column, an eucentric stage, a vacuum unit and an ion beam control (IBC) machine. The loadlock chamber is composed of an aluminum frame containing a removable front panel, with a rail-guided door on either side. It is designed to reduce pressure changes and is also equipped with nonmagnetic rotating and sliding door seals to keep contaminants out of the vacuum chamber. GATAN 645 tool also includes a gasketed vacuum chamber, which is equipped with a central port. The central port allows access to the specimen chamber, which is filled with argon at a low pressure of 1 mbar. The eucentric stage is mounted on the gasketed vacuum chamber and is used to rotate and tilt the specimen. The ion beam column is designed to produce a uniform beam of ions by controlling the parameters such as current and energy. The column is equipped with a high-precision X-Y stage, which is used to control the beam direction and focus. The imaging asset is also located within the vacuum chamber. The IBC model is used to control the ion beam. This equipment includes an RF generator and a Dense Plasma Focus (DPF) optical cell to control the beam intensity, spot size, and beam current. The vacuum system components are located in the central port and on the rear wall of the vaccum chamber. 645 unit is especially suitable for thinning, which involves the use of ion beam to etch away thin layers of material, such as silicon oxide or other dielectrics, to create microstructures. It is also used as a polishing tool to produce smooth surfaces on metals, glass, and other materials. The ion milling process produces a uniform surface with a higher surface energy, allowing a better adhesion of thin films. GATAN 645 machine has a wide range of operating parameters, including beam current, beam energy, spot size, and angle of incidence. This tool, therefore, provides a flexible range of adjustable parameters, enabling applications such as thinning, etching, and polishing to be performed with great precision.

There are no reviews yet