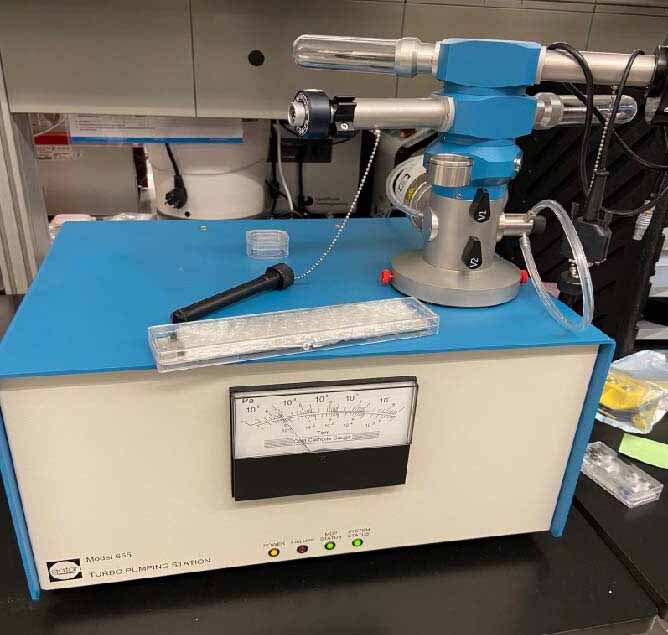

Used GATAN 655 #293595043 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293595043

Turbo pumping station

Self-contained

Compact

Benchtop pumping station

Sorb material in cooling

Cryo-transfer

Transmission Electron Microscope (TEM)

Diaphragm pump

Turbo drag pump technologies

Turbo drag pump permits

Storage capacity:

(4) Holders

(4) Modules.

GATAN 655 is an ion milling equipment designed for etching and material removal of a variety of materials. To achieve this, 655 uses an argon ion source to provide a focused argon ion beam, which is then directed at a target material to abrade, or "mill," the surface area. This process is known as ion milling. GATAN 655 uses a vacuum chamber, where the ion beam is focused, to their desired location or point of etching. The system's chamber is composed of UHV housings that are joined by modular flanges, allowing for easy setup and reconfiguration for different tasks. Inside the chamber, the ion beam is increased in energy by electron bombardment, allowing for higher etching rates when needed. 655 also includes a manipulator and micromanipulator to provide six degrees of freedom of movement within the chamber. Both can be used to precisely control the ion beam, allowing the user to focus it to any desired location. Also available is an in-chamber focus adjustment unit, which further increases the precision of the etch area. Different accessories can be used in GATAN 655 to optimize etch processes. For example, GATAN Infra View allows for a flux chamber to be attached to the machine. This provides a visual optical tool that allows users to monitor etching rate and accuracy. Similarly, a CryoVent asset can be used to cool etching targets, protecting fragile samples and increasing etching rates. 655 also includes an EIP Interface and user-defined size, shape, intensity, and density features, allowing for user customization. This can be used to produce a variety of etching and milling processes with high accuracy. Additionally, the model includes comprehensive diagnostics tools, including an in-situ spectrometer, allowing users to monitor the etching process in real-time. Overall, GATAN 655 is an advanced traditional ion milling equipment capable of producing high precision etching with a variety of process options, customization features, and monitoring features. The system's modular design and accessories offers increased process control and optimum performance.

There are no reviews yet