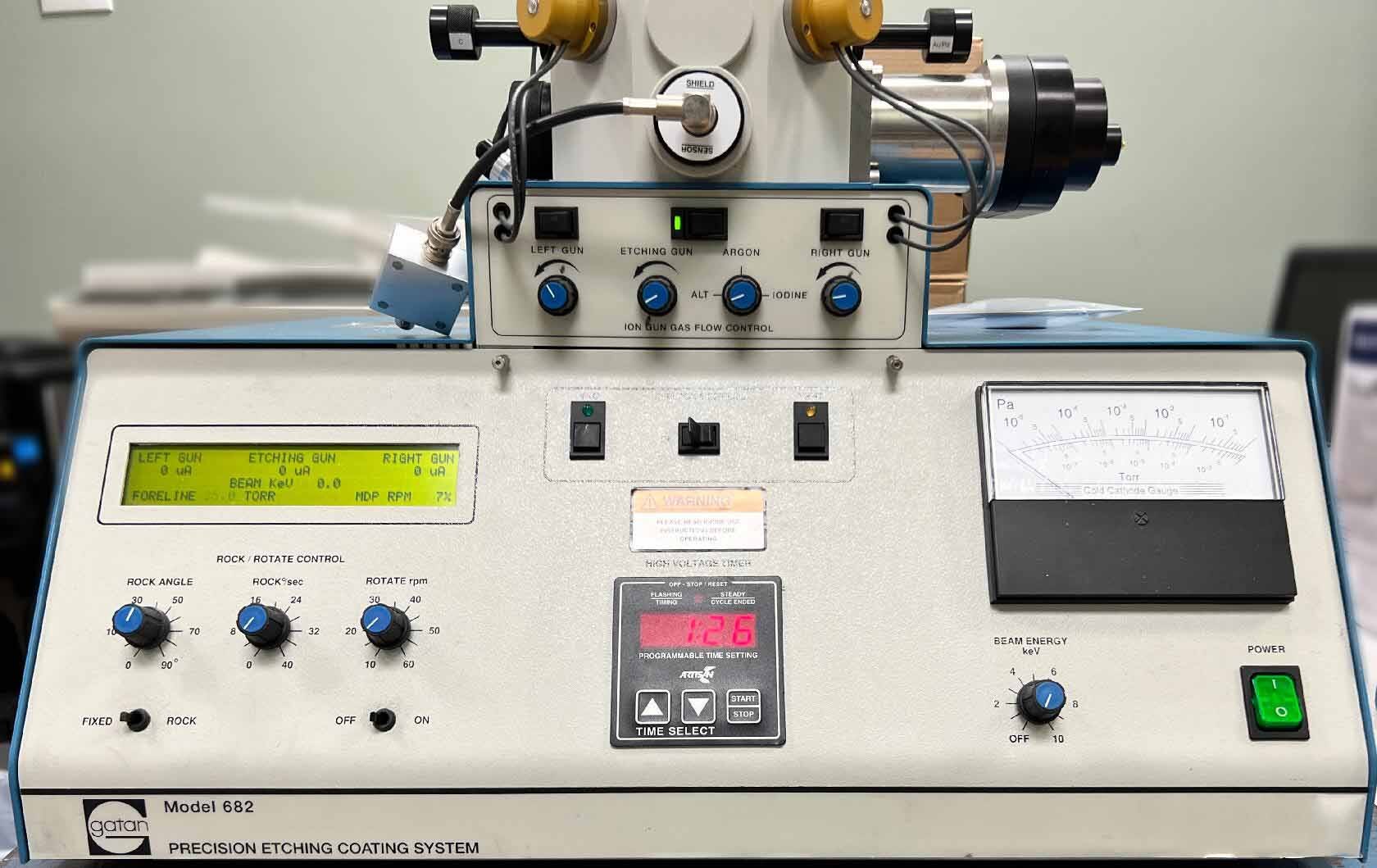

Used GATAN 682 #293648546 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293648546

Precision Ion Polishing System (PIPS)

MAXTEK TM-350/400

(3) Individual ion sources (ion energy 1-10KeV)

Etching area: 7-10 mm

Silicon etching rate 10 μm / hr

Tungsten 3 μm / hr for at 10.0 keV

Carbon coating rate 0.5Å / sec

Chromium 1.5 Å / sec at 10.0 keV

Uniform over 1" Diameter

(2) Dual target sets, selectable under vacuum

Target materials: Au, Au / Pt, Ag, C, SiO2, Cr, Ti, Al

Spare parts included:

Qty / Part number / Description

(1) / 682.82001 / Service manual

(1) / 682 / Service kit

(1) / 682 / Accessories kit

(1) / 691 / Accessories kit

(1) / 691 / Liquid nitrogen trap

(1) / 09811 / Chemical vials

(2) / 682.15200 / Pump spanner wrench

(2) / 09680 / Krytox grease

(2) / 682.11028 / Charge, carbon replacement

(1) / 682.19074 / reducer

(1) / 682.19075 / reducer

(2) / 681.19076 / Tri-Pod mount adapters

(2) / 682.19007 / Centering rings

(1) / 682.14080 / Complete O-Ring kit

(1) / 681-19083 / Adapter tube

(1) / 05530 / Cable coax.

GATAN 682 is an ion milling equipment designed for high-performance physical preparation of materials for transmission electron microscopy (TEM). It utilizes a high power inertial focusing ion source, generating a beam of argon ions which are used to sputter off a few nanometers of surface material from a sample on a MEMS programmable stage. 682 system features a variable angle vacuum chamber which is capable of accommodating a wide range of sample sizes and shapes, and a special inclinometer for adjusting the ion beam direction. The vacuum chamber is connected to GATAN Gas Control Unit (GCS), which provides flow control of gas and particles in the chamber. The machine also includes a motorized sample stage, advanced automated control software, and user-friendly GUI (graphical user interface). GATAN 682 generates spatially uniform, high quality milling results, primarily due to its improved design of the gas and ion beam control. The gas flow velocity is maintained by specially designed nozzles, and the electrical potential distribution in the vacuum chamber utilizes patented electrodes, allowing the ion beam to be precisely focused at predetermined angles to give uniform etch depth on large surfaces. Such advanced control tool and software allows for efficient and precise milling of the sample without manual adjustment. 682 is also equipped with a flexible pattern generator module, to allow for more precise, uniform etching patterns. The pattern generator module generates a pattern based on the shape of the sample, mask geometry and selectable processing parameters, such as etching, ion frequency and beam width. This module helps to ensure a uniform, accurate etch depth, even for complexly shaped samples. In addition, GATAN 682 provides advanced features such as a Radiation Tolerance Mode, allowing the user to adjust the milling settings when the sample is exposed to incoming radiation during TEM operation. It also includes a service counter, providing the user with information on total milling time, number of activated ions and average etching rate. Overall, 682 is a highly advanced ion milling asset with excellent precision and reliability. Its cutting-edge technology, innovative design, and wide range of features make it the ideal choice for physical preparation of materials to be studied by TEM.

There are no reviews yet