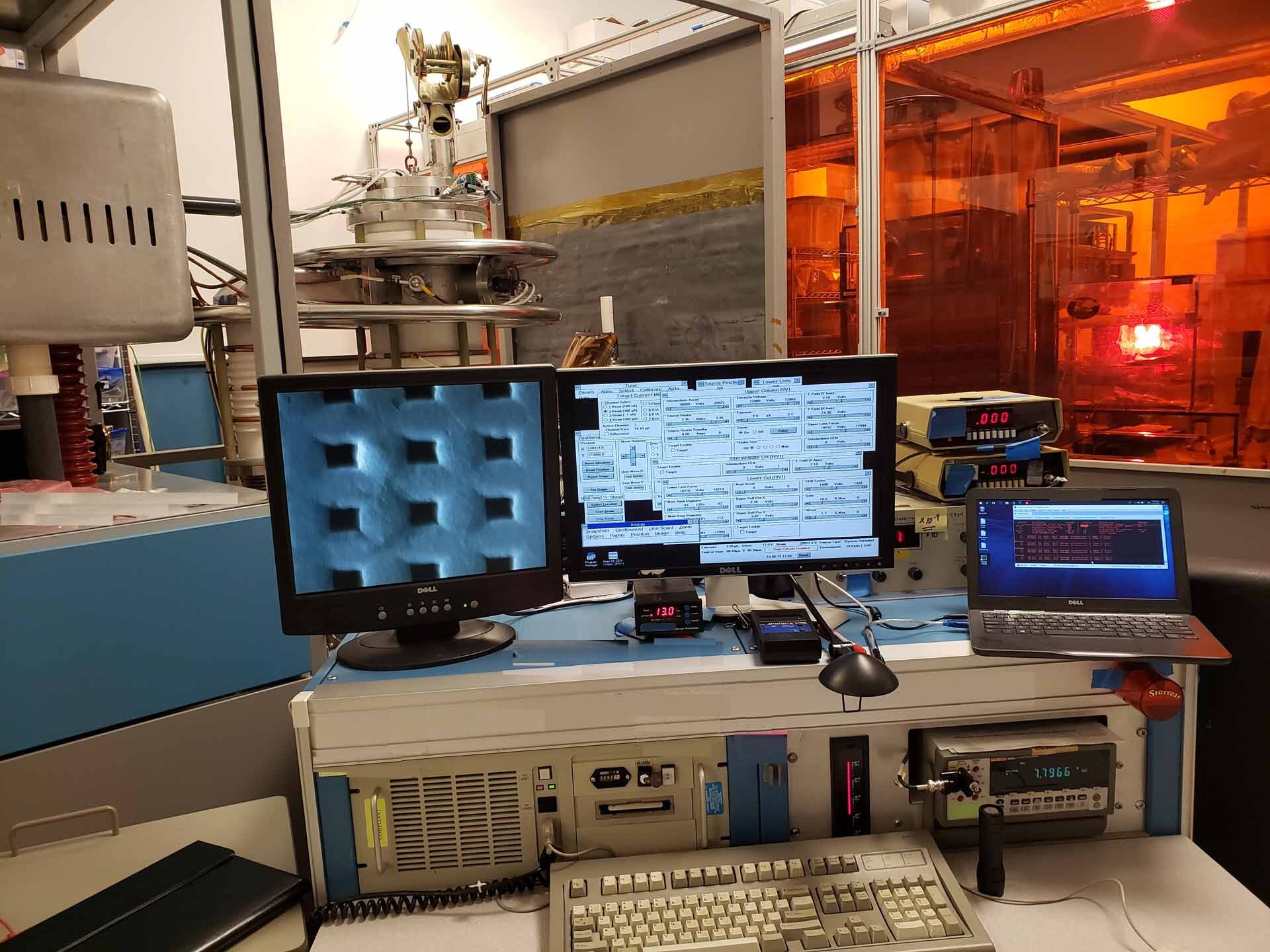

Used MICROBEAM Nanofab 150 #9172653 for sale

URL successfully copied!

Tap to zoom

ID: 9172653

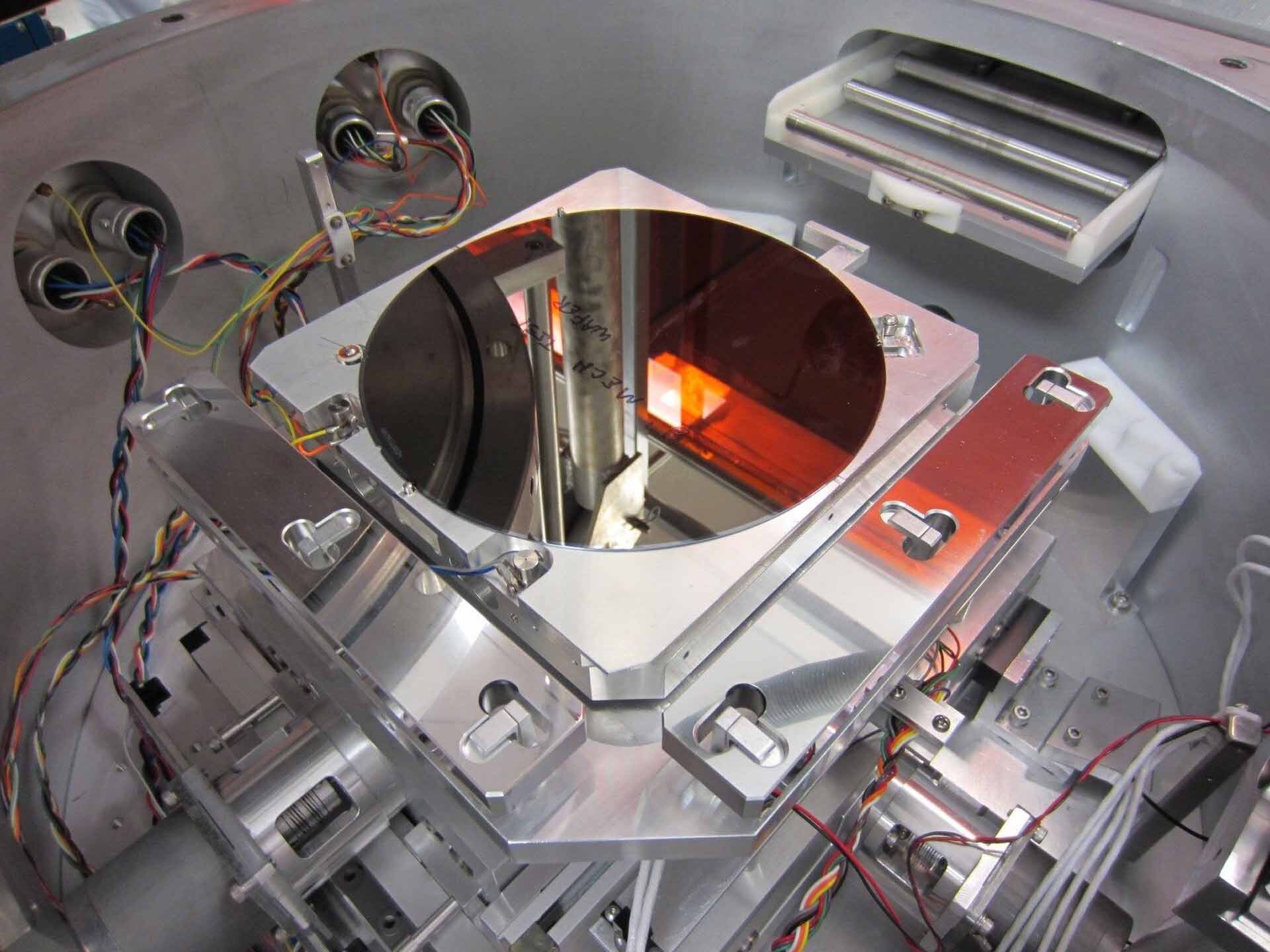

Wafer Size: 8"

Direct write ion beam lithography system, 8"

GDSII

Integrated laser position stage

Minimal beam spot size: 20nm

Energy: 4 -150 keV (300 keV double ionization)

ExB Mass filter

M/deltaM ≥ 50

Liquid metal ion sources: Ga, Si, Ge, In, Be, Au, As, B, Pd, Bi

Beam current density: Up to 5A/cm2

Computer controlled

Stepper motor driven substrate state: 165mm x 165mm travel

1 nm Resolution laser position monitor

Upgrade options available:

Advanced sub 10nm ion optics

Stainless steel system with 10 Pallet load-lock (6" wafer only)

8" wafer handling (2 pallet load-lock only)

General System Upgrade (GSU): Includes vacuum, computer, data handling software, interferometer

Ion sources: 5A/cm Ga, Si, Ge, In, Be, Au, As, B, Pd, Bi sources

Ion guns

Advanced Performance Gun (APG) and source.

MICROBEAM Nanofab 150 is an advanced ion milling equipment designed to process extremely small and sensitive surfaces with extraordinary precision. The system utilizes a focused ion beam which is sent through a column to deliver atomic level milling and etching of materials down to the sub-micron level. This process is fully automated, meaning it requires minimal user intervention during the operation process. The unit consists of three main elements: the ion gun, the gas box, and the process chamber. The ion gun is composed of a source of ions, an acceleration grid, and a collimator lens. The source of ions must be compatible with the material being worked on, and the acceleration grid and collimator lens combine to generate a collimated beam of ions; this beam can then be focused and accurately directed to the working area. The gas box is used to generate a controlled environment in the process chamber; it houses the gas source and provides a plane on which the material is placed. Lastly, the process chamber is where the milling and etching process takes place, as the beam interacts with the material on the gas box plane. The machine produces a finely controlled beam of ions which can accurately target the working material layer by layer. The result is a precise etching of sub-micron order which can be used to create extremely complex patterns and structures. Additionally, this operation can be automated and, with proper programming, can generate intricate patterns with great precision and speed. The use of inert gases also ensures that the material is not damaged by the process itself. Nanofab 150 is a very advanced piece of equipment designed for accurate milling and etching of delicate materials at the sub-micron level. It provides a high degree of precision and control for etching and microfabrication applications. The tool is fully automated and, with proper programming, can save time and increase production quality and throughput.

There are no reviews yet