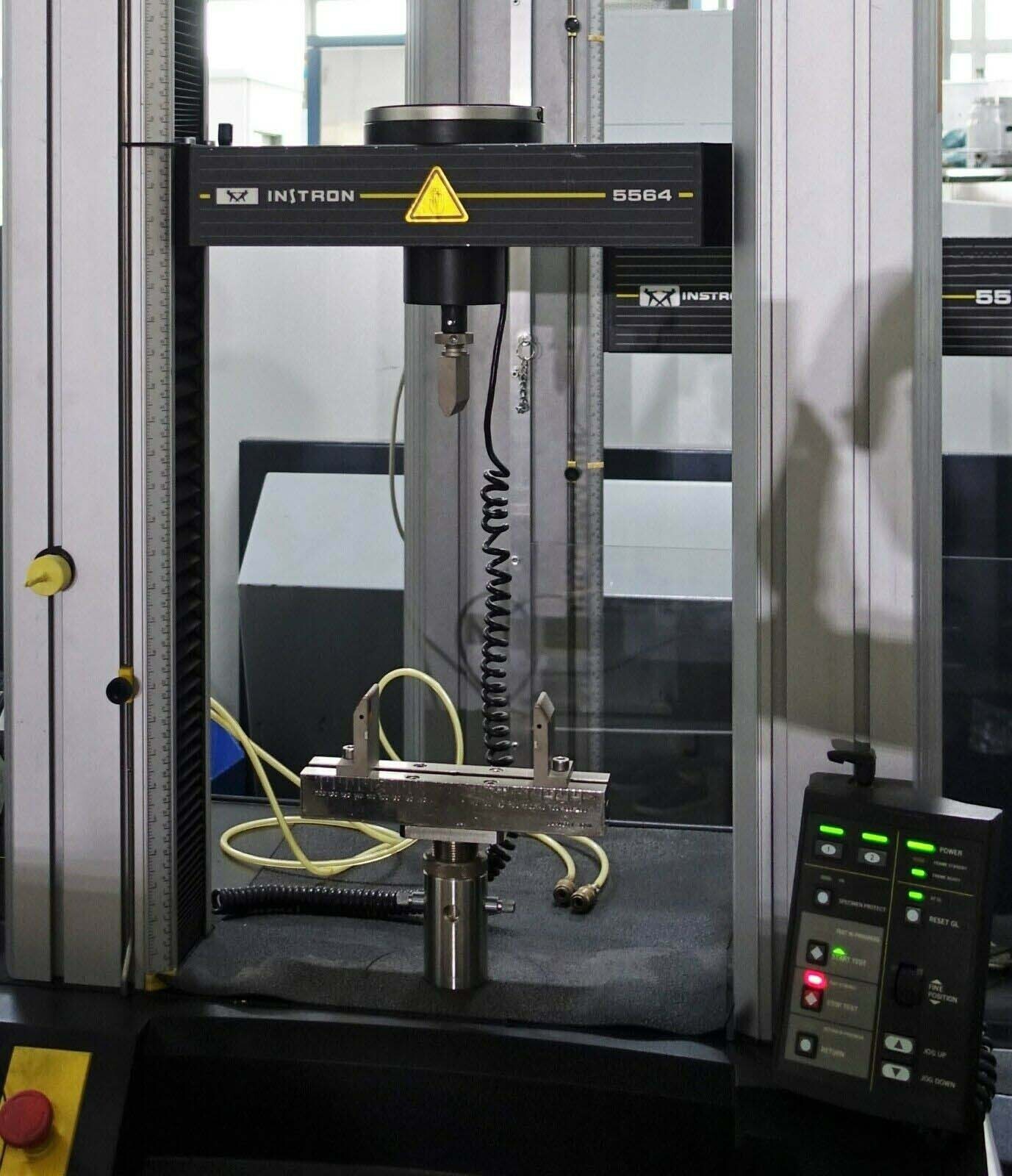

Used INSTRON 5564 #9316083 for sale

URL successfully copied!

Tap to zoom

ID: 9316083

Tensile tester

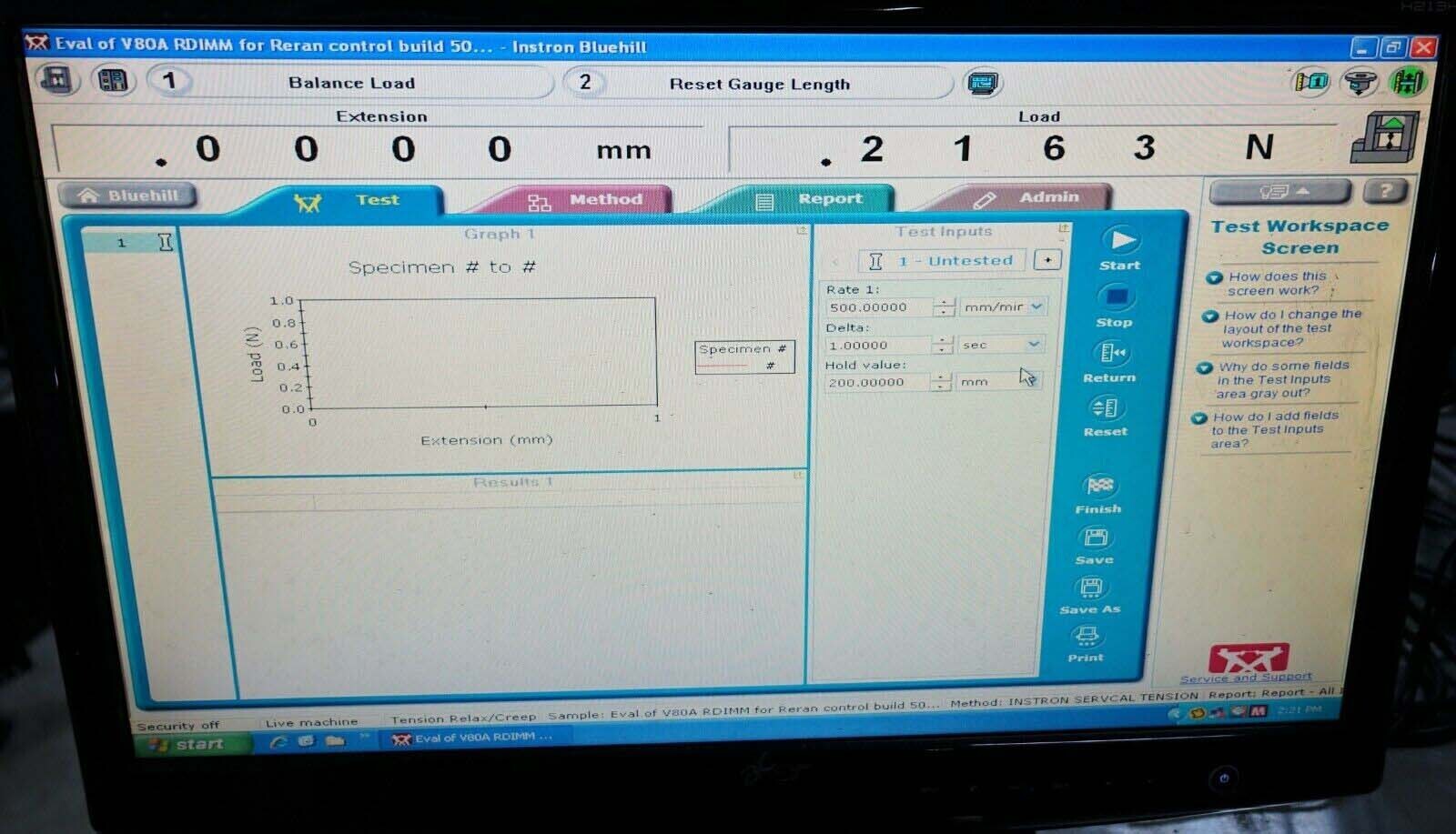

With computer

Drop-through static load cell, P/N: 2525-818: 2 kN, 80 mm

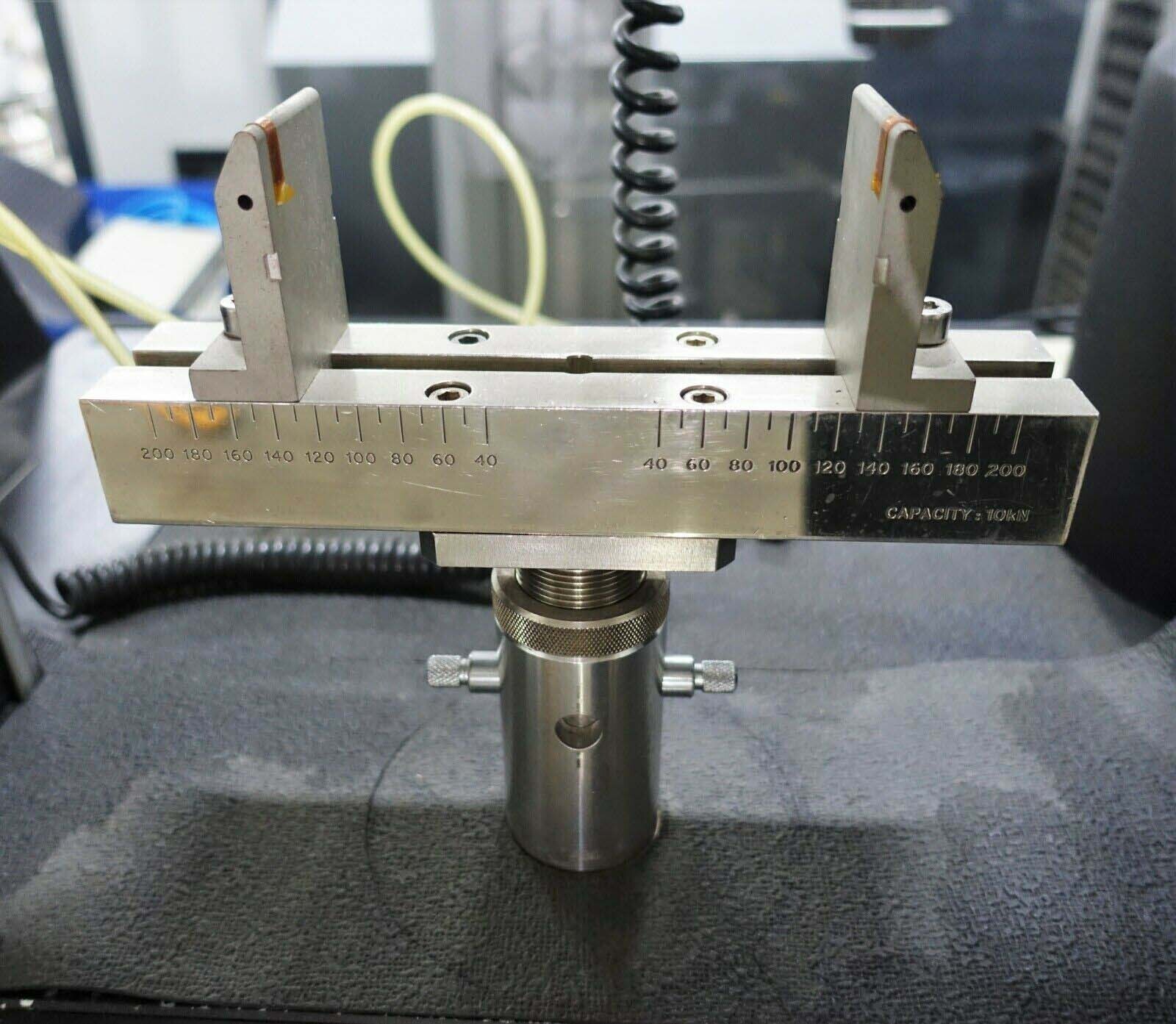

(3) Points flexure fixture: 10 kN

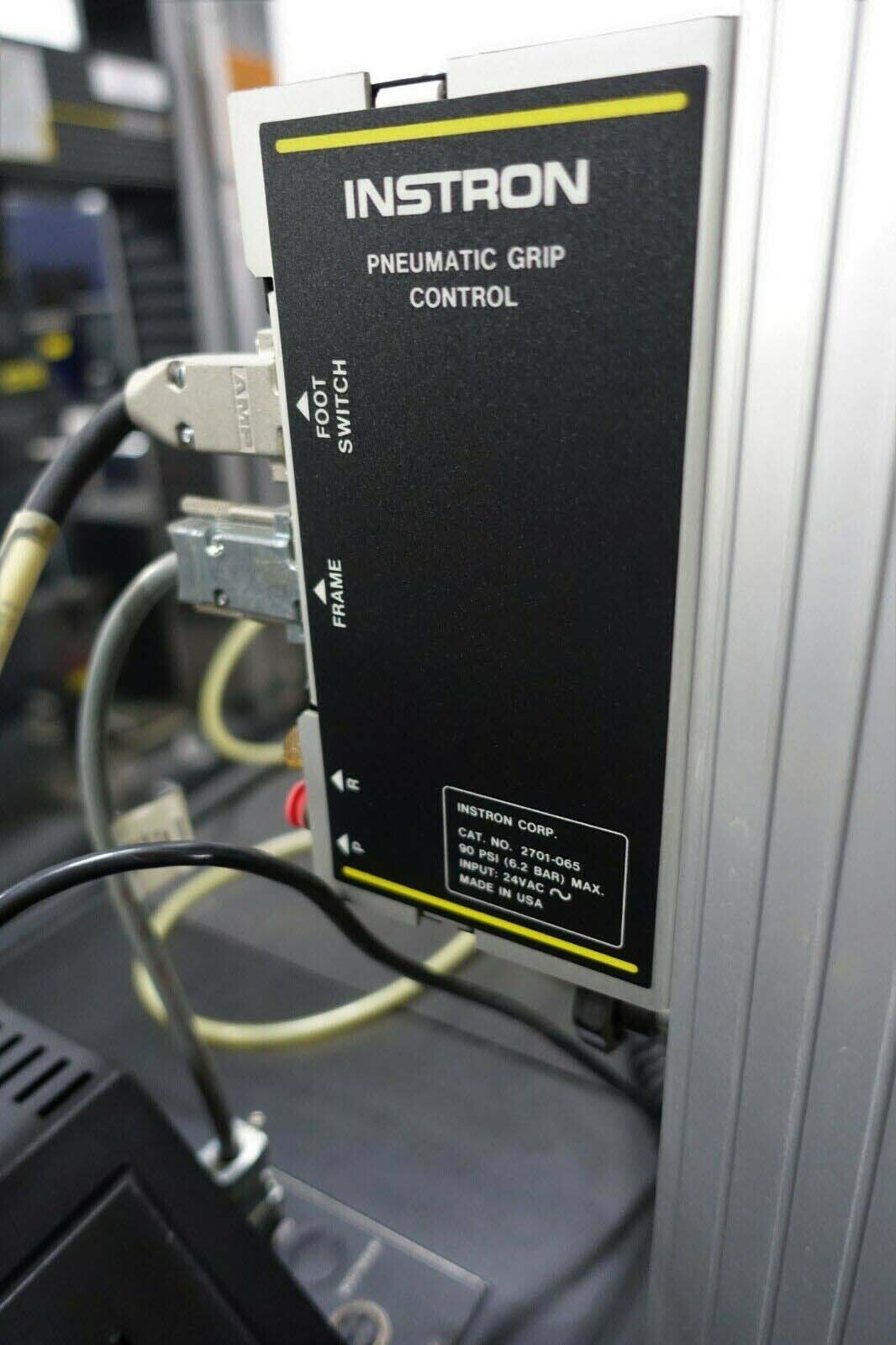

Automatic air control kit, P/N: 2701-065

With foot operated dual pedal switch

Strain gauge extensometer, P/N: 2630-102

Gauge, 10 mm

Max Strain: +/-50%

Load capacity: 2 kN (200 kgf / 450 lbf)

Maximum speed: 2500 mm/ min (100 in/min)

Minimum speed: 0.05 mm/min (0.002 in/min)

Maximum force at full speed: 1 kN (100 kgf / 225 lbf)

Maximum speed at full load: 1000 mm/min (40 in/min)

Return speed: 2500 mm/min (100 in/min)

Crosshead speed accuracy: ± 0.1% at steady state

Position repeatability: ± 0.015 mm (0.0006 in)

Acceleration time: 276 ms

Load measurement accuracy: ± 0.4% of Reading down to 1 / 100

Load cell capacity: ± 0.5% of Reading down to 1 / 250

Strain measurement accuracy: ± 0.5% of Reading down to 1 / 50

With ASTM E83 Class B / Class 0.5 extensometer

Crosshead position control resolution: 0.236 µm

Emergency stop time: 100 ms

Testing type:

Tension

Compression

Zero operation

Limited cyclic tester.

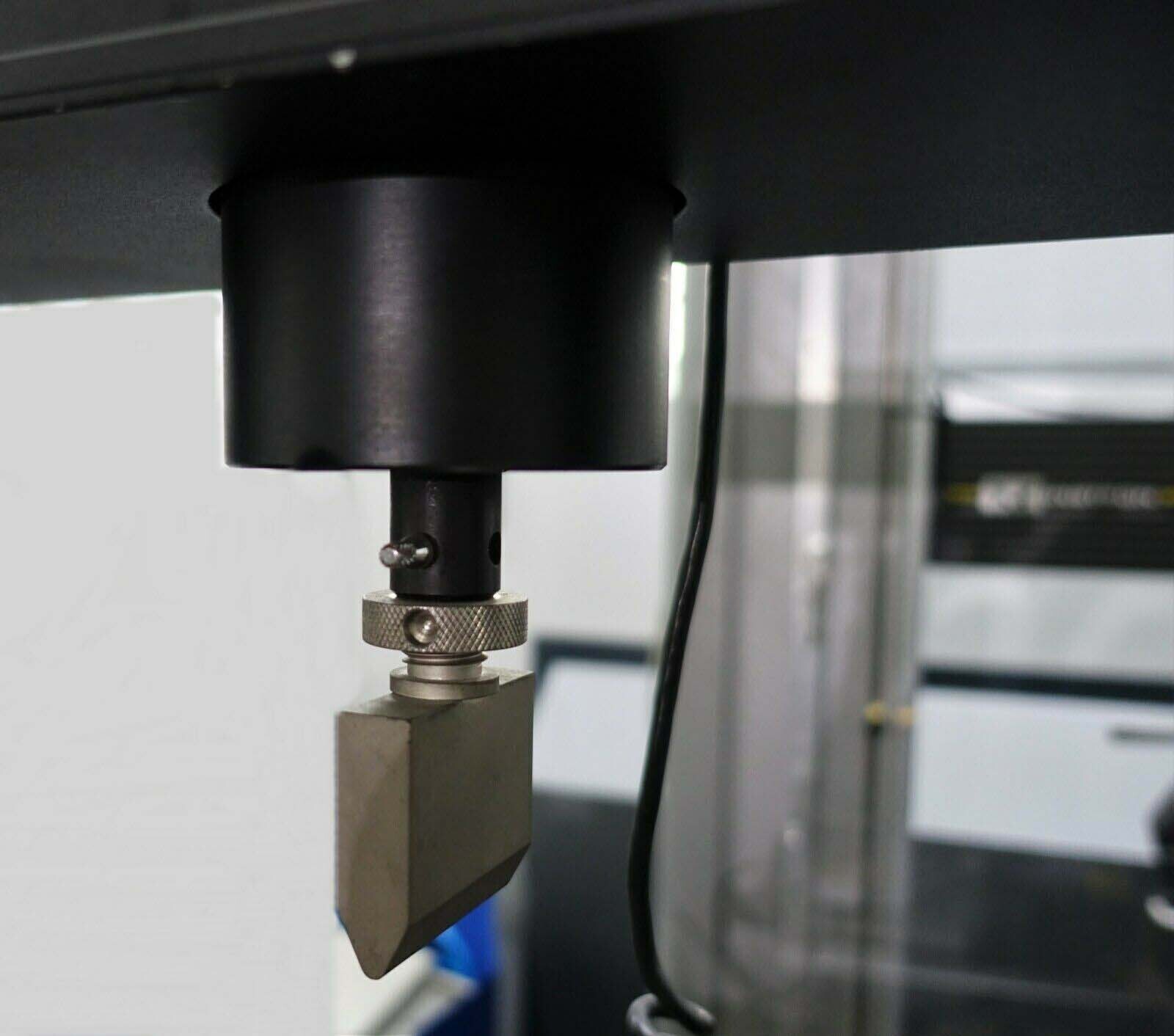

INSTRON 5564 materials testing equipment is an industry-leading laboratory equipment and accessory developed to carry out axial, torsion, tension, and compression testing of a variety of materials - steels, plastics, composites, films, rubbers, and more. This system offers a range of features and accessories that make it extremely versatile, allowing you to painlessly prepare samples, perform tests, and record results with accuracy and precision. To efficiently perform testing, 5564 unit includes a comprehensive package of components that enable accurate test preparation, sample loading and alignment, and measurement of parameters. The centerpiece of the machine is its high-capacity, stiff-frame, rigid-beam load frame design, which ensures precise alignment and accuracy of the specimen during loading. The load frame comes with an adjustable-height testing table and a choice of loads that can be adjusted easily to match the desired application. With its array of digital controls, INSTRON 5564 tool allows you to accurately set the parameters for any type of load application. The modular design of 5564 asset allows you to adapt the model to your specific testing requirements. By selecting from a wide range of available accessories, you are able to customize the equipment to perform a variety tests such as compression, flexure, and tension. Options for a wide range of actuators, load cells, data acquisition systems, displacement encoders, force transducers, and hydraulic components can be integrated into the system. INSTRON 5564 unit also allows for a range of interface options such as multiple communication ports, axes controllers, and vision systems. 5564 machine also includes a user-friendly Windows-based software package that simplifies data acquisition and analysis. This package enables you to record data in a range of formats such as tables and graphs, as well as allowing you to store, compare and analyze test results. The software also provides intuitive graphics that help you visualize your data, which allows you to identify trends and discrepancies. The software can also be configured to send test results directly to a printer, saving time and cost. Overall, INSTRON 5564 materials testing tool is an industry-leading material testing asset that offers tremendous versatility and robust performance. With its comprehensive package of components and easy-to-use software package, 5564 model is an ideal solution for accurate and precise testing.

There are no reviews yet