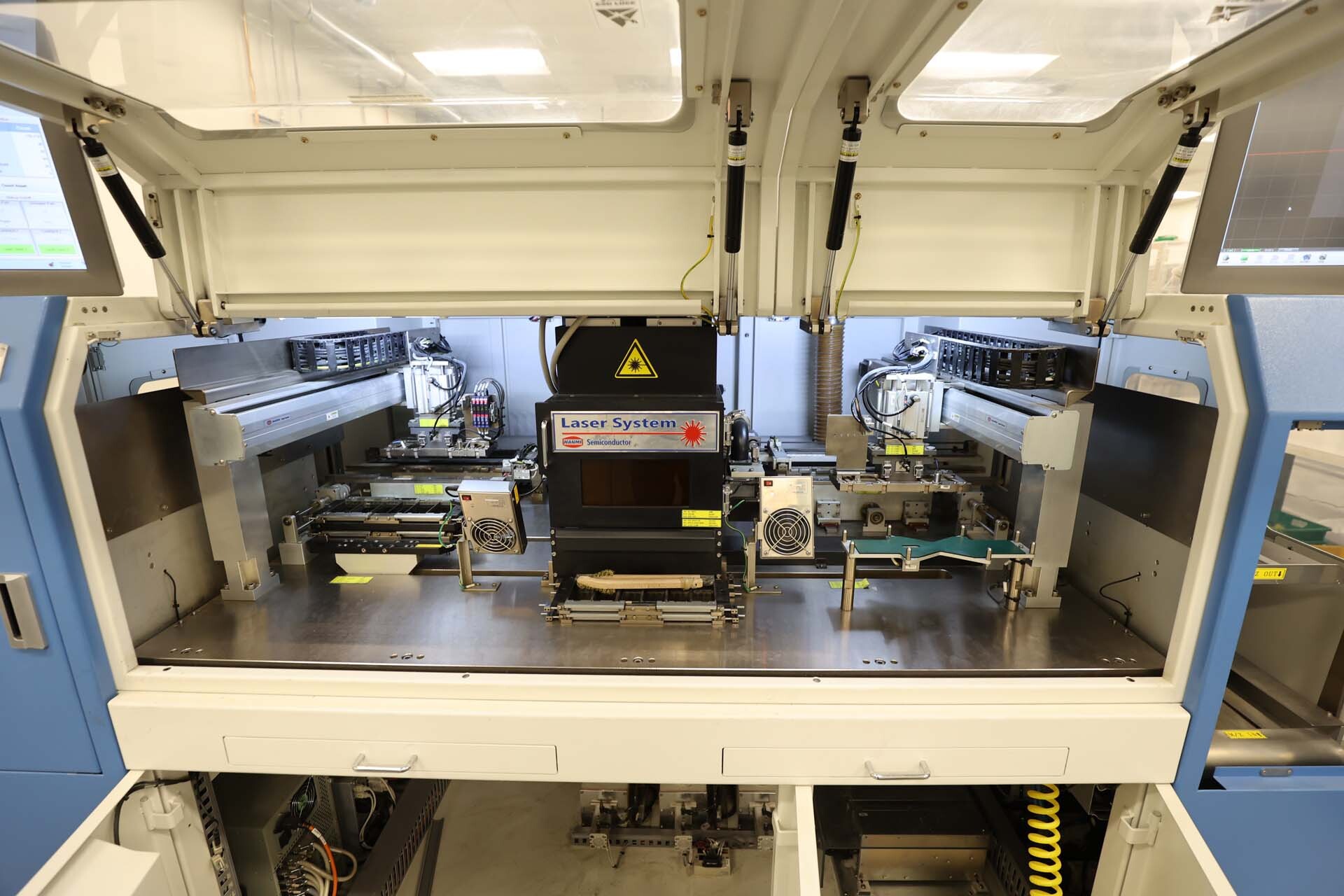

Used HANMI Deflash 2000 #293669779 for sale

URL successfully copied!

Tap to zoom

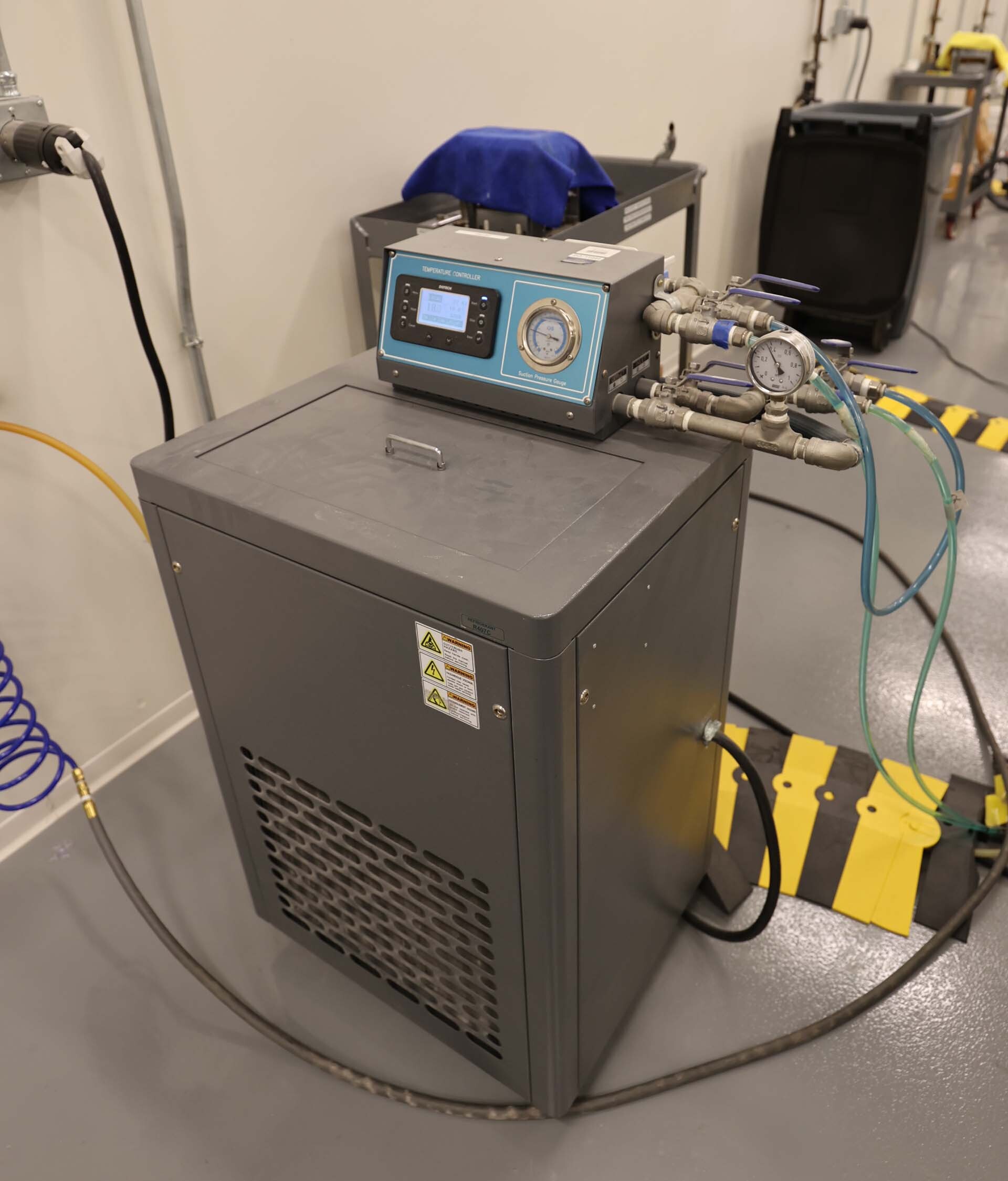

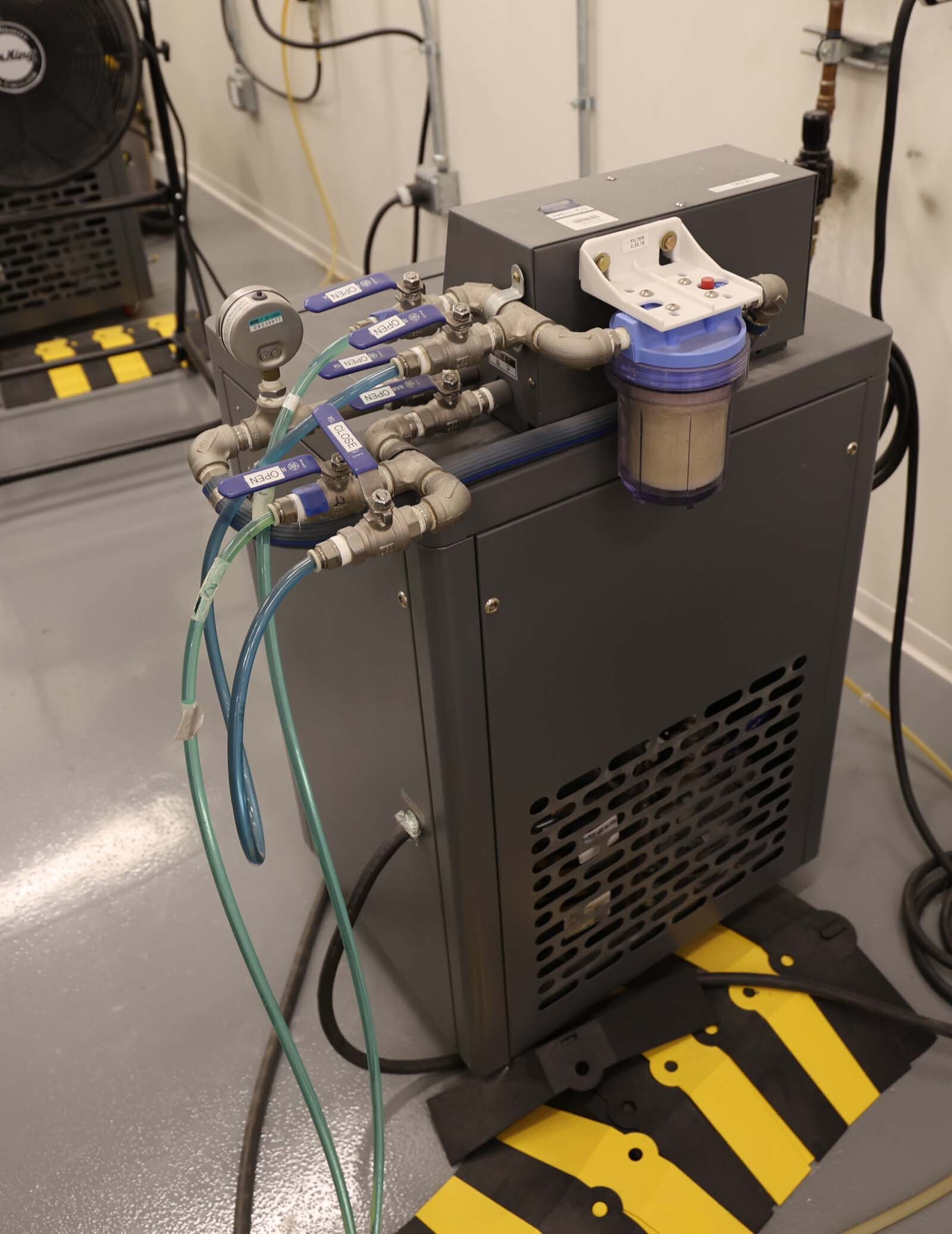

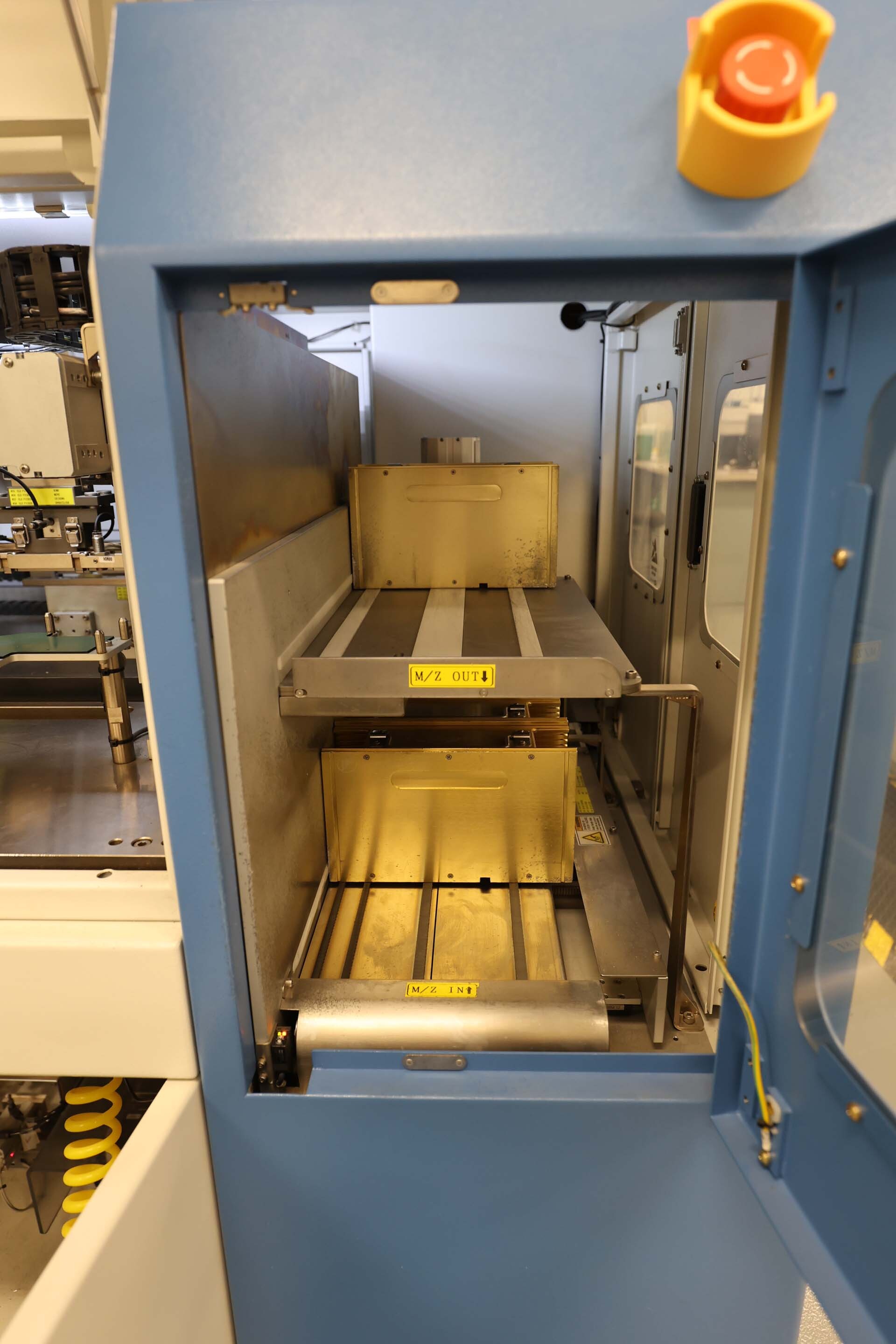

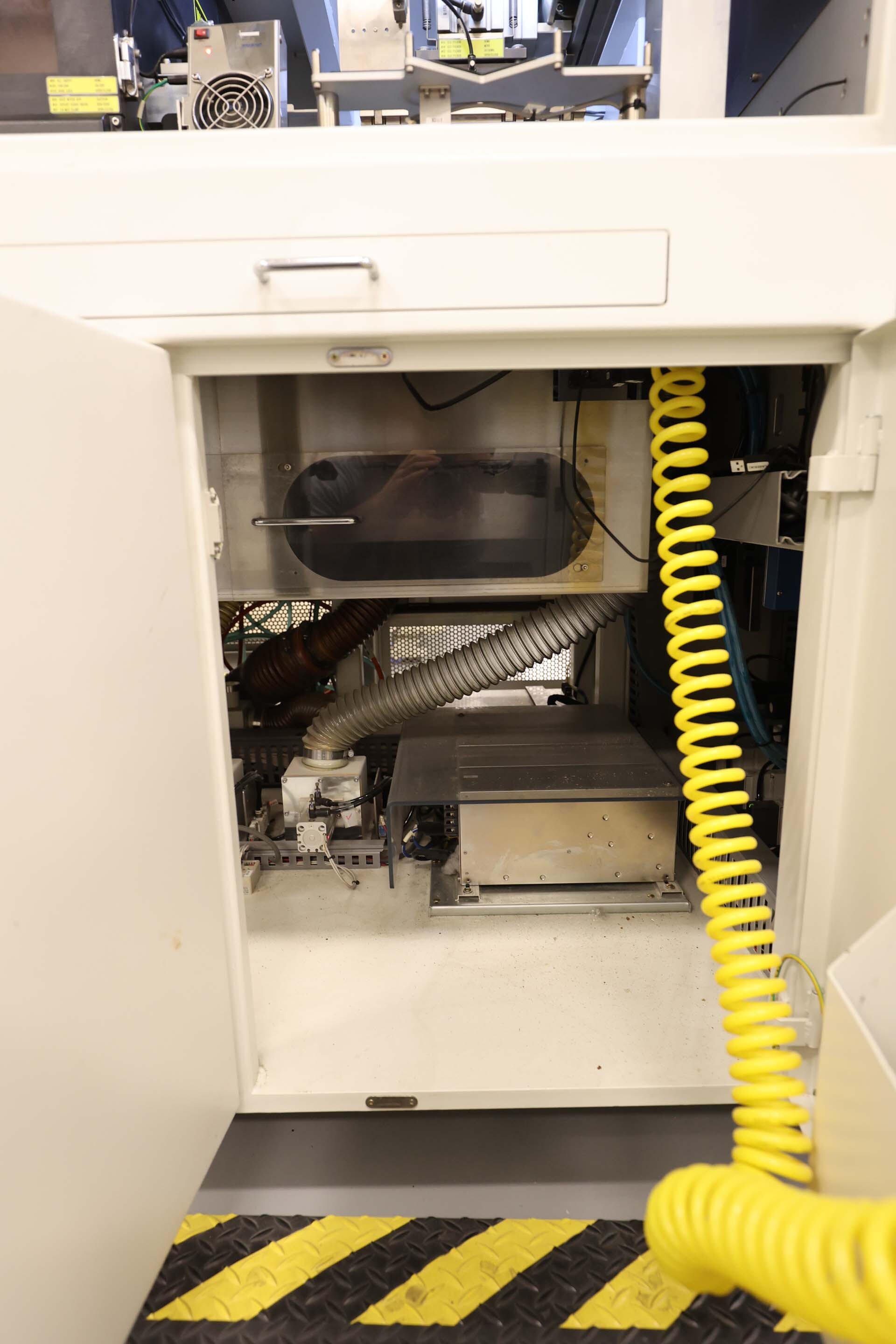

HANMI Deflash 2000 is a laser-based, optical equipment for deflashing, or smoothing, the surface of molded plastic products. Deflash 2000 is an automated system that requires minimal operator intervention and runs continuously at high throughput rates without human interaction. The laser ablation process removes flash or burrs from injection and blow molded components without causing any thermal damage to the product itself. HANMI Deflash 2000 consists of three major parts: a laser module, a scanner unit, and a product handling unit. The laser module is the heart of the machine, and performs the actual material processing. It contains a highly focused Nd-YAG laser operating at a wavelength of 1.06 μm. This laser generates a narrow, intense beam that offers superior ablation power and improved process control. The laser is capable of removing burrs and flash to a depth of 0.1 mm without damaging the underlying material. The scanner unit is a high-speed, XYZ-stage, which is used to move the laser beam across the component's surface, according to a predefined path. As the scanner moves the laser beam, it changes its position in the x,y,z axes to ensure that the beam is correctly aimed and focused on the component during processing. It is equipped with advanced optical sensors that monitor the position of the laser and automatically adjust the focus of the beam to the optimal level. The scanner also incorporates a programmable motion controller, which makes it possible to scan complex product geometries with high accuracy and repeatability. The third major component of Deflash 2000 is the product handling tool. This consists of an automated conveyor mechanism that moves the components through the asset, as well as a safety enclosure to protect the operator from the laser beam. The conveyer is equipped with multiple positioning sensors which are used to identify the component's position and then control the speed of the conveyor to ensure that the laser beam is correctly aimed at the product's surface. In conclusion, HANMI Deflash 2000 is a laser-based, automated model for deflashing molded plastic components. Its Nd-YAG laser and XYZ-stage scanner enable it to quickly, accurately, and precisely remove burrs and flash from injection and blow molded parts without damaging the underlying material. Its automated conveyor mechanism and safety enclosure make it suitable for continuous operation in manufacturing environments.

There are no reviews yet