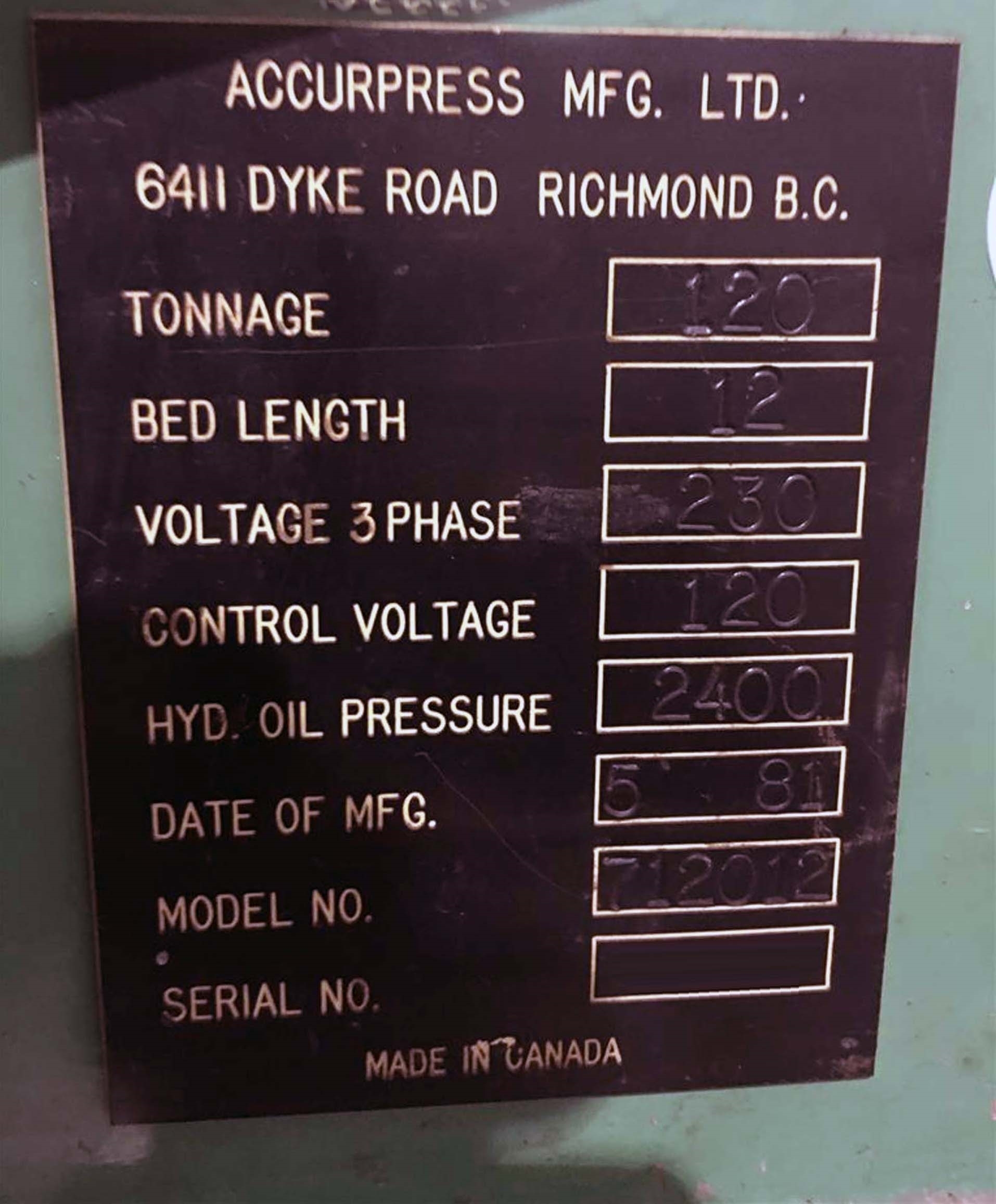

Used ACCURPRESS 712012 #9244556 for sale

URL successfully copied!

Tap to zoom

ID: 9244556

Vintage: 1981

Hydraulic press brake

Tonnage: 120 Tons

Bed length: 12 Feet

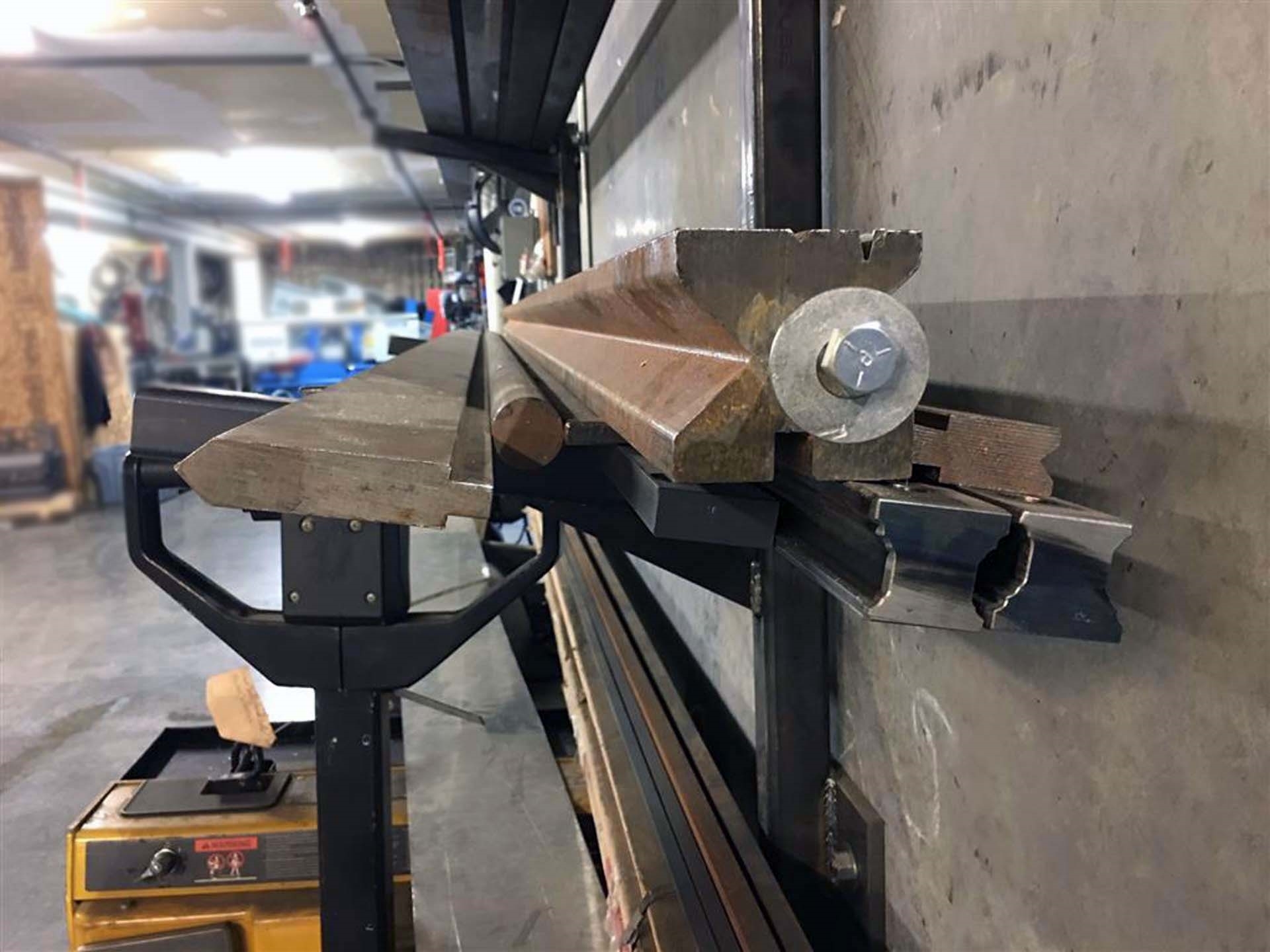

Equipped with:

Long: 12"

4 Way die approximate 3 3/16" square

V Opening: 2"

V Opening: 3/4"

Tongue for single V dies: 1/2"

Small V die & Acute die openings

Top punch: 1" Wide

Bottom single V die: 1/2" Opening

Power: 220V, 3 Phase, 60 Hz

1981 vintage.

ACCURPRESS 712012 is a pressbrake machine tool designed to form sheet metal components. It is equipped with an advanced CNC control equipment and servo motor feedback system for top-notch accuracy and repeatability as well as enhanced safety. This allows complex metal manufactoring with precision and efficiency. 712012 consists of a metal base and frame, and manual backgauge control, as well as the main control panel. The base and frame are made from premium-grade steel that is resistant to corrosion and wear, providing durability and extended longevity. The frame is designed to be rigid and sturdy with a high-performance guiding unit for the bending blades, allowing for tight bends and precise production. The CNC control machine of the pressbrake offers a number of features and capabilities, including digital readout of positions, a 3D simulation tool, automatic bend sequencing, and multiple language support. This allows the user to program complex metal parts quickly and accurately while automatically correcting any programming errors. The CNC also gives the user access to pre-programmed bends, ensuring accuracy and decreased machine-setup time. The servo motor feedback tool helps ensure the consistent accuracy of the pressbrake by providing feedback to the CNC asset in the form of signals. This feedback allows the machine to adjust the speed of the bending phenomenon or the dimensions of the bend (per the programmed instructions), in order to achieve the desired results. This reduces scrap and improves production speed. Safety is a very important part of using ACCURPRESS 712012. For example, the machine is designed with an IRIS light curtain model that detects any foreign objects entering the pressbrake's safe zone. If something is detected within the zone, the machine will shut down automatically. Additionally, the pressbrake has a handwheel so that the user can manually move the back gauge mid-operation. This allows the user to accurately adjust the shape or angle of the bend while the machine is still running safely. 712012 is the perfect machine for manufacturers looking for precision and efficiency when it comes to metal bending and forming. With its CNC control equipment, servo motor feedback, and array of safety features, ACCURPRESS 712012 offers the versatility and flexibility needed for proficient and efficient manufacturing.

There are no reviews yet