Used ACER 24160G #9113556 for sale

URL successfully copied!

Tap to zoom

ID: 9113556

Vintage: 1997

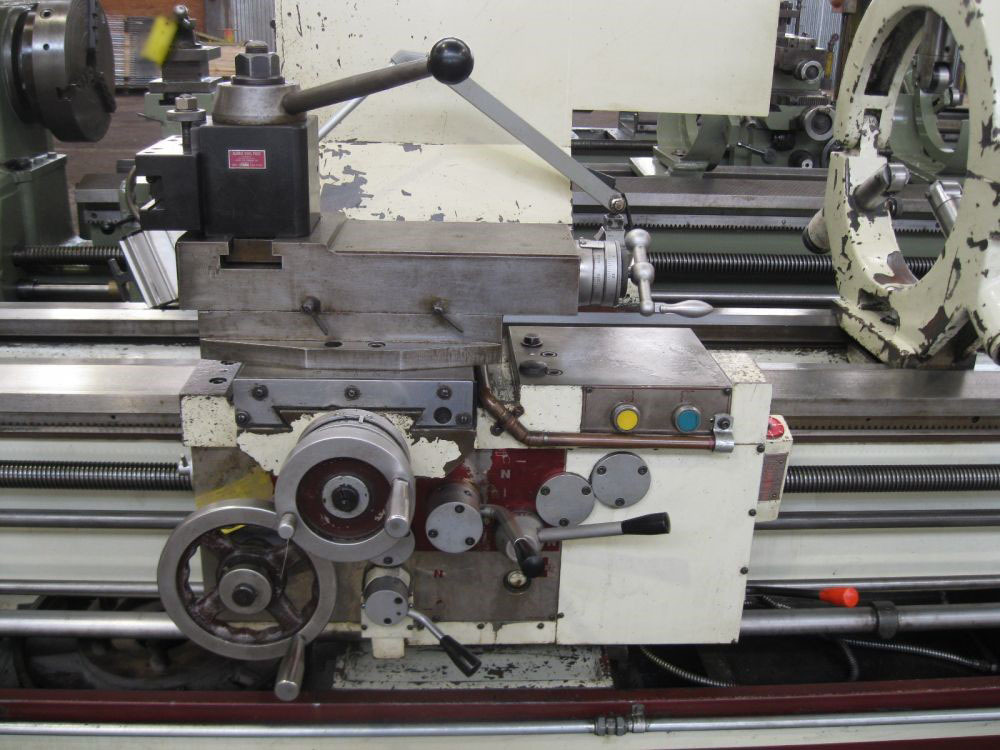

Gap-Bed Engine Lathe

20" 4-Jaw Chuck

22" Face Plate

(2) 15-1/2" Diameter Steady Rests

Sony Digital Readout

Aloris Tool Post

Threading Dial

Rapid Traverse to Carriage

Work Light

Foot Pedal Brake

Coolant System

Chip Pan Bed

Swing Over Bed: 23-5/8"

Swing Over 20-1/4" Gap: 32-1/4"

Swing Over Cross Slide: 15"

Distance Between Centers: 160"

Feeds – Longitudinal:0.0012" – 0.0287" / Rev.

- Cross: 0.0004" – 0.118" / Rev.

Threads – English:(45) 2 – 56 TPI

- Metric: (31) 0.5 – 14TPmm

Spindle Speeds: (12) 25 – 1200 RPM

Spindle Nose: DA – 11"

Spindle Hold Diameter: 4-1/8"

Motor: 15 HP 3/60

1997 vintage.

ACER 24160G is a sophisticated machine tool designed to meet the demanding needs of modern day production applications. It is a CNC controlled precision grinding center, capable of handling a broad range of grinding tasks with high levels of accuracy and repeatability. The machine has a 24-in swing and is equipped with three axes, and can be used with up to 8-in depth of cut. One of the main advantages of 24160G is its load and measuring capability. The machine has digital throughput with plunge feed rates and a 240-in/min. The machine is capable of working with a variety of materials, including ferrous and non-ferrous metals, plastics, and composite materials. In addition, ACER 24160G performs plunge feed grinding and micro-grinding as well as other operations. When it comes to the design of 24160G, the use of advanced machinery components is evident. The bed and spindle are constructed from hardened and ground cast iron. The guideways are box type and made from Meehanite, which is an engineered material known for its resistance to warping and wear. ACER 24160G offers the user a variety of programming systems. Tagged program cycles make the machine very efficient for the user. It is equipped with a RS232 interface and a variety of manual programming options. 24160G also comes with a touch screen monitor, allowing the user to view the programming and operation of the machine in a graphical manner. ACER 24160G features a number of safety features, as well. The machine is designed with a protective frame and splash guard to keep debris away from the working area. The grinding head features an emergency stop button that can be activated in the event of an unexpected or hazardous situation. Finally, the machine has a protective cover that prevents accidental damage to the control panel or the communications cable. All in all, 24160G is a highly accurate and reliable machine tool that is suited for a variety of different applications. Its ability to cut and shape materials with precision makes it a great choice for production shops that require high levels of accuracy and repeatability. Thanks to advanced programming and safety features, the machine reduces the risk of machine malfunctions and provides the user with increased safety during operation.

There are no reviews yet