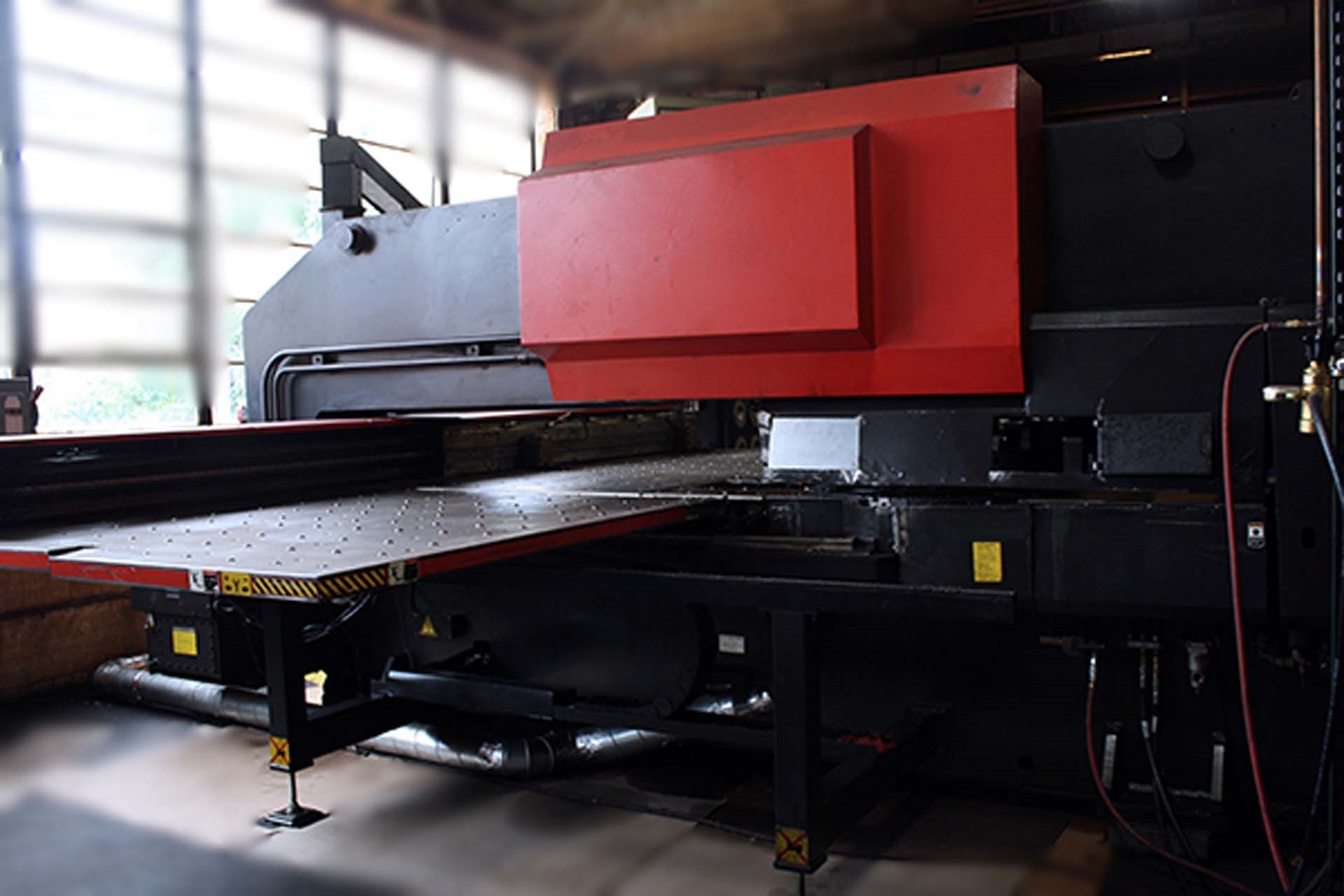

Used AMADA Apelio 5610 #9259854 for sale

URL successfully copied!

Tap to zoom

ID: 9259854

Vintage: 1996

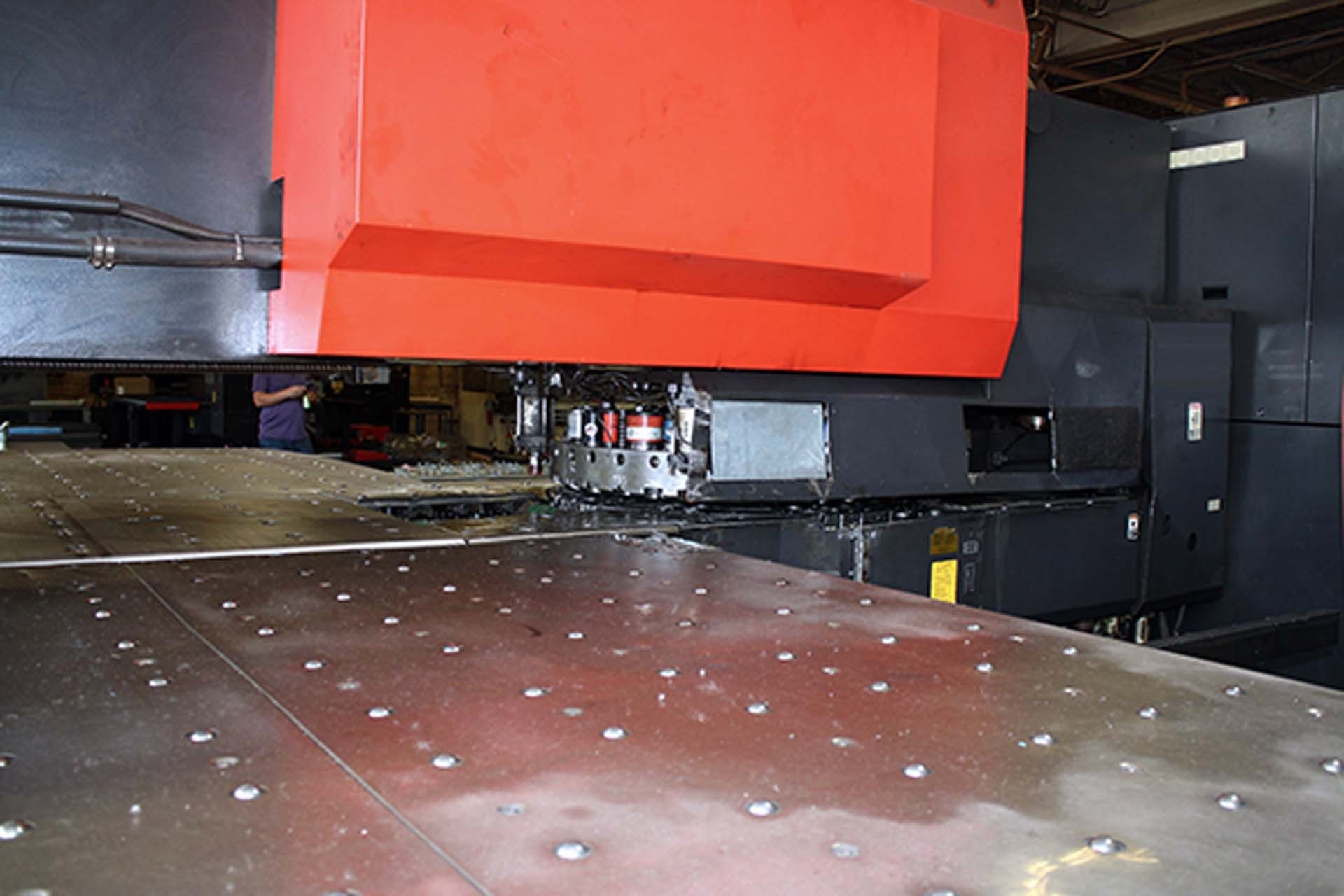

Turret punch

FANUC Control

Cooler

Conveyor parts

Sheet size: 60" x 100"

Thick capacity: 1/2"

1500 Watt

1996 vintage.

AMADA Apelio 5610 is a powerful and precise machine tool for efficient production of both ferrous and non-ferrous materials. It is a multi-axis CNC (Computer Numerically Controlled) turret punch press, specifically designed for shearing sheet metal out of the materials with very high accuracy. Apelio 5610 is equipped with an advanced and user-friendly AMNC control that provides a highly accurate punching process. It has a multi-tasking capability that enables multi-level operation of both punch and laser operations simultaneously, as well as punching and tapping. AMADA Apelio 5610 has a compact footprint, taking up minimal floor space despite its powerful performance capabilities. Thisturret punch press has an X-Y axis rapid traverse speed of 2,000mm per minute, and a maximum sheet size of 1550mm x 3,300mm. It can also handle sheet thicknesses of 0.8-6.35mm using AMADA Three-Damper System which eliminates vibration and leaves an exceptional edge quality. Apelio 5610 is designed to produce high-precision contours and intricate shapes with maximum accuracy. It is specifically designed to handle complex parts with multiple contours such as vehicle bumpers cladding, solar panel frames, cover panels, computer cases, and even medical devices. In addition, AMADA Apelio 5610 is equipped with an optional laser construction for laser cutting of small parts up to 6.35mm thick, including those of a more delicate nature. Laser cutting allows for higher speed and finer detail than traditional cutting methods. The combination of the laser and punch cutters provides a more efficient production process. Apelio 5610 ensures accuracy with a repeatability of +/- 0.05 mm in the X and Y axis. This machine tool can handle a wide variety of materials including steel, stainless steel, aluminum, brass, copper and other ferrous and non-ferrous materials. It is built with a specialized lubrication system that works on the entire machine, refrigerant circulation for the ball screws, as well as a motor-driven oil cooler. In addition, it has three punching stations which enable users to rapidly switch parts during production. AMADA Apelio 5610 has a high level of safety features, including a cross arm safety door, a hydraulic blade guard, an air blast for dust removal, and interlocking systems. An optional fully automated parts evacuation system simplifies parts handling and its high-pressure pump eliminates the need for manual cleaning of the machine. Overall, Apelio 5610 is a powerful, precise and reliable machine tool for working on a wide variety of ferrous and non-ferrous materials. Its high-precision production capabilities, advanced control features and automated production processes make it an excellent machine for industrial production.

There are no reviews yet