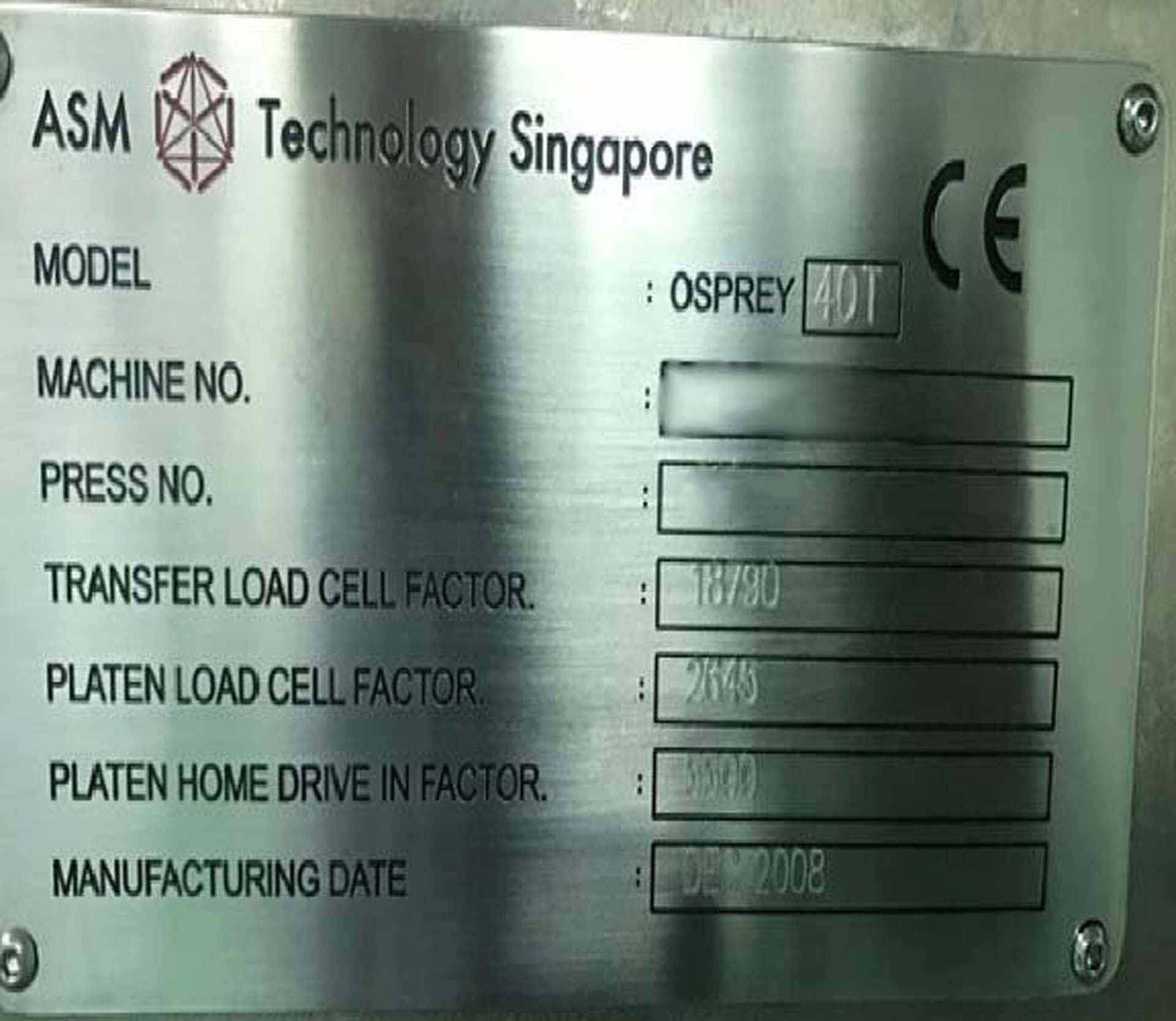

Used ASM Osprey 40T #9244953 for sale

URL successfully copied!

Tap to zoom

ID: 9244953

Vintage: 2008

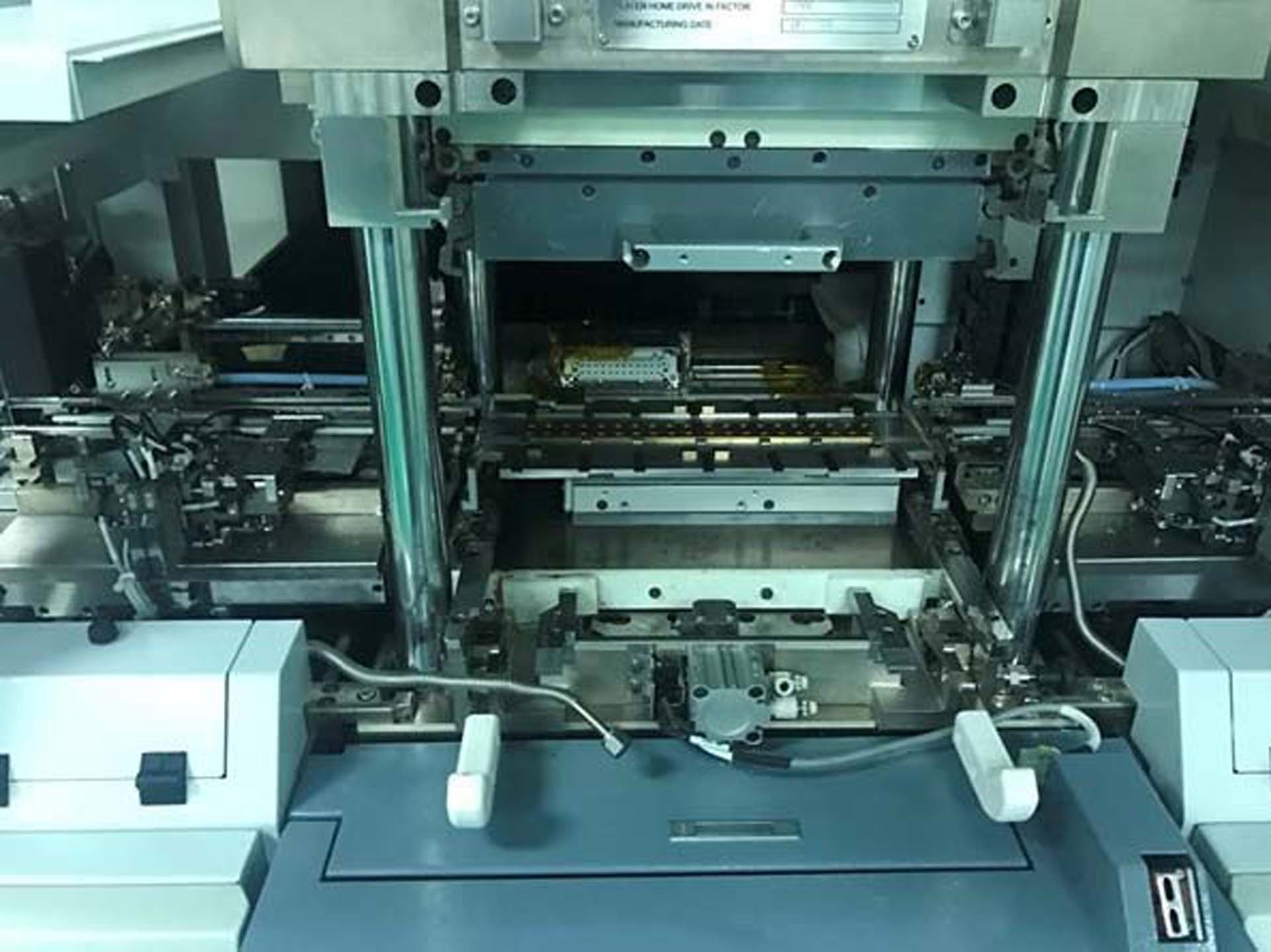

Auto molding system

Small lot high-mix molding platform for IC products

Ultra small footprint

Single 40T mechanical toggle press system

Standalone and with in-line configuration option

Handling leadless substrate size: 100 x 300 mm

2008 vintage.

ASM Osprey 40T is a high-performance machine tool designed for jig and tool production and metal component fabrication. It is composed of a powerful, reliable and long-lasting CNC controller with an easy-to-use interface as well as a X/Y/Z axis linear drive configuration and a high-accuracy cutting and machining head. The machine is capable of achieving precision machining of very small parts in multiple axes, as well as larger parts such as engine blocks. Osprey 40T is designed for high-speed functionality with an impressive 0.02mm positional accuracy, making it suitable for working with varied materials and cutting speeds. Its advanced CNC technology enables the machine to effectively utilize a wide range of cutting tools for further increased performance. Additionally, the machine includes proprietary software which enables the production of multiple parts at one time, allowing for a much faster production process. The machine tool also includes an additional safety feature which prevents the head from reaching a certain height and can be programmed to stop the machine if it strays from the designated program. Additionally, ASM Osprey 40T includes a unique water-bar system which helps to prevent contamination and improve the life of cutting tools. In terms of maintenance, Osprey 40T requires minimal attention and offers a long service life. Its easy to maintain and use and has been rigorously tested to ensure consistent and reliable operation. The machine is packed with a generous number of standard features such as onboard storage and easy tool change, double-arm work stands and an efficient filtration system. In summary, ASM Osprey 40T machine tool is designed to deliver time and labor-saving operations while also providing an exceptionally high level of accuracy and reliability. It is perfect for both short-run and long-run production of high-precision parts for a variety of applications. It is simple to use and operate, robust, and cost-effective, making it a great choice for any company.

There are no reviews yet