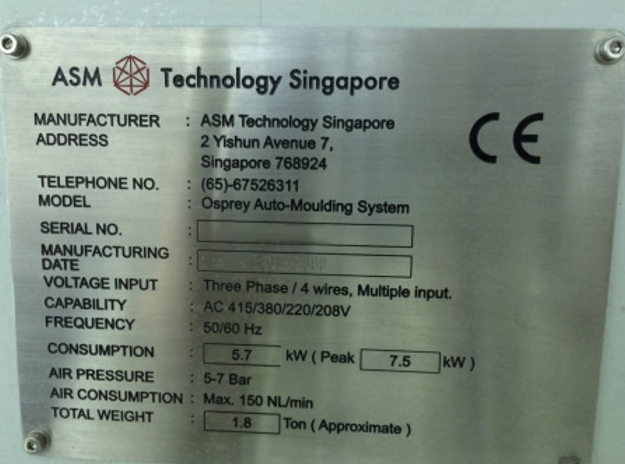

Used ASM OSPREY #9099430 for sale

URL successfully copied!

Tap to zoom

ASM OSPREY is a high-performance machine tool used to create parts with superior levels of accuracy, repeatability, and surface finish. It is suited for high-volume, high-precision production. OSPREY features a rigid cast iron base that houses two high-rigidity, dynamically balanced cast iron tables. The tables' high inertia support heavy work pieces with uniform force on all axes. They have toothed drives and trapezoidal threads to increase precision and repeatability. The design of ASM OSPREY also ensures very low thermal expansion so that the workpiece remains at the exact desired dimensions even during extended production runs. A large-diameter, motorized spindle also adds to the precision of OSPREY. The 1000-rpm motor utilizes cutting-edge spindle gap technology which allows it to move quickly and smoothly throughout its range while providing high vibration dampening. This allows manufacturing to take place with minimal interruption due to chatter or resonance. The machine also employs a precision contact-based temperature monitoring system that provides consistent thermal uniformity in the work area, further ensuring accuracy. It also features a closed-loop water cooling system that ensures consistent cooling for extended operation. ASM OSPREY also features a full range of fixtures and grippers for different parts. It can be configured with different tool carriers such as ATLA, TOM, and robotic tool changers which allow automated tool swapping. OSPREY can even be configured with a variety of software packages and data management systems to give users maximum flexibility and scalability. In summary, ASM OSPREY is a particularly high-precision machine tool which features a host of innovative and advanced features such as toothed drives and trapezoidal threads for increased accuracy, a spindle gap mechanism for reduce vibration, and a temperature monitoring system for consistent thermal uniformity. These features all combine to act as safeguards during long production runs to ensure parts with outstanding levels of accuracy, repeatability, and surface finish.

There are no reviews yet