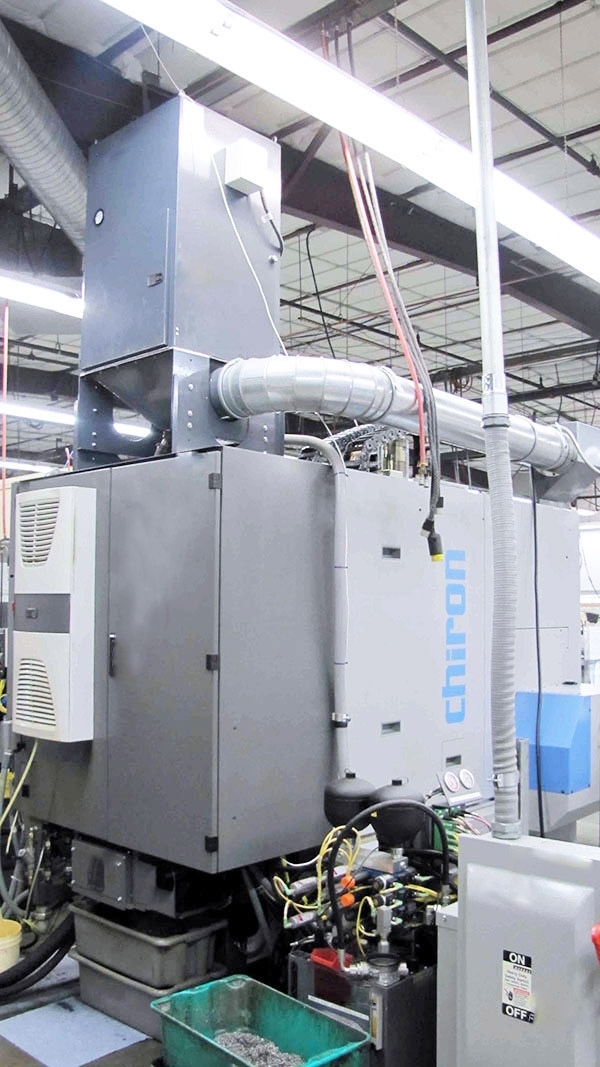

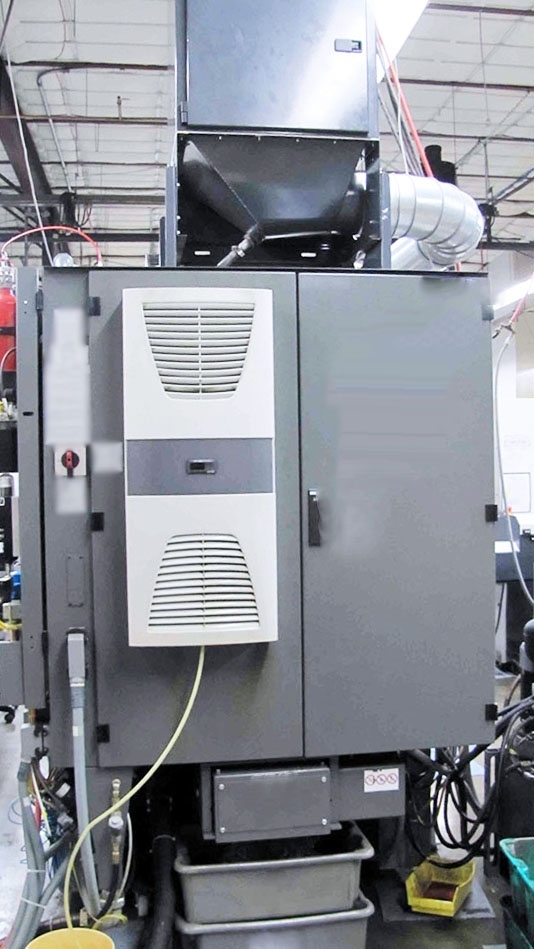

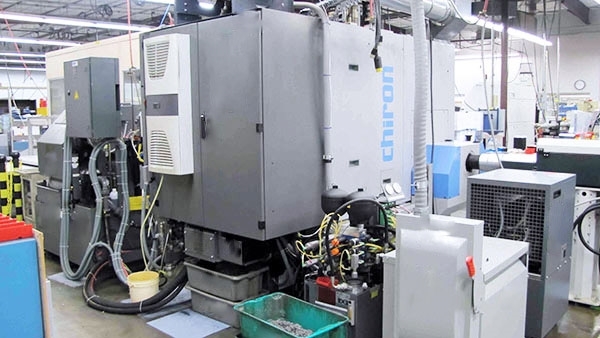

Used CHIRON FZ-12KS #9215397 for sale

URL successfully copied!

Tap to zoom

ID: 9215397

Vintage: 2010

Plus machining center

With Siemens 840 D control

Configurations:

Drilling capacity (steel 60): 0.98"

Milling capacity (steel 60): 7.32 ci/min

Tapping capacity: 0.787"

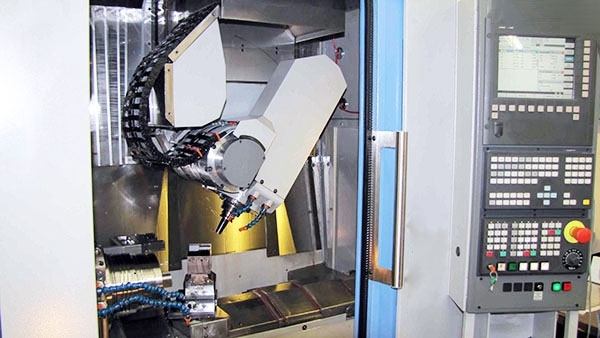

Number of axis:5

X - Axis travel: 21"

Y - Axis travel: 12.5"

Z - Axis travel: 14"

Spindle speed: 24,000 RPM

Tool changer type: 24 ATC

Tool taper: HSK-A 50

Maximum tool diameter: 2.3"

Tool length: 9.75"

Maximum tool weight: 6.6 LBS

Tool change time (approximately): 0.9 sec.

Chip-to-chip time (approximately): 2.4 sec.

Rapid traverse X/Y/Z: 246.063'/min

Includes:

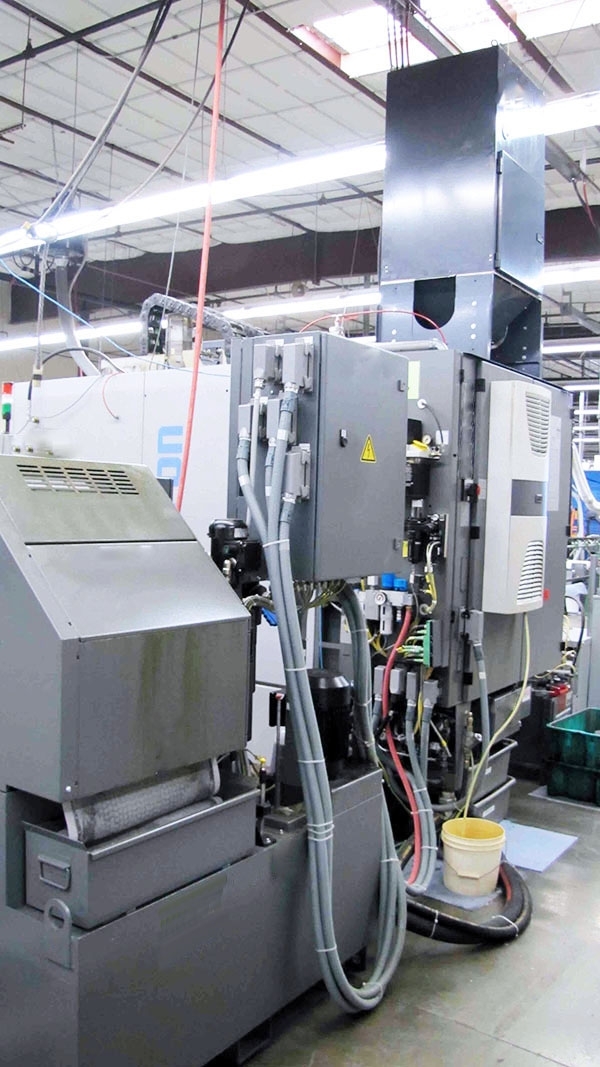

Chip conveyor

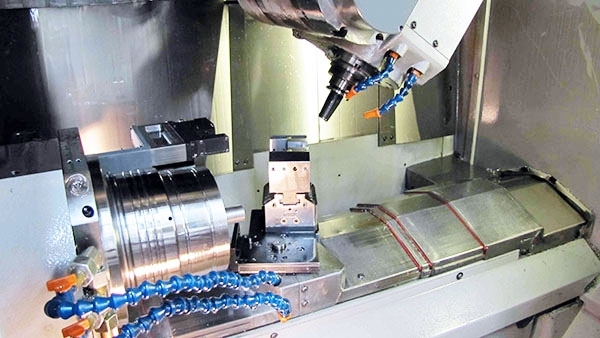

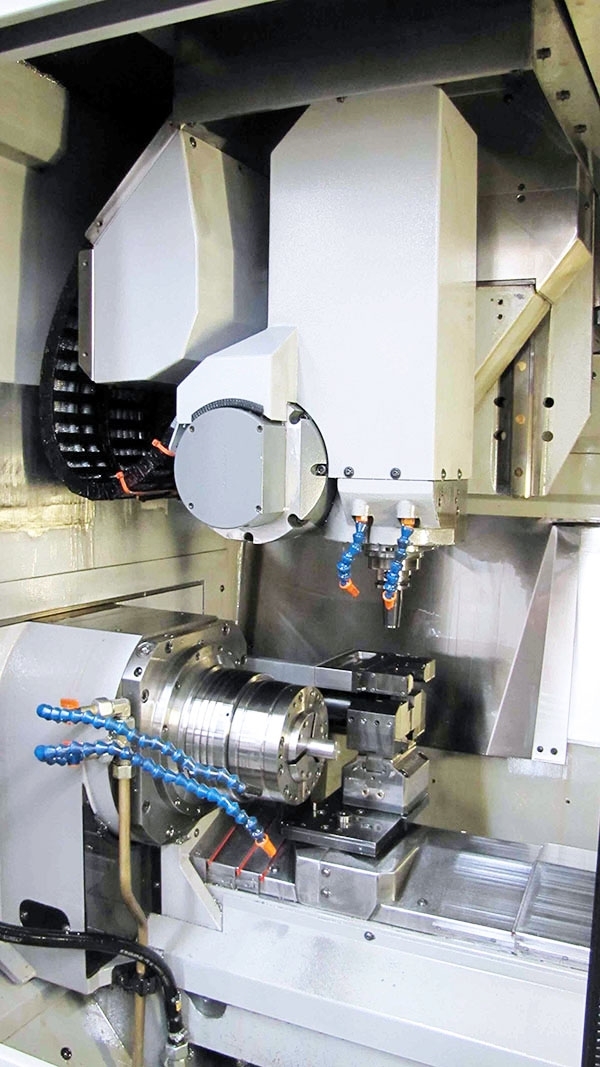

NC swivel head W/ HSK 50

48 tool position upgrade (47 pockets)

Coolant equipment KF 150/KFA 500

208VAC-480VAC transformer

Glass sales in all axes

Fixture flush 1 zone

Flow control switch (for fixture washing)

Automatic central lubrication

Preparation for mist collector and mist collector

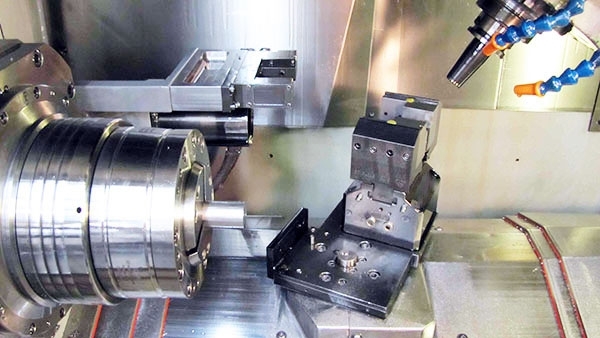

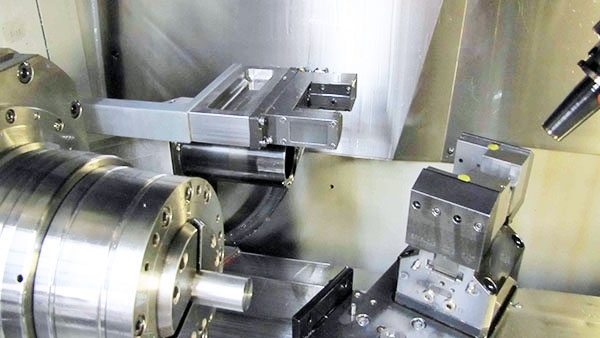

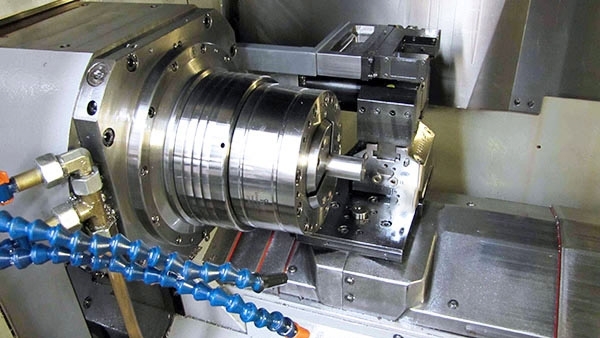

Technology for turning from bar 65mm diameter

Lathe spindle (65mm diameter 4500RPM)

NC turning unit with hydraulic clamp vice HZS 110-Z

Hydraulic unit for vice W/ clamping tools

Machine table W/ 2 mounting surfaces

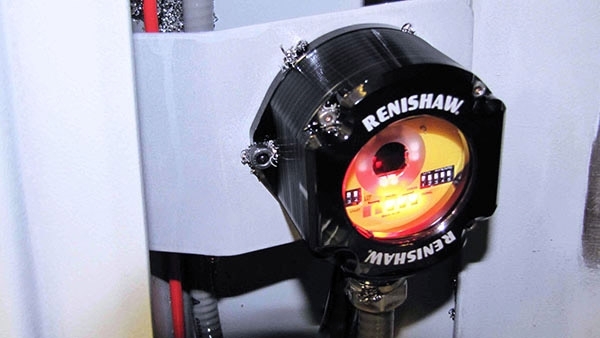

Renishaw probe package (OMP 40-2LS)

Torit mist control system

1000 PSI high pressure pump - knoll

Thru the tool coolant.

CHIRON FZ-12KS is a high-precision machine tool designed specifically for cutting and finishing metal parts. It has a host of features which enhance its accuracy and performance, making it suitable for a wide variety of machining operations. The machine features a three-phase (WYE and Delta) servo motor drive equipment that provides superior dynamics and greater output. The servo motors have advanced motion control algorithms that ensure precise and repeatable positioning. They also allow for increased acceleration and deceleration times, minimizing downtime and delays. The control system includes intuitive user display and controls, enabling manual and automatic operation of the machine. FZ-12KS is fitted with a high-speed spindle that provides fast and accurate cuts. The spindle is driven by a beltless direct-drive motor that offers a greater weight capacity and greater torque. This efficient drive unit eliminates the need for a gearbox for smooth and accurate cutting. The machine also features a high-precision linear guideway for superior accuracy and repeatability over long distances. With the help of an advanced detection machine, it is able to detect and compensate for any misalignment or distortion during operation. This ensures that all cuts are perfect and repeatable. CHIRON FZ-12KS also features a range of other features that make it a versatile and reliable industrial machine tool. These include an auto-adjusting angle of attack, which allows for the adjustment of the cutting angle without having to manually adjust the machine. It also features automatic tool change, with various cutting tools stored in the machine, which can be changed quickly and easily without interrupting the cutting process. The machine also includes an integrated safety tool and overload protection, as well as a rigid cast-iron construction for strength and longevity. It has also been designed with modular construction, making it easier to transport and store the machine. Overall, FZ-12KS is a highly-accurate and powerful machine tool that is suitable for a wide range of cutting and finishing operations. Its intuitive user interface, advanced motion control algorithms, and robust construction make it reliable and efficient in any machining application.

There are no reviews yet