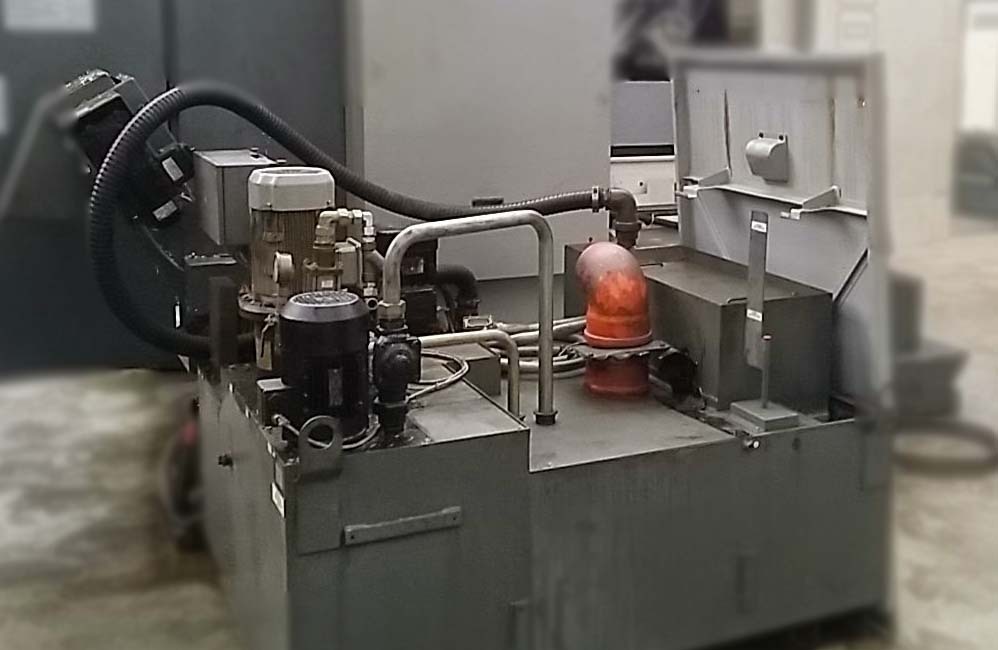

Used CHIRON FZ-15KS #9179205 for sale

URL successfully copied!

Tap to zoom

ID: 9179205

Vertical machining center

Single pallet

Acceleration: 1,2 g acceleration on Z axis, 1g on X and Y

60 meter rapids (2362 inch / min)

Spindle: 12000 rpm, 0-10000 rpm 1 second (great for drill+tap operations)

4th Axis peiseler

Coolant through spindle

Renishaw probe (Broken tool detector)

2.5 sec chip-to-chip toolchange

(36) Tools.

CHIRON FZ-15KS is a high-performance vertical machining center equipped with a cutting range of up to 15,000 rpm. It is designed for high-speed, high-precision machining with the ability to complete complex 3-axis machining processes in a single set-up. Its all-round configuration with a powerful radial cutting force and rapid feed rate make it ideal for a variety of tooling and machining needs. The cutting spindle of FZ-15KS is capable of rotating up to 16,000 rpm, and features an optimized internal cooling equipment for efficient heat dissipation. It also comes equipped with a hydraulic spindle clamping system for improved rigidity and accuracy. This ensures that the cutting tool remains securely held under both static and dynamic loads. CHIRON FZ-15KS is powered by an asynchronous motor which delivers smooth torque, even at high speeds. It has an APT Plus servo drive unit for maximum rigidity and accuracy in the machining process. This drive machine offers a wide range of motion profiles and interpolation modes. Together with its 'continuous path' tool, it enables highly accurate and consistent results in complex 3-axis machining processes. FZ-15KS comes with a range of optional tools and accessories, such as a 4th axis rotary table, a feed unit, and an extension unit, to give even more flexibility. The optional 4th axis rotary table enables simultaneous rotation in 4-axes, allowing for intricate parts production. The feed unit provides tool settings, positioning accuracy, and process data monitoring. And the extension unit provides more spindle assembly space to accommodate larger parts. CHIRON FZ-15KS has a highly rigid and stiff casting frame which gives superior vibration damping performance. Together with its hardened guide ways, this facilitates precision machining of even complex shapes. For improved cutting accuracy and surface finish, it has a Heidenhain iTNC530 CNC control with integrated CNC 4th axis technology. Within the Heidenhain controller, it is possible to program various machining tasks including contouring, drilling, threading, and surface roughing. Overall, FZ-15KS is a reliable and highly accurate machine tool. It offers maximum flexibility in terms of its cutting range, rigidity, and accuracy. With its variety of optional tools and accessories, it can easily be tailored to individual machining requirements. An ideal choice for high-precision operations and complex shape production.

There are no reviews yet