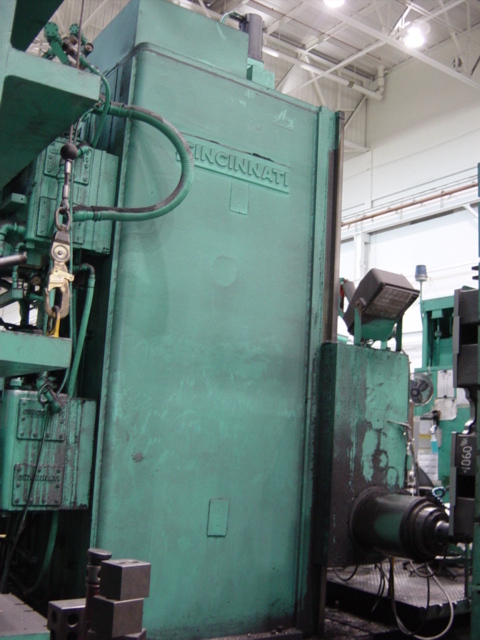

Used CINCINNATI Bar Type #137826 for sale

URL successfully copied!

Tap to zoom

ID: 137826

Horizontal milling machine

Bar type

Fixed Work, Traveling Spindle

The Spindle assembly consists of a 6” diameter bar coaxial with a 12” outer Spindle inside a 14” Quill

The outer Spindle moves with the Quill in the “Z” axis

The Bar travels independently of the Quill supported by sleeve bearings, and also moves in the “Z” axis

X (Horizontal) Axis travel = 312” (26') (Plus 2” overtravel at each end)

Y (Vertical) Axis travel = 84” (7') (Plus 2” overtravel at each end)

Z Axis travel = 36” (3') (Plus 1” overtravel at each end)

Feed rates:

Manual Mode – X,Y,Z, = 0.5-150 I.P.M.

Numerical Control Mode – X,Y,Z, = 0 -150 I.P.M.

Slew Mode – X,Y,Z, = 150 I.P.M.

Spindle Speed 18 – 1800 R.P.M.

Bar Nose Dia = 6”

Bar Travel (Z Axis) 36”

Intermediate Spindle Dia. = 11.906”

Quill Dia = 16.500”

Quill Travel (Z Axis) = 36”

Ranges:

Intermediate Spindle face to Carrier face = 1.500” – 37.500”

Bar face to Carrier face = 5” – 41”

Bar centerline to top of work table = Max 78”

Bar face (retracted) to edge of work table = Min 7”

Work mount angle plates:

9’ high x 9’ wide vertical face with T-Slots x 4’ deep base plate

6’ high x 6’ wide vertical face with T-Slots x 4’ deep base plate

Work Tables:

8’ Deep x 10’ wide T-slotted – pit mounted

6’ Deep x 10’ wide T-slotted on 8’ x 10’ base – surface mounted

Numerical Control:

Delta Tau retrofit 1995 PMAC Operating System with Paradym 3.1 Industrial Control Software.

De-installed 2001.

CINCINNATI Bar Type Machine Tool is a unique, high-power and flexible machine tool that is capable of accommodating and machining complex parts. It is comprised of solid cast iron frames that provide the highest accuracy and rigidity, making it ideal for precision manufacturing, especially for intricate components for a range of industries. Bar Type uses an intelligent spindle base that uses advanced, servo-driven technology to provide superior positioning accuracy and control, ensuring maximum production efficiency. This spindle base is capable of operating at high operating speeds, achieving up to 8500 RPM, which allows the machine to create precision parts quickly and accurately. CINCINNATI Bar Type is also equipped with dual gear systems, which provide a high load capacity while maintaining low noise levels. The machine's design also features extensive anti-vibration features that offer a smoother and quieter working environment, allowing for greater output. To further optimize accuracy, Bar Type comes with an automatic lubrication system that applies lubricant to all motion parts throughout operation, leading to smoother, more efficient machining and longer running tool life. The machine is also designed with a power failure detection system and other safety-related features which helps protect against potential accidents. Furthermore, CINCINNATI Bar Type is highly modular and can be customized to meet specific needs. It is compatible with an array of work-holding devices, cutting heads, and automation systems and is compatible with both conventional and high-speed/oxide-dispensing cutting systems. It also has a wide range of tooling options available, including milling, drilling, reaming, tapping, and grinding tools, giving Bar Type the versatility to handle a wide range of machining purposes. CINCINNATI Bar Type Machine Tool is an ideal investment for a variety of industries due to its superior accuracy, flexibility, and safety features. It is the perfect solution for industries looking for high-powered precision machining solutions, and can maximize productivity while decreasing the workload.

There are no reviews yet