Used CINCINNATI EA #9106119 for sale

URL successfully copied!

Tap to zoom

ID: 9106119

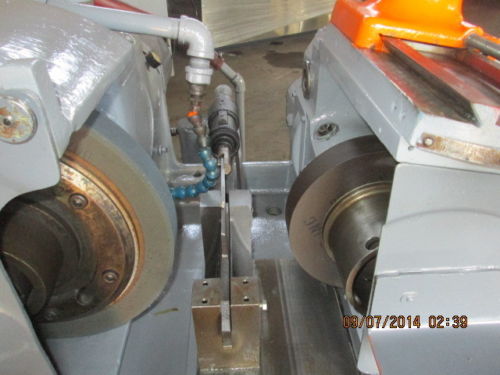

Centerless grinder

Capacity (Standard Work Rest): 1/16" to 3-1/2"

Wheel Size (Grinding): 20" x 8" x 12"

Grinding Wheel Drive Motor: 15 HP

Regulating Wheel Drive Motor: 1-1/2 HP

Electrics: 220-440V, 3 Phase, 60Hz

Wired for 440 Volt

Infeed, mechanical work rest

Hand operated infeed of grinding wheel slide

Hydraulic dresser on grinding and regulating wheel

Coolant and Tank

Currently setup for thru feed work.

CINCINNATI EA machines are high-precision CNC machining centers that are designed for a variety of machining applications. EA is built with an advanced three-axis spindle control equipment that allows for tight dimensional accuracy and smooth part feeds. This machine is commonly used in the automotive and aerospace industries for a variety of machining operations such as milling, drilling, boring, and tapping. This advanced machine tool technology from CINCINNATI combines a CNC multi-axis control system with a rigid machine frame. This design delivers improved cutting accuracy and improved productivity. CINCINNATI EA series takes machining to a higher level with its robust design, allowing for continuous and unattended machining operations. EA has a maximum spindle speed of 6500rpm with direct-drive servo motors and high-torque spindle motors. Its optional 32-tool carousel magazine and optional coolant makes high-speed machining operations easier and increases part-to-part interchangeability. CINCINNATI EA series machine also has a CNC-controlled X-axis linear guideway available with the optional Kinematic Coupling Unit, enabling faster travel speed and a maximum 5000 pulse/min. This machine delivers smooth, accurate and repeatable accuracy and precision even at a faster speed. The control unit of this CINCINNATI machining center is the latest FANUC 0i-TD control tool with a 19-inch color LCD display, which makes the machine reliable and user-friendly when it comes to controlling operations. This sophisticated machine also has a color touch-screen graphic user interface with LCD instruction, making it easier for operators to program the tools. The machine has a variety of safety features such as CE protection covers in the work area, secure and dry coolant, automatic tool locker, and a two-hand control signal function. This machine also comes with Automatic Parts Organizer Asset (APOS) to enable efficient inventory management. Overall, EA series is a high precision CNC machining center that provides users with smooth, accurate and repeatable precision for a variety of machining applications. It features an advanced control unit, optional coolant, robust machine frame and a variety of safety features, delivering reliable and precise results for guaranteed customer satisfaction.

There are no reviews yet