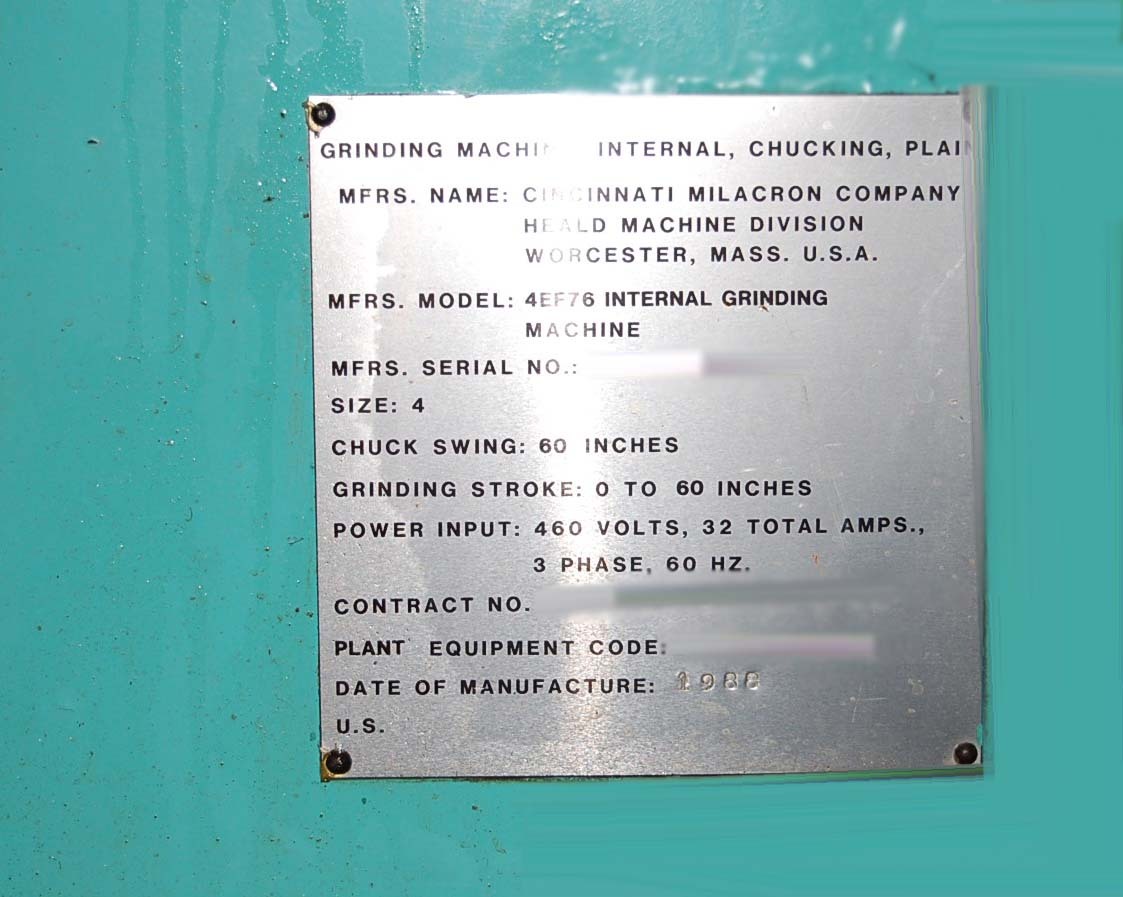

Used CINCINNATI MILACRON 4EF76 #9157290 for sale

URL successfully copied!

Tap to zoom

ID: 9157290

Vintage: 1988

Heald internal grinder

Maximum swing: 60”

Maximum depth of hole: 60”

Cross travel: 8”

Longest part: 82”

Grinding spindle motor: 15 HP

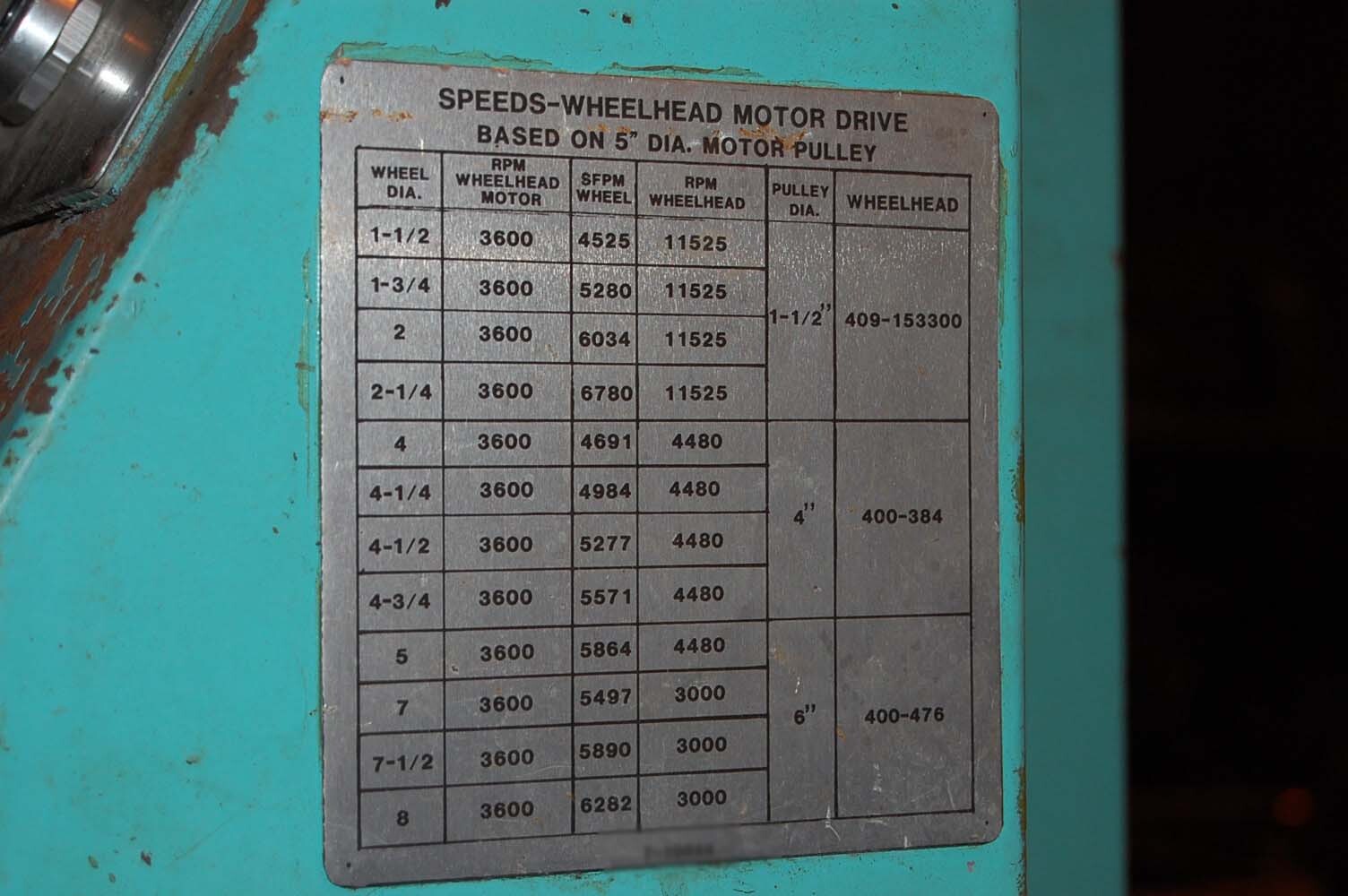

Maximum grinding spindle Rpm: 4500

Work head Rpm: 875

Steady rest: 24”

(3) Point

Face plate: 48”

Programmable grind

Bore

Plunge

Face

Dressing cycle

(2) Axis DRC digital readout

Pick feed

Spark out

(2) Red head spindles:

3.5” x 32”

5.5” x 48”

Coolant with magnetic filtration system

1988 vintage.

CINCINNATI MILACRON 4EF76 is a robust wafer grinding, lapping and polishing equipment, ideal for large-scale wafer processing. It is specifically designed for production of photovoltaic solar cells and other types of silicon wafers. The system is comprised of an operating platform that houses four separate, independent, precision grinding, lapping and polishing units, capable of achieving up to 15 mO/cm of surface electrical resistance, an integrated loading and unloading unit for automated production capabilities, and integrated process control and monitoring equipment. 4EF76 utilizes special grinding wheels and polishing pads to achieve a surface roughness of nearly one nanometre, suitable for fine-tolerance and precision machining. It features integrated process control and monitoring systems which allow for automated, accurate, and repeatable surface characteristics. The machine also includes wear and corrosion sensors which monitor the grinding and lapping process, providing consistent power and depth of cut. CINCINNATI MILACRON 4EF76 is capable of dealing with up to 75 wafers at a time, and can process a new wafer in as little as 8 seconds. It comes equipped with a tool for measuring and controlling the mechanical grinding and lapping force, the amount of pressure used to machine the wafer; a asset for testing the electrical properties of the wafer, such as surface electrical resistance, sheet resistance, and other characteristics; and a model for measuring the surface roughness and wafer edge detail of the finished part. 4EF76 is designed for ease of use and maintenance. It is engineered with corrosion resistant, vapor and dust proof materials, and has an onboard fire suppression equipment for added safety. The system has a fast recovery time and a low thermal drift rate, making it highly reliable and ideal for continuous operation. CINCINNATI MILACRON 4EF76 is the perfect unit for producing large-scale, high-precision wafers in manufacturing facilities. It is capable of delivering consistent, accurate and repeatable results in a fast and efficient manner. Its corrosion-resistant materials and integrated safety measures make it durable and user-friendly, and its automated, accurate, and repeatable process control systems give it the edge in faster, more efficient production.

There are no reviews yet