Used DECKEL / MAHO DMU-35M #9218485 for sale

URL successfully copied!

Tap to zoom

ID: 9218485

Vintage: 2000

CNC Machining center

5-Axis (3 + 2)

X-Travel: 350 mm

Y-Travel: 240 mm

Z-Travel: 340 mm

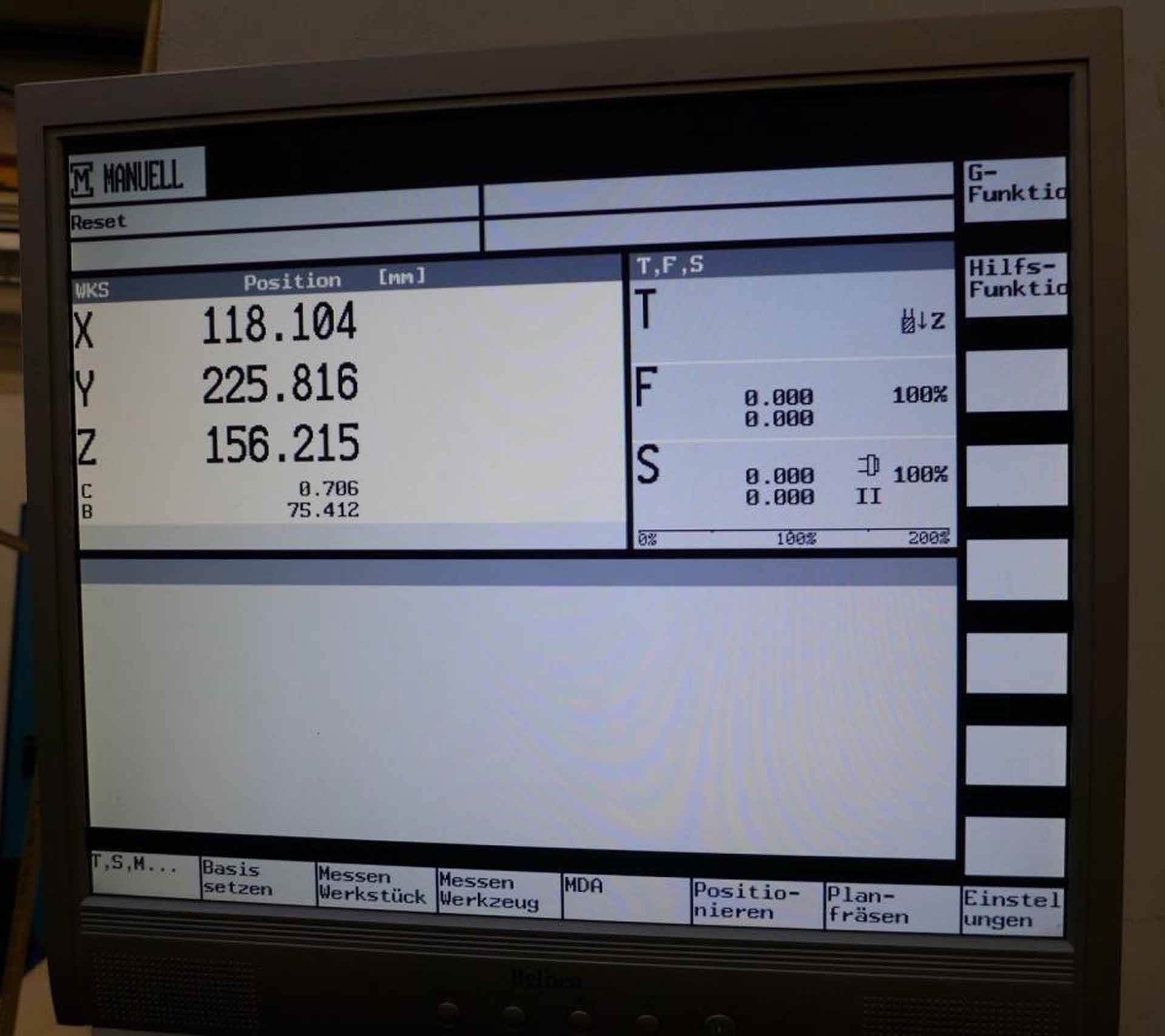

Control: SIEMENS / SINUMERIK 810D

Spindle hours: 18,000

Chip tray

Elektr hand wheel

Div tooling

Main spindle:

Turning speed range: 20-6.300 min/-1

Power capacity: 6,3/10 kw

Maximum torque: 55/80 nm

Tool taper: SK40 (DIN 69871)

Rotary table:

Table surface area: 400 x 290 mm

T-Slots: 5 x 12H7 x 50

Center bore: 30H6

Rotation range: C 360°

Swivel range: B +105 / -15°

Feeds:

Feed speeds: 5000 mm/min

Rapid traverse ( X / Y / Z ): 5 m/min

Input unit: 0.01 mm

Power: 15 kVA, 400 V

2000 vintage.

DeckleDECKEL / MAHO DMU-35M is a five-axis simultaneous CNC machining center manufactured by DMG MORI for highly efficient modern machining. MAHO DMU-35M has a travel range of 500 x 330 x 350 mm, a working area of 1,000 x 600 mm and a fully enclosed working area for improved work safety. The motor spindles are driven by power transmission via belt drives with a maximum speed of 15,000 rpm and a maximum torque of 50 Nm. The machine is controlled by the Heidenhain Siemens Sinumerik 840D CNC with an MP2200 keyboard and a 19" tiltable Weisung display for easy accessibility. The machine has a double swivel rotary table with a locking range of ±135º and a ground slide saddle with a locking range of ±115º which allows for precise multitasking operations. The spindle is equipped with a direct drive spindle equipment featuring the latest air-cooled motor spindle for stable and precise machining. Equipped with a 8-tool disc-type tool changer with a capacity of 8 tools, the machine has an automatic tool measurement system to ensure accuracy of tool diameters and lengths. The tool changer automatically adapts to changes in tool dimensions. DECKEL DMU-35M has an integrated probe unit that can detect the location of each tool and workpiece in order to implement measurements and highly accurate machine settings. DMU-35M has an integrated laser technology that scans and detects the surface shape of a workpiece in order to generate smooth machine movements, ensuring consistently precise machine operation. The laser-assisted rapid traverse machine results in minimal production time. The integrated dry machining function reduces the residual moisture content of the workpiece, resulting in improved surface quality and longer life of the cutting tools. The chip conveyor helps in safe handling of chips with a central chip conveyor disposal tool. DECKEL / MAHO DMU-35M includes a modular safety asset designed to protect the operator and the machine at all times. The machine is also equipped with the latest environmental protection technology such as cooling power regulators. Overall, MAHO DMU-35M is an efficient and highly precise five-axis simultaneous CNC machining center designed with a variety of features to ensure accurate and precise machining with high speed and productivity. It is an ideal machine for producing small, precision parts with complex geometries.

There are no reviews yet