Used DECKEL / MAHO DMU-35M #9221571 for sale

URL successfully copied!

Tap to zoom

ID: 9221571

CNC Machining center

5-Axis (3 + 2)

X-Travel: 350 mm

Y-Travel: 240 mm

Z-Travel: 340 mm

Control: SIEMENS / SHOPMILL 810D

Spindle hours: 18,000

Chip tray

Elektr hand wheel

Div tooling

Main spindle:

Turning speed range: 20-6.300 min/-1

Power capacity: 6,3/10 kw

Maximum torque: 55/80 nm

Tool taper: ISO 40 (DIN 69871)

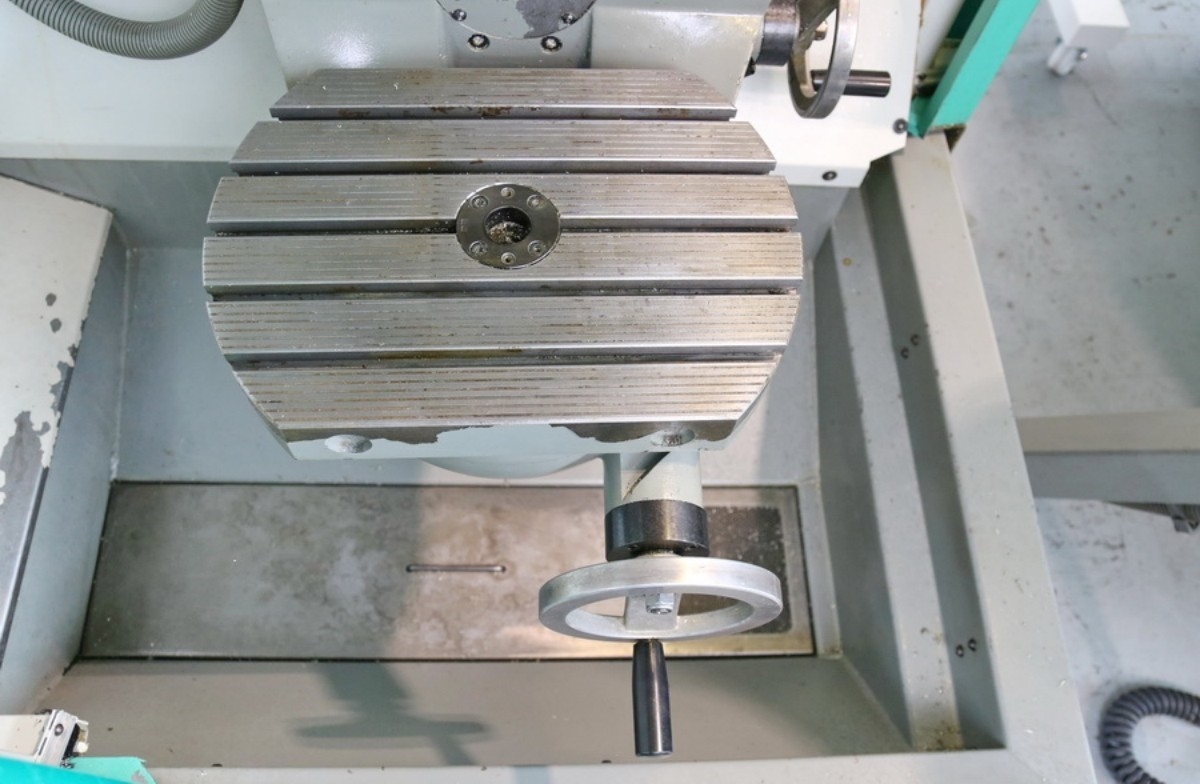

Rotary table:

Table surface area: 400 x 290 mm

T-Slots: 5 x 12H7 x 50

Center bore: 30H6

Rotation range: C 360°

Swivel range: B +105 / -15°

Feeds:

Feed speeds: 5000 mm/min

Rapid traverse ( X / Y / Z ): 5 m/min

Input unit: 0.01 mm

Power: 15 kVA, 400 V

2000 vintage.

DECKEL / MAHO DMU-35M is a universal machine tool for milling, drilling and grinding operations. It is a 5-axis multi-functional machine designed for applications in the automotive industry, aerospace engineering and tool making fields. MAHO DMU-35M is equipped with engineered components of superior quality, ensuring reliable and consistent performance even under high load conditions. This makes it an ideal machine for heavy-duty applications. The 5-axis configuration of DECKEL DMU-35M enables two full rotations around the x-axis and the b-axis, as well as a full 360 degrees rotation around the x-axis. This gives the machinist an extensive range of versatility and freedom when carrying out milling operations in 3D space. DMU-35M also features an ergonomic design with adjustable operator controls. This is coupled with a modern user interface, allowing for improved accuracy and repeatability of machining operations, as well as improved operator safety. DECKEL / MAHO DMU-35M is powered by a Siemens Sinumerik 840D CNC system, which is highly accurate and reliable, while responsive and simple to operate. The machine also features a spindle drive system with high torque, which allows for optimum performance under heavy loads. MAHO DMU-35M also includes a range of innovation systems, such as friction-reduced linear guides, a wear-resistant and durable table surface, and an optimal stiffness and rigidity design. This enables the machine to sustain loads up to 15,000 N, while dynamic processing at fast feed rates is also available. Finally, DECKEL DMU-35M also features robust and reliable tool management and spindle cooling systems, which help to maximize the profitability and longevity of the machine. The integrated chip and coolant management system ensures that chips are caught and coolant is managed during machining operations. Furthermore, the automatic tool changer has a rotating pallet-type storage, which holds up to 40 tools, speeding up production times and increasing productivity. Overall, DMU-35M is an advanced and highly versatile machine tool that is suitable for a range of industrial applications. Its innovative design, superior components and sophisticated software make it an ideal choice for those looking for reliable performance in a multi-functional machine.

There are no reviews yet