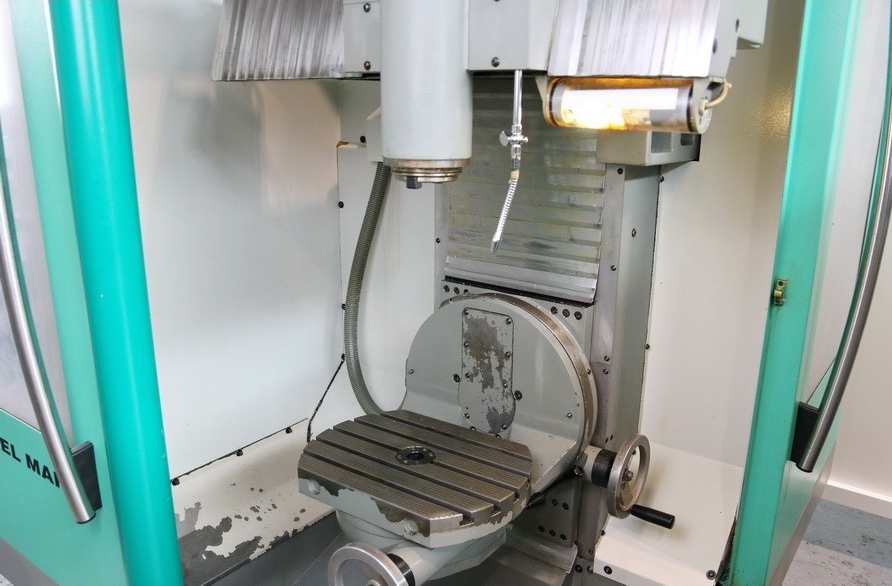

Used DECKEL / MAHO DMU-35M #9221576 for sale

URL successfully copied!

Tap to zoom

ID: 9221576

CNC Machining center

5-Axis (3 + 2)

X-Travel: 350 mm

Y-Travel: 240 mm

Z-Travel: 340 mm

Control: SIEMENS / SHOPMILL 810D

Spindle hours: 18,000

Chip tray

Elektr hand wheel

Div tooling

Main spindle:

Turning speed range: 20-6.300 min/-1

Power capacity: 6,3/10 kw

Maximum torque: 55/80 nm

Tool taper: ISO 40 (DIN 69871)

Rotary table:

Table surface area: 400 x 290 mm

T-Slots: 5 x 12H7 x 50

Center bore: 30H6

Rotation range: C 360°

Swivel range: B +105 / -15°

Feeds:

Feed speeds: 5000 mm/min

Rapid traverse ( X / Y / Z ): 5 m/min

Input unit: 0.01 mm

Power: 15 kVA, 400 V

2000 vintage.

DECKEL / MAHO DMU-35M is a five-axis CNC machine tool with a rigid cast iron frame construction, making it suitable for machining complex parts from a wide range of materials. The versatile MAHO DMU-35M has a maximum X-axis travel of 800 mm (31.5 inches), Y-axis travel of 500 mm (19.7 inches), Z-axis travel of 550 mm (21.7 inches) and an integrated swivel indexing table with a C-axis range of 200 degrees. DECKEL DMU-35M can accommodate workpieces weighing up to 1,000 kg (2,200 lbs) and features a 16,000 RPM motor spindle with a maximum torque of 70 Nm (511 inch-lbs) at 440 VAC. DMU-35M is equipped with the Heidenhain TNC 530 CNC control equipment, which has a 1.5 GB system memory, Ethernet connection, and a 10.4" color display that offers a wide range of programs and functions for efficient operations. The control unit also features four-axis simultaneous interpolation and digitizing of points, with asynchronous programming with G codes. DECKEL / MAHO DMU-35M features a number of technologies and components for improved accuracy and precision, including 24-position tool changer, linear roller bearings on all linear axes, a high performance, heavy-duty direct-drive motor spindle, a high-precision gear box, and a 30 kW high-power fan. MAHO DMU-35M has a servo-controlled B-axis for linear (or pin) interpolation, which can achieve an interpolation speed of up to 8 m/ min, and a C-axis table that can turn continuously in both directions for superior accuracy. DECKEL DMU-35M comes equipped with a range of features to ensure user safety, including a safety monitoring machine, guarding, emergency stop, and power sourcing failure protection. The machine is also capable of being manually operated directly from the frontpanel, giving added flexibility in terms of producing different part sizes without losing any accuracy due to manual operator errors. Overall, DMU-35M is a five-axis, 1,000 kg CNC machine tool that delivers productive, highly accurate machining of complex parts from a wide range of materials using high-precision gear boxes and motor spindles. With a range of safety features, high-performance direct-drive motor spindle, and an intuitive Heidenhain TNC 530 CNC control tool, DECKEL / MAHO DMU-35M is a great choice for machining operations that require superior accuracy and performance.

There are no reviews yet