Used DMG DMU-80 monoBLOCK #9216914 for sale

URL successfully copied!

Tap to zoom

ID: 9216914

Vintage: 2013

5-Axes machine center

X-Axis travel: 38.6"

Y-Axis travel: 24.8"

Z-Axis travel: 24.8"

A-Axis travel: 150°

B-Axis travel: 360°

Rapid rate (X/Y/Z): 1181 IPM

Rapid rate (A/B): 35/30 IPM

Table size: 49.2" L

Table size: 27.6" W

Main spindle

Spindle speed: 12000 RPM

Spindle motor: 20.10 HP

Spindle taper: CAT 40

Tool changer type: 32 ATC

Articulated axis: A1 Option

Tool change time C-to-C: 10 Sec

Options / Equipped with:

NC Rotary table integrated into fixed table

NC Rotary table (C-Axis)

NC Controlled swivel milling head (B-Axis)

Production package with internal coolant supply 20/40 bar through spindle center

600-L Coolant tank

Paper band filter

Rotoclear

Chip flusher in work area door

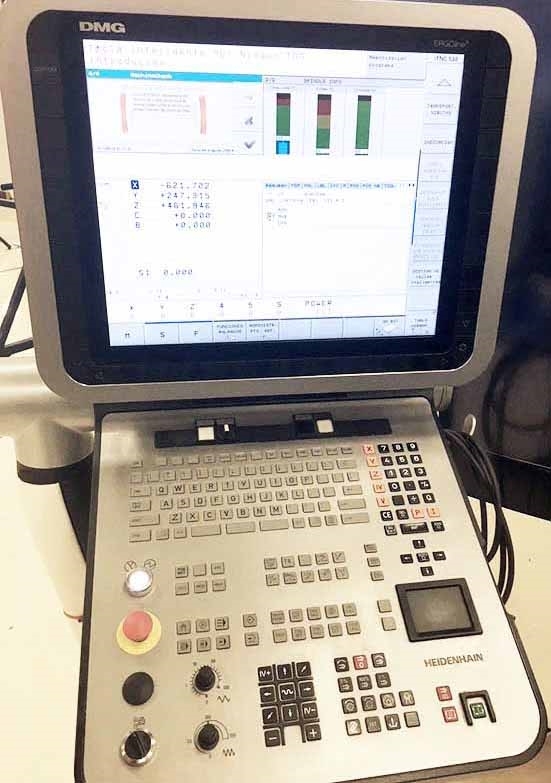

HEIDENHAIN TS 649

Tool measurement in work area through laser

Oil & emulsion mist separator

(4) Colors signal lamp

3D Quickset tool kit

3D CNC Control: ITNC 530

2013 vintage.

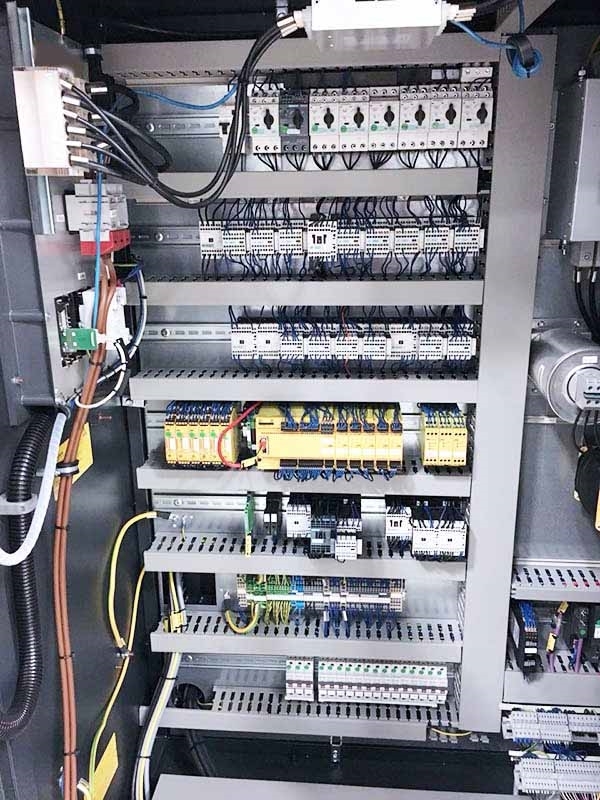

DMG DMU-80 monoBLOCK is a high-precision 5-axis machine tool designed for efficient and precise machining of complex parts. It features a powerful main drive spindle, rigid steel construction, and fully synchronized axis drives for smooth, accurate motion. The reinforced steel bed plate ensures maximum durability and minimal vibration during machining operations. This machine tool also has a large working area, enabling it to handle even large-sized parts. DMU-80 monoBLOCK is equipped with a Heawei 4 OS88M servo motor for the B-axis and a Siemens Sinamics S120 servo motor for the C-axis. This machine also features a backlash-free gear drive system with adjustable repeatability for precise control of the cutting force and motion. It further boasts of a high-performance CNC with the latest technologies, such as intelligent vertical programming and advanced look-ahead functions. This machine is also fitted with a variety of sensors, such as spindle speed sensor, workpiece speed sensors, and workpiece position sensors, to monitor the performance of the axis-drives during operation. This protects the machine against wear and overheating and keeps the machining process running smoothly. DMG DMU-80 monoBLOCK also has a programmable tool changer, which enables it to quickly and smoothly switch between different cutting tools without the need for manual intervention. DMU-80 monoBLOCK is also fitted with various safety features, such as the index safety stop, which discreetly stops the rotating parts for avoiding accidents. Additionally, it is equipped with a dust cover pick-up loop to detect operator presence and minimize dust particles. Overall, DMG DMU-80 monoBLOCK is designed to be a reliable and user-friendly machine with the latest technologies and safety features. This makes it ideal for machining small to large-sized parts from a variety of materials. Also, its flexible configuration makes it suitable for various applications, such as mould making, automotive, electronics, and aeronautics.

There are no reviews yet