Used DMG MORI HSC 75 Linear #9329367 for sale

URL successfully copied!

Tap to zoom

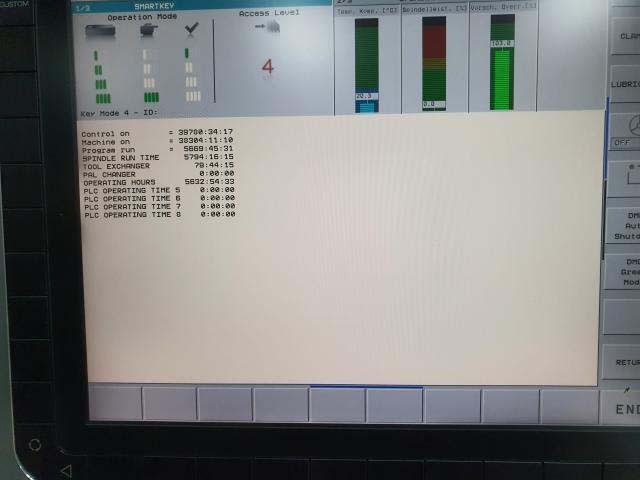

ID: 9329367

Vintage: 2012

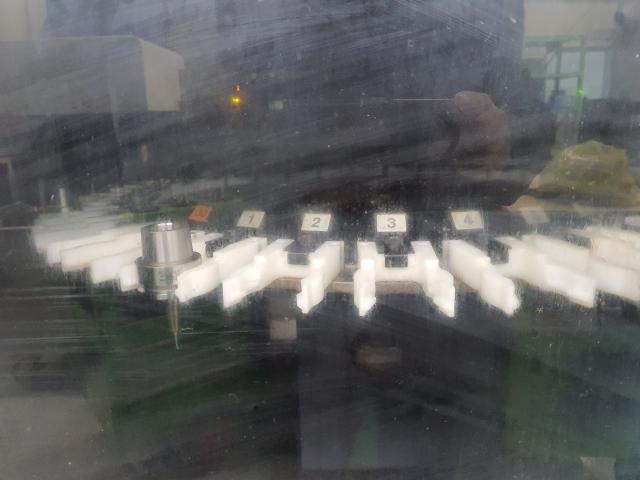

CNC Vertical machine center

5-Axis

HEIDENHAIN iTnc 530 CNC Controller

Table size: 37" x 25"

Maximum loading capacity: 1000 kg

Spindle speed: 28,000 RPM

HSK-A63

ATC: 30

Axis:

X-Axis: 750 mm

Y-Axis: 600 mm

Z-Axis: 560 mm

A-Axis: -10°

B-Axis: +110°

C-Axis: 360°

2012 vintage.

DMG MORI HSC 75 Linear is a high-speed machining center designed for producing precise, high quality parts in short production runs. The machine has a 75 mm spindle bore and a variable spindle speed up to 14,000 rpm. It is equipped with a precision linear guideway equipment for smooth rapid moves and improved positions. It is also equipped with a high-efficiency motor drive system that optimizes power and performance. With its high accuracy, high speed and efficiency, HSC 75 Linear is an ideal choice for a variety of manufacturing applications. DMG MORI HSC 75 Linear machine tool features an aluminum alloy bed and column for rigidity and vibration dampening. It is supported by four high precision linear guideways that offer a high degree of accuracy and dynamics. The design also incorporates roller bearing design to minimize artifacts from vibration and internal heat generated during operation. This all results in a longer tool life and improved productivity. Additionally, the work table is made of hardened steel and incorporated with a hydrostatic guideway unit. HSC 75 Linear machine tool is powered by a spindle motor with an output of 75 kW and a maximum torque of 55,000 Nm. This allows for fast, reliable machining processes with accurate control over the spindle speed, providing improved throughput and efficiency. The machine is further equipped with a high-energy, rapid traverse X/Y/Z axes to ensure smooth acceleration. In addition, DMG MORI HSC 75 Linear is fitted with a high precision measuring machine to enable precise dimensional measurements for a variety of materials and processes. The direct measuring tool measures distance to 0.0001mm and pitch to 0.0001mm accuracy. Together with the synchronized drive asset, this allows highly dynamic machining processes combined with optimum accuracy and surface finish. To ensure safety and quality assurance, HSC 75 Linear is equipped with a comprehensive array of pre-defined safety and monitoring systems that will detect any power off, spindle strain, or model failure. The machine also benefits from comprehensive dust and coolant management systems and an automatic chip-conveyor. All of this comes together to make DMG MORI HSC 75 Linear a high-performance machining center capable of producing precise, high-quality parts with minimal time and cost.

There are no reviews yet