Used DMG MORI NLX 2500/1250 #9375875 for sale

URL successfully copied!

Tap to zoom

ID: 9375875

Vintage: 2018

CNC Lathe

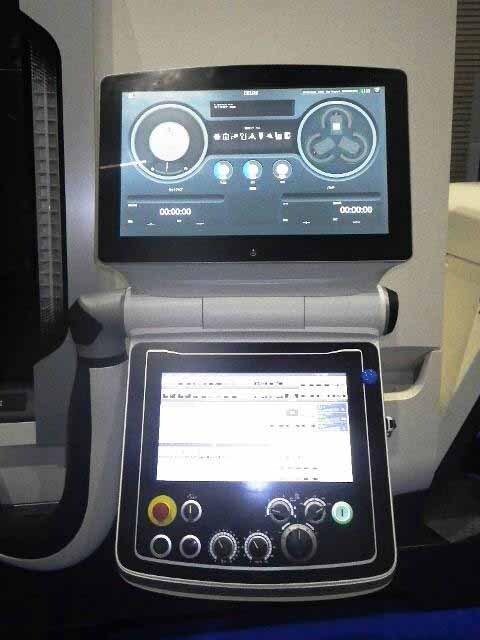

MITSUBISHI Meldas-730UM control

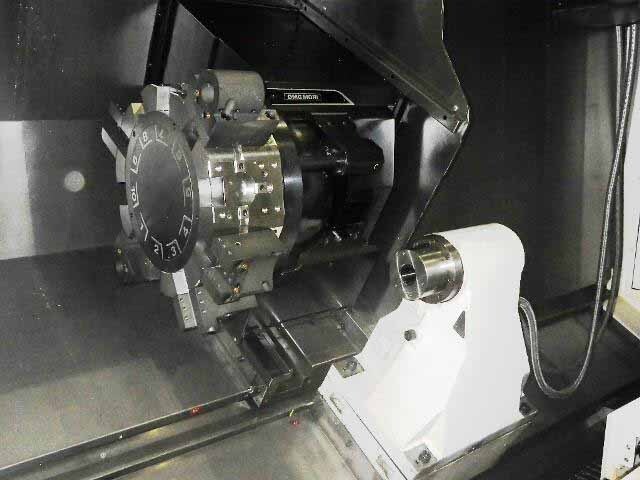

KITAGAWA Hollow, 10" Chuck

Maximum working diameter: 366 mm

Maximum working length: 1255 mm

Stroke (X,Z): 260 x 1345 mm

Spindle speed: 4,000 RPM

Spindle through hole: 91 mm

(10) Turret stations

Tailstock

Chip conveyor

2018 vintage.

DMG MORI NLX 2500/1250 is a next generation machine tool that is designed to provide flexible and efficient machining operations in all types of applications. This machine tool is constructed with high rigidity and low friction components to provide excellent accuracy, repeatability, and reliability while minimizing vibration and noise levels. In terms of its construction, the NLX 2500/1250 is designed with a box-type base and a column that has a ribbed structure for high rigidity. This design reduces thermal and mechanical deformation of the machine by evenly distributing forces and providing vibration dampening during processing. The spindle head is located on the top of the column and is designed to provide smooth, harmonic oscillations while retaining high accuracy in operation. Furthermore, its spindle speed ranges from 45-12,000 RPM for optimal machining control. The NLX 2500/1250 is equipped with a manual control equipment and various contour cutting functions. The manual control system provides operators with easy and intuitive operation while also providing a range of features such as automatic tool changing, spindle speed adjustment, coolant pressure adjustment, and more. Furthermore, the contour cutting functions enable the NLX 2500/1250 to perform efficient, precise machining operations such as contouring, drilling, and tapping without manual intervention. The NLX 2500/1250 is further equipped with advanced cutting technologies including high-speed milling, high-feed milling, and electro-discharge machining. The machine is capable of producing very high quality parts with a minimum of effort from the machine operator. Moreover, the machine has a high-accuracy measuring unit for quality control and inspections and features automatic tool monitoring and wear detection for maintenance and safety. The NLX 2500/1250 has numerous user-friendly features as well, such as an air separator chips collector and a coolant filter moisture separator to help reduce noise and vibration, an eco-friendly oil mist nozzles to reduce coolant misting and improve working conditions, and a soft jog mode that allows for easy and comfortable machine set up. Finally, its digital conversational programming enables easy program adjustments and editing. In summary, DMG MORI NLX 2500/1250 is an advanced, next-generation machine tool that has been designed with efficient and reliable components and systems that provide minimal vibration and noise during operation. Its manual control machine, cutting functions, and cutting technologies enable efficient, precise machining operations for a range of applications. The machine also has user-friendly features and digital conversational programming for easy program adjustment and editing.

There are no reviews yet