Used DOOSAN MECATECH PUMA MX 2000 ST #9153781 for sale

URL successfully copied!

Tap to zoom

ID: 9153781

Vintage: 2007

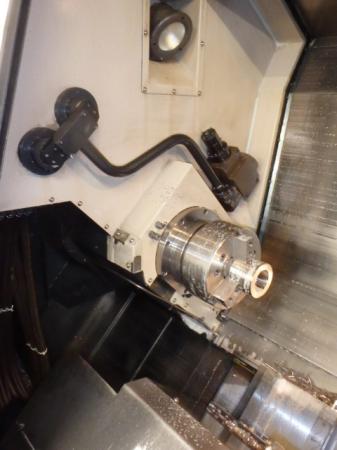

CNC Turning / milling center

Control: Fanuc 18 iTB

Input power: [kW] 22

Subspindle

Input power: [kW] 22

CNC-Spindle tilting for cutting and turning opertations

B-Axes

Equipment:

Bar loader magazine IEMCA Kurzstangenlader / IEMCA short mag feed

Collets: Kitagawa B 210 & B 206

Collet chuck system: Crawford

(1) Amount of turrets

C-Axis

Turning diameter: [mm] 550

Bar capacity: [mm] 65

Working hours: [h] 6.431

Spindle running time: [h] 4.684

2007 vintage.

DOOSAN MECATECH PUMA MX 2000 ST is a highly advanced machine tool for turning, drilling, and grinding complex parts and materials. It is an economically priced turning center designed for small and medium-sized parts production. It is capable of precise turning with high level of accuracy. The MX 2000 ST is equipped with a powerful direct drive spindle, the most reliable direct drive motor technology in the market. It runs at a maximum speed of 10,000 rpm with a maximum torque of 270 Nm. The spindle speed is electronically variable from 50 to 10,000 rpm. The feed rate for the C-axis is 0.001˚ per step, with a maximum indexing time of 0.03s for one full revolution. The large and rigid X-axis bed provides a wide variety of applications and maximum machining speed for the component. It has an extended Y-axis that allows for the machining of long parts and a 12-station turret for simultaneous machining of two sides of the workpiece. The turret holds up to 12 tools at once, allowing for consecutive operations such as face/groove/pocket milling, drilling, and tapping. The MX 2000 ST is equipped with a Fanuc-3i Series-C control unit, which can store up to 50 programs in its memory. The robust and reliable construction of the CNC unit provides both accuracy and productivity. The table surface is coated with a hard-wearing material, which helps reduce vibration and provide improved accuracy and smooth motion. The MX 2000 ST is designed with a wide range of accessories including a chuck, live tooling, and an on-board coolant system. It is easy to operate and maintain with user-friendly controls and a self-diagnosis system that encourages efficient production. PUMA MX 2000 ST is ideal for high-precision parts with small turning diameters and complex geometry. It is an efficient and versatile machine for drilling, threading, and milling, as well as complex finishing operations.

There are no reviews yet