Used DOOSAN MECATECH V850M #9213033 for sale

URL successfully copied!

Tap to zoom

ID: 9213033

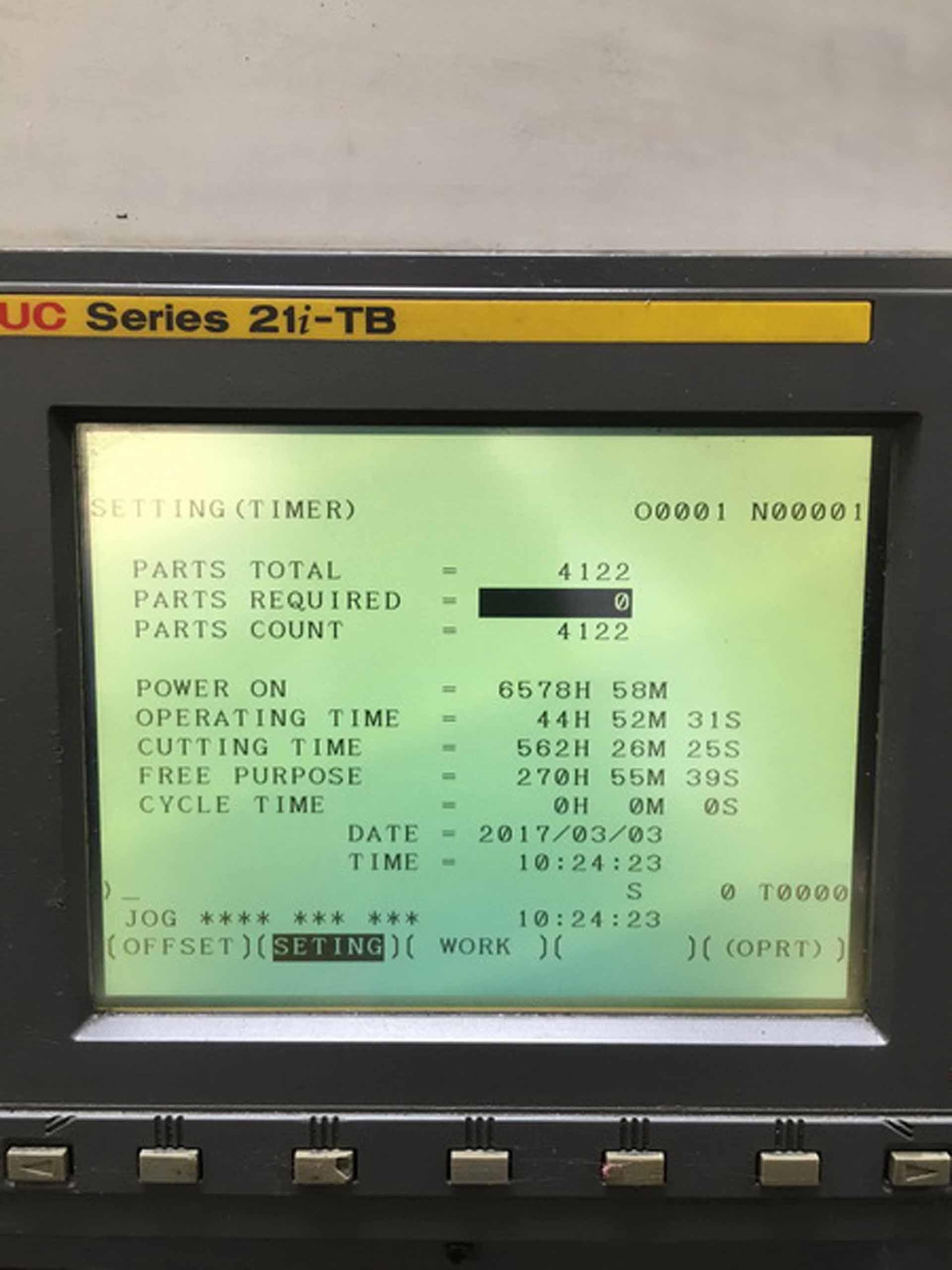

Vintage: 2005

CNC Vertical boring / Milling center

X - Axis travel: 18.50"

Z - Axis travel: 33.46"

Chuck size: 31.5"

Maximum swing: 39.46"

Spindle speed: 1800 RPM

Maximum cutting diameter: 33.46"

Maximum cutting height: 33.3"

(2) Gear ranges

Maximum table capacity: 1475 lbs.

Maximum torque: 1,796 ft/lbs.

Spindle nose: A2-11

Spindle bearing diameter: 7.87"

Table horse power: 50/40 HP AC

Spindle indexing: .001 N/C Contouring

Rotary tool: 4000 RPM

Rotary tool: 10 HP

Rapid traverse rate: 630/630 IPM

Turret configuration: (12) Stations

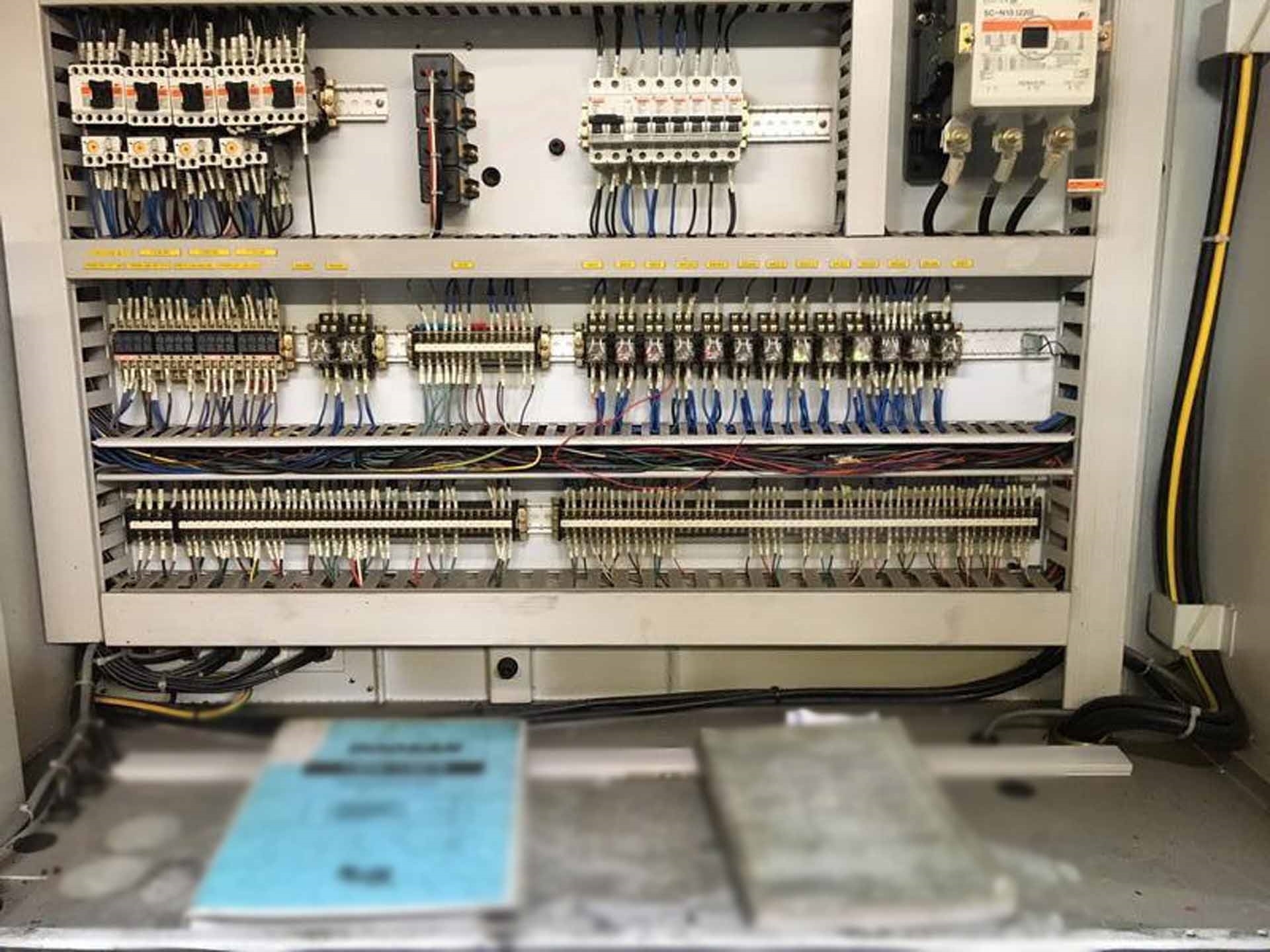

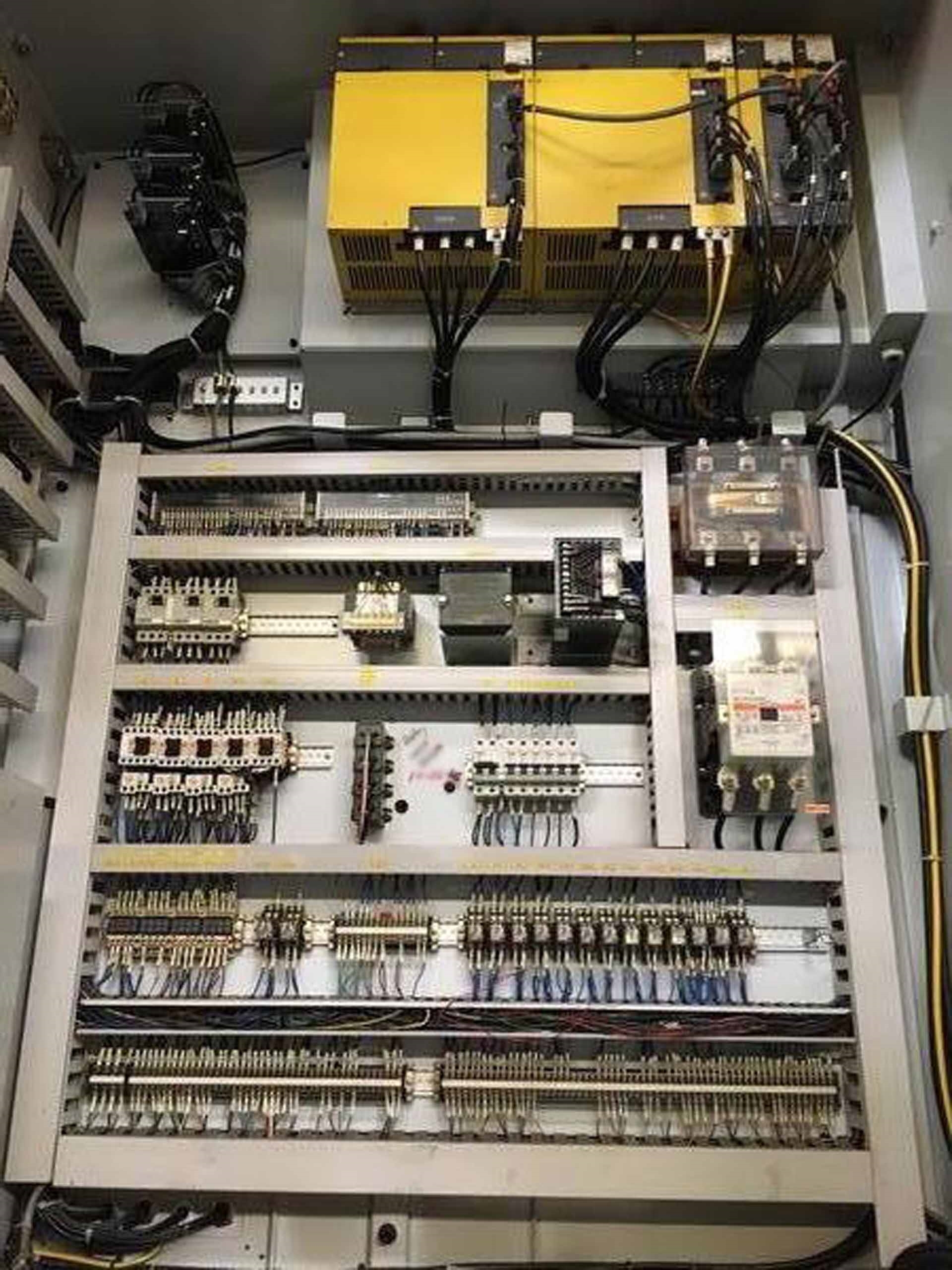

Options / Equipped with:

FANUC 21ITB CNC Control

Rigid tapping

Tool life management

Thread cutting

31.5" 3-JAW Chuck / Jaws included

X-Axis spindle Indexing

C-axis spindle indexing

(12) Station turret VDI tool holders

(2) Speed high-low direct drive spindles

(2) Axial live holder rotary heads

(2) Radial live tool holders

(3) Turning tool holders

(2) Boring bar holders

(4) Turning tool holders

Telecopic guards / coolant shields

Coolant system

Side discharge chip conveyor

Tool holders

Manuals

2005 vintage.

DOOSAN MECATECH V850M is a versatile machine tool for machining, drilling, and cutting that can be used in a variety of applications. V850M is a vertical machining center that is equipped with a built-in Fanuc Control equipment. This machine tool provides impressive machining speed, accuracy, and reliability with its sophisticated, advanced technology. DOOSAN MECATECH V850M is equipped with a large working volume allowing for larger components to be used. Its 30 horsepower (hp) high torque spindle with 51 foot-pounds of torque and a maximum spindle speed of 7500 revolutions per minute (rpm) provides the ability to quickly and accurately complete tasks. The machine has a maximum table load of 1,700 kilograms (kgs) and a maximum X, Y, and Z-axis travel of 800 millimeters (mm), 500 mm, and 500 mm, respectively. An advanced Fanuc Control system is incorporated into this machine tool for improved automation and control. The Fanuc Control unit is capable of running automated processes, as well as manual processes that can be controlled using its intuitive touch-screen interface. The Fanuc Control machine also provides complete monitoring and control over the machine's cutting performance as well as an efficient off-line programming capability for setting up complex machining tasks. V850M also utilizes advanced components such as its rigidly designed frame structure and efficient linear guide slides that provide impressive speed and accuracy while machining. Its high-precision spindle provides excellent cutting quality and accuracy. Together with the machine's high torque spindle, it gives a smooth finish on a large variety of components. The tooling and fixturing on DOOSAN MECATECH V850M are designed to provide optimal accuracy and positioning for machining different materials. The tooling options available include automatic tool changers, live tooling, etc. The built-in tool capability enables the machine to be set up and operated quickly and reliably. This powerful and versatile machine is designed with safety in mind and has features to protect the user. V850M also includes several integrated features to reduce machine downtime, such as its "auto-detect" tool which detects any potential problems and alerts the user accordingly. DOOSAN MECATECH V850M is the perfect machine for machining, drilling, and cutting operations in a variety of applications. With its advanced technology and reliable components, this machine tool can be relied on to provide high-quality, accurate and fast machining operations, saving time and money.

There are no reviews yet