Used EDEX ATOZ700-IS170 #9311422 for sale

URL successfully copied!

Tap to zoom

ID: 9311422

Vintage: 2014

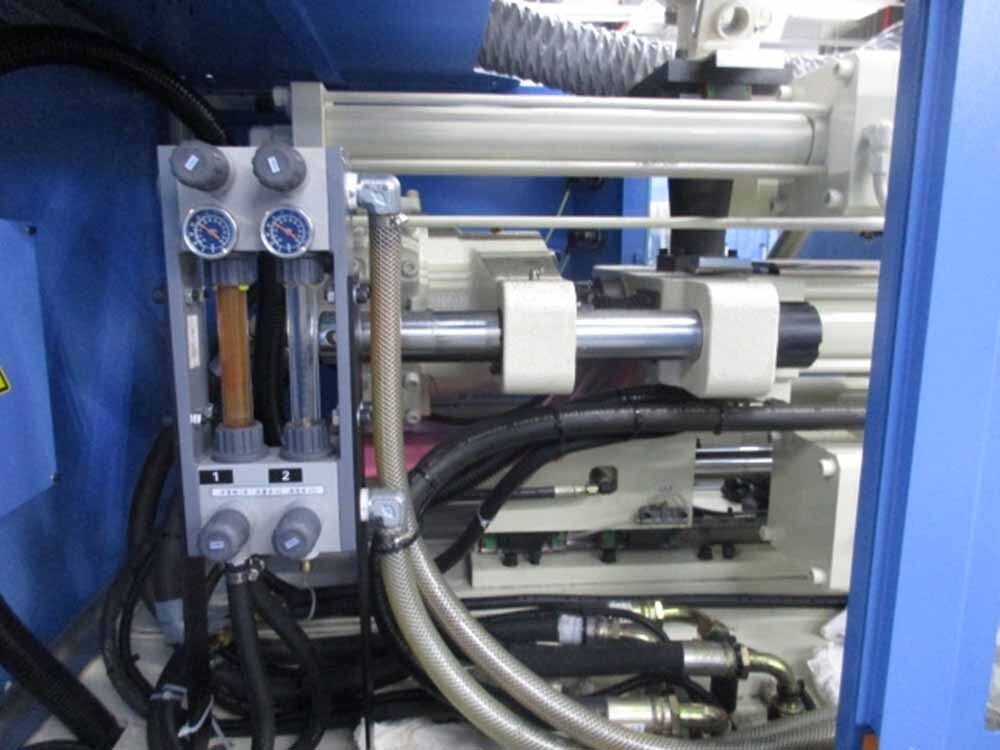

Injection molding machine

Clamping force: 71

(4) Cylinders

Direct pressure locking mode

Linear slide pillar movement

Mold clamping system: Potentiometer

Template movement distance: 0.5 mm

Die-closing low-pressure

Precision measurement method: Detective

Corinth column interval: 360 x 360 mm

Template size: 580 x 580 mm

Maximum template distance: 600 mm

Mold opening stroke: 100 mm

Finished product thickness: 2.5 times

Minimum mold thickness: 150 mm

Nozzle head: ϕ3 mm, R10

Maximum injection pressure: 2125 kgf/cm

Maximum holding pressure: 2125 kgf/cm

Maximum injection speed: 151 mm/s

Targeting locating ring

Electric heating sections: N2+H3

Maximum heating temperature: 310°C

Heating temperature control accuracy: ±1°C

Heating time: 20 to 30 minutes

Thimble drive mode: Oil pressure

Thimble stroke: 100 mm

Thimble speed: 697 mm/s

Position accuracy of thimble: 0.05 mm

Ejection method:

Repeated demolding

Vibration demolding

Screw speed: 320 rpm

Screw diameter: 30 mm

Screw stroke: 150 mm

Theoretical injection capacity: 106 cm³

Injection quality: 111.3 g

Injection quality accuracy: 0.2 mm

Plasticizing capacity: 106 cc

Screw area: 7.07 cm²

Plasticizing capacity: 0.6 kg/min

Energy consumption: 2.9

Electric heating capacity: 5.3 kW

Motor power: 10 kW

Noise level: < 80 dB

Upper edge: 1.6

Standard equipment:

LCD Screen

Potentiometer

Water collectors

(4) In

(4) Out

Oil temperature control

Feed temperature control

Male and female mold temperature control

Wind support switch

Power plug set: 220 V, 30 A x2

Room temperature water: 6-Points

Energy saving system:

TOSHIBA Servo motor

German internal gear pump

Less oil leakage concerns

Dry cycle time: 2.5 ~ 3.5sec

No welded tubing

Power supply: 220/380 V, 3-Phase

2014 vintage.

EDEX ATOZ700-IS170 is a precision machine tool specifically designed for the machining of complex parts and components. It is a highly reliable and versatile machine featuring a distinctive spindle construction that is designed for optimal rigidity. This allows for accuracy and outstanding performance when facing, cutting and drilling operations. The machine is equipped with an INTEGREX control, which allows for sophisticated and easy programmability as well as a wide range of control parameters that can be modified to suit a range of machining needs. EDEX ATOZ700-IS170is constructed with a highly rigid 70 mm spindle head that is capable of spinning up to 6000 RPM, and up to a maximum cutting speed of 10,000 metres per minute without losing torque or vibration. It also features an Automatic Tool Changer (ATC) that can handle up to 30 tools, minimising downtime associated with tool changing. Access to the high precision spindle is provided by a generously sized door that helps reduce noise levels while enabling the efficient entry of tools and allowing easy and fast measurements. Other essential features of ATOZ700-IS170 include thermal displacement detectors for measuring spindle temperature; thermal displacement sensors on the rotating and non-rotating components; excellent feed-rate control; and a powerful and efficient lubrication system. This reliable machine also comes equipped with an automatic magazine complete with special components for milling, drilling, and cutting operations; automatic axis positioning systems and a cutting-pressure monitoring system to ensure smooth, uniform cutting. EDEX ATOZ700-IS170 is designed for maximum flexibility due to its range of main and sub-port machine tools such as turret attachments, burrs, drills, and other special tools. It is also an energy-efficient machine featuring an AC servo spindle drive system for maximum torque control and energy savings while rotating. This versatile and efficient machine is well-suited for various applications in the aerospace, automotive, general machining, die and mould, and medical industries, and is sure to meet the needs of any operation. With its focus on reliability, efficiency, and cost-effectiveness, ATOZ700-IS170 promises an outstanding performance no matter the task at hand.

There are no reviews yet