Used EDEX ATOZ700-IS170 #9311636 for sale

URL successfully copied!

Tap to zoom

ID: 9311636

Vintage: 2014

Injection molding machine

Clamping force: 71

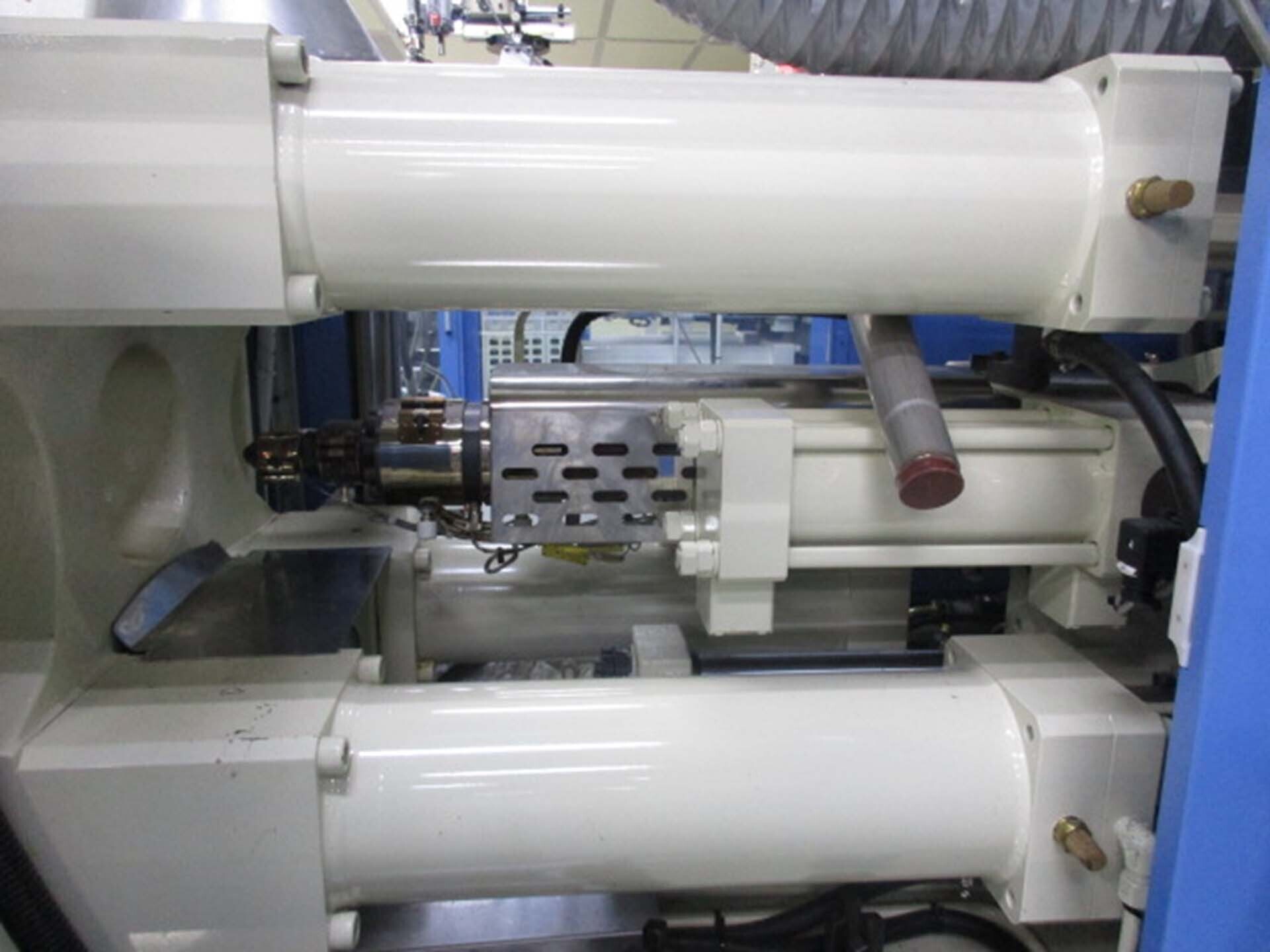

(4) Cylinders

Direct pressure locking mode

Linear slide pillar movement

Mold clamping system: Potentiometer

Template movement distance: 0.5 mm

Die-closing low-pressure

Precision measurement method: Detective

Corinth column interval: 360 x 360 mm

Template size: 580 x 580 mm

Maximum template distance: 600 mm

Mold opening stroke: 100 mm

Finished product thickness: 2.5 times

Minimum mold thickness: 150 mm

Nozzle head: ϕ3 mm, R10

Maximum injection pressure: 2125 kgf/cm

Maximum holding pressure: 2125 kgf/cm

Maximum injection speed: 151 mm/s

Targeting locating ring

Electric heating sections: N2+H3

Maximum heating temperature: 310°C

Heating temperature control accuracy: ±1°C

Heating time: 20 to 30 minutes

Thimble drive mode: Oil pressure

Thimble stroke: 100 mm

Thimble speed: 697 mm/s

Position accuracy of thimble: 0.05 mm

Ejection method:

Repeated demolding

Vibration demolding

Screw speed: 320 rpm

Screw diameter: 30 mm

Screw stroke: 150 mm

Theoretical injection capacity: 106 cm³

Injection quality: 111.3 g

Injection quality accuracy: 0.2 mm

Plasticizing capacity: 106 cc

Screw area: 7.07 cm²

Plasticizing capacity: 0.6 kg/min

Energy consumption: 2.9

Electric heating capacity: 5.3 kW

Motor power: 10 kW

Noise level: < 80 dB

Upper edge: 1.6

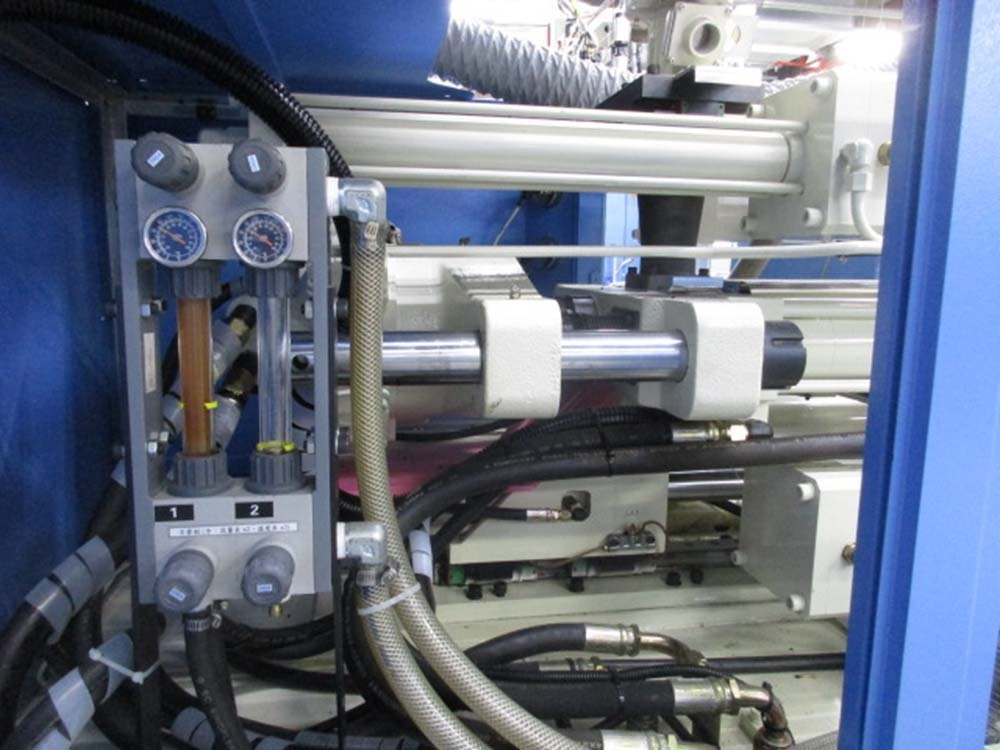

Standard equipment:

LCD Screen

Potentiometer

Water collectors

(4) In

(4) Out

Oil temperature control

Feed temperature control

Male and female mold temperature control

Wind support switch

Power plug set: 220 V, 30 A x2

Room temperature water: 6-Points

Energy saving system:

TOSHIBA Servo motor

German internal gear pump

Less oil leakage concerns

Dry cycle time: 2.5 ~ 3.5sec

No welded tubing

Power supply: 220/380 V, 3-Phase

2014 vintage.

EDEX ATOZ700-IS170 machine tool is an advanced CNC machining center designed specifically for the high-precision metalworking industry. The machine is equipped with a 170-degree built-in rotary indexing table, ideal for producing high-tolerance parts with high accuracy, precision, and repeatability. It is capable of complex 3-axis, 4-axis, 5-axis indexing, swivel, taper milling, drill/tap machining, and many other sophisticated machining operations. ATOZ700-IS170 CNC machining center is constructed of heavy-duty cast iron, measuring 6,000mm from side to side and 4,000mm in depth. Its spindle is powered by a 16.0 kW (25 HP) Makino PDS-176M motor spindle that operates from 6,000 to 24,000 RPM, allowing for speeds up to 400 IPM (inches per minute). The machine is also equipped with two independent spindle drives and interchangeable spindles to accommodate different types of tooling. For even greater accuracy, EDEX ATOZ700-IS170 is fitted with a Thermacon high-pressure and high-speed coolant system and a rigid Tapping System. For efficient operation, ATOZ700-IS170 is equipped with a Fanuc Oi-MD CNC Control with Manual Guide-i advanced intuitive programming software. This software has several features, such as Smart Functions, Multi-Skill Level, 3D Simulation, and Remote Monitoring. The Fanuc Oi-MD CNC Control can receive G-code data, use macros for complex machining operations, and is capable of advanced editing and CNC programming. Additionally, EDEX ATOZ700-IS170 is equipped with linear scales on the X, Y, and Z axes to ensure rapid, precision positioning accuracy and repeatability. ATOZ700-IS170 CNC machining center provides superior performance in a variety of manufacturing operations. Its robust construction and advanced technological features ensure precision and accuracy, making it an excellent choice for high-quality machining applications. With its wide array of features, EDEX ATOZ700-IS170 provides outstanding repeatability and unsurpassed speed and performance.

There are no reviews yet