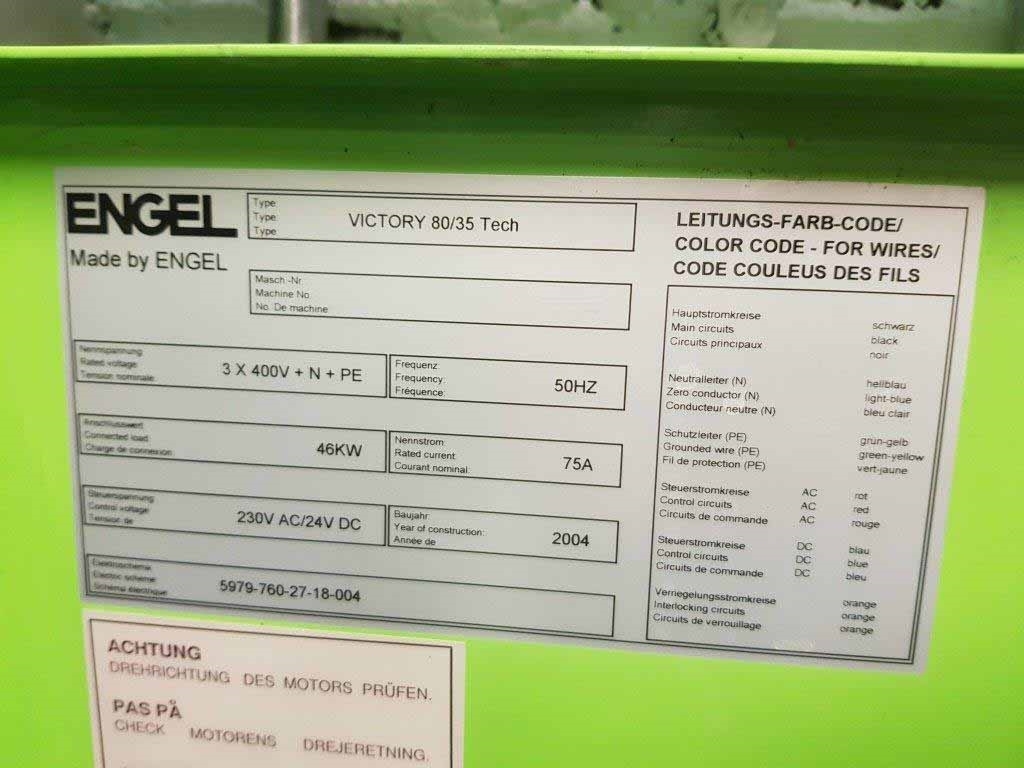

Used ENGEL Victory 80 / 35 #9210618 for sale

URL successfully copied!

Tap to zoom

ID: 9210618

Vintage: 2004

Injection molding machine

Hydraulic core pilling: Hydraulic gate valve

Screw diameter: 18

2004 vintage.

ENGEL Victory 80 / 35 is a state of the art CNC machine tool designed for high speed machining and production. Its impressive features include a powerful spindle, an advanced CNC control, a highly engineered linear guide equipment, and a host of other features designed to maximize machine performance and productivity. Victory 80 / 35 comes equipped with a 18.5KW spindle with optional power ranging up to 40kW. The spindle is capable of operating at both high speeds (up to 5,000 rpm) and low speeds (down to 400 rpm) and is suitable for a wide range of machining applications. The control system includes a FANUC 0-MD CNC with a Windows-based graphical user interface. The control offers a wide range of features and machining options including programming in G and M Codes, and CAD-CAM interfacing. ENGEL Victory 80 / 35 has an impressive linear guide unit. The guide ways are made of cast iron and are designed for smooth and precise traveling. This ensures consistent accuracy and excellent surface quality in your part. The guide ways are complemented by the machine's advanced spindle drive machine which provides improved positioning accuracy, extending tool life and machining speed. Victory 80 / 35 has a wide range of accessories designed to increase its versatility and productivity. The tool magazine can hold up to 60 tools and has a double arm to optimise chip flow. An integrated washing cabinet is also available to keep your cutting tools clean and operating at peak performance. In addition, a revolving brush cleaning device is installed to ensure smooth chip removal. ENGEL Victory 80 / 35 is a rugged and reliable machine tool, designed to stand up to the rigors of continuous production. Its mechanical components are built for long-term use and its control tool is state-of-the-art, allowing users to quickly and easily program, monitor and troubleshoot their machining operations. The components and systems are all designed to increase productivity and performance, allowing users to maximize output with minimal downtime.

There are no reviews yet