Used EUROTECH 420SLL #9200701 for sale

URL successfully copied!

Tap to zoom

ID: 9200701

Vintage: 1999

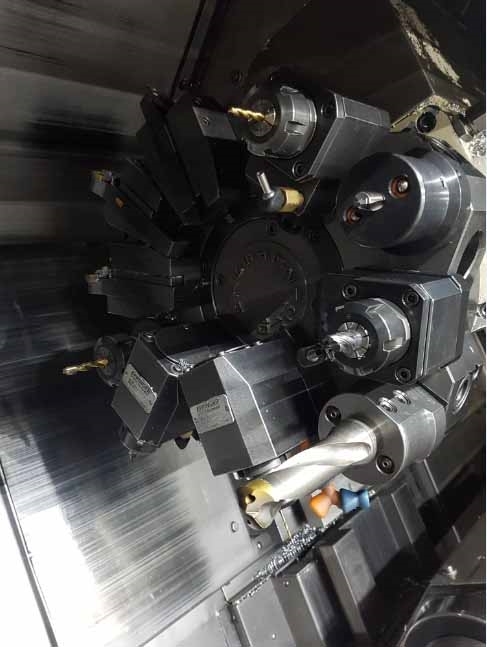

CNC Turning / Milling center

Control: FANUC 18iT

Main spindle bar capacity: Ø 1" 5/8

Maximum cut diameter spindle 1: Ø 7.87"

Maximum cut diameter spindle 2: Ø 6.3"

Maximum turn length main: 11.81"

Maximum turn length sub-spindle: 7.87"

Spindle speeds main / Sub-spindle: 5000 RPM

Maximum live tool speed: 4,000 RPM

Spindle motor: 20 Hp

Sub-spindle: 10 Hp

Rotary: 5 Hp

Spindle indexing (main & sub): 0.001°

Number of tool positions upper / Lower: 6/12

Number of live positions upper / Lower: 6/12

Equipped with: Lemca boss-542, 12" magazine bar feeder

Parts ejector

Twin spindle

(3) X-axis live tool holders

(4) Z-axis live tool holders

B42 Collet system main and Sub-spindles

Sub-spindle air blast

1999 vintage.

EUROTECH 420SLL is a high-performance machine tool developed by EUROTECH for working with stainless and steel materials. It features a steel bed design that provides excellent rigidity and dampening throughout the design. It has a maximum spindle speed of 12000 rpm and delivers maximum torque of 120 Nm. It incorporates a high-speed linear servo motor for superior cutting performance. The spindle motor and the linear servo motor are controlled by advanced CNC controls, providing precise and repeatable machining conditions. 420SLL is designed for high-precision machining applications requiring the highest standards of accuracy and repeatability. It combines a solid cast iron structure, precision linear guides and high-grade bearings to provide a highly rigid machining platform. Its highly capable tool changer and automatic work area can be used to quickly process complex parts requiring fine surface and intervening machining. It is equipped with dual spindles and a multi-axis headstock and tailstock, allowing for complete 5-axis simultaneous operation. EUROTECH 420SLL features a range of automation and customization options to ensure it can meet the diverse needs of its users. Its intuitive CNC control systems provide high-level operator safety. In addition, its flexible ATC (Automated Tool Changer) enables the machine to quickly and efficiently change tools to help keep production costs down. It also features programs such as 3D machining, which allows for the most complex of geometries. It also benefits from a number of standard safety features, including improved guarding, an emergency stop button, and a fire suppression system. 420SLL is the ideal machine tool for operations that require precise and repeatable machining, high-level safety conditions, and extended cycle times. It is capable of working with a wide range of materials, including stainless and steel, while its heavy-duty construction ensures extreme metal removal rates. In addition, its advanced CNC control system and range of automation options make it perfect for working on complex parts involving multiple operations.

There are no reviews yet