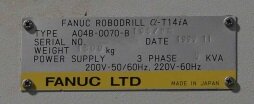

Used FANUC Robodrill α-T14iA #9201103 for sale

URL successfully copied!

Tap to zoom

ID: 9201103

Vintage: 1999

CNC Vertical machining center

Specifications:

Table size: 25.59" x 14.96"

Maximum table load: 440 Lbs

Spindle nose to table top: 5.9"-17.71"

Travel:

X-Axis: 19.6"

Y-Axis: 14.96"

Z-Axis: 11.81"

Rapid traverse rate X,Y & Z: 1889 Ipm

Cutting feed rate: 0.1 - 787 Ipm

Spindle speeds: 80 - 8000 Rpm

Spindle motor: 7.5 Hp

Spindle taper: BT 30

Tool changer capacity: 14 Station ATC

Equipped with:

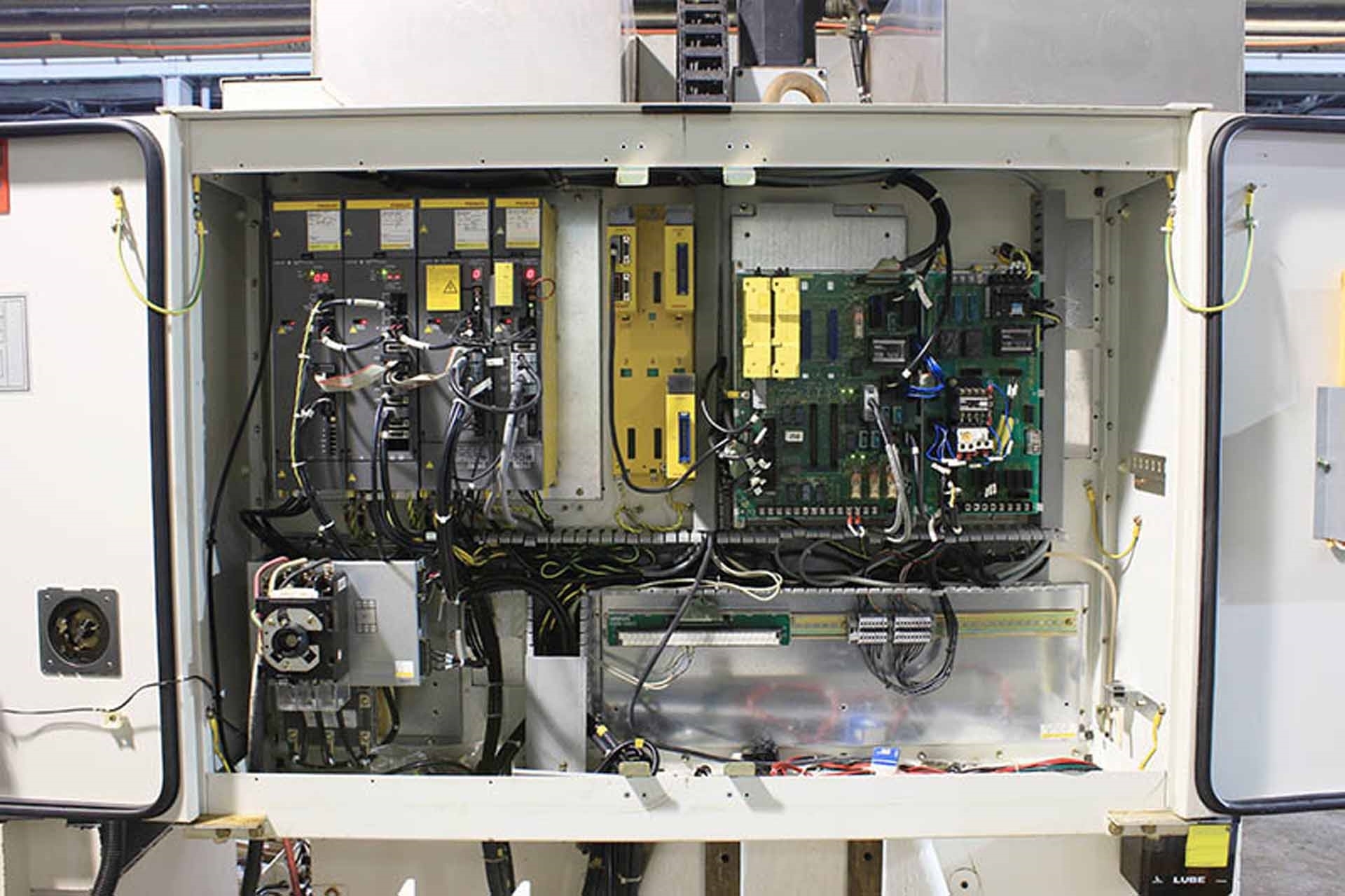

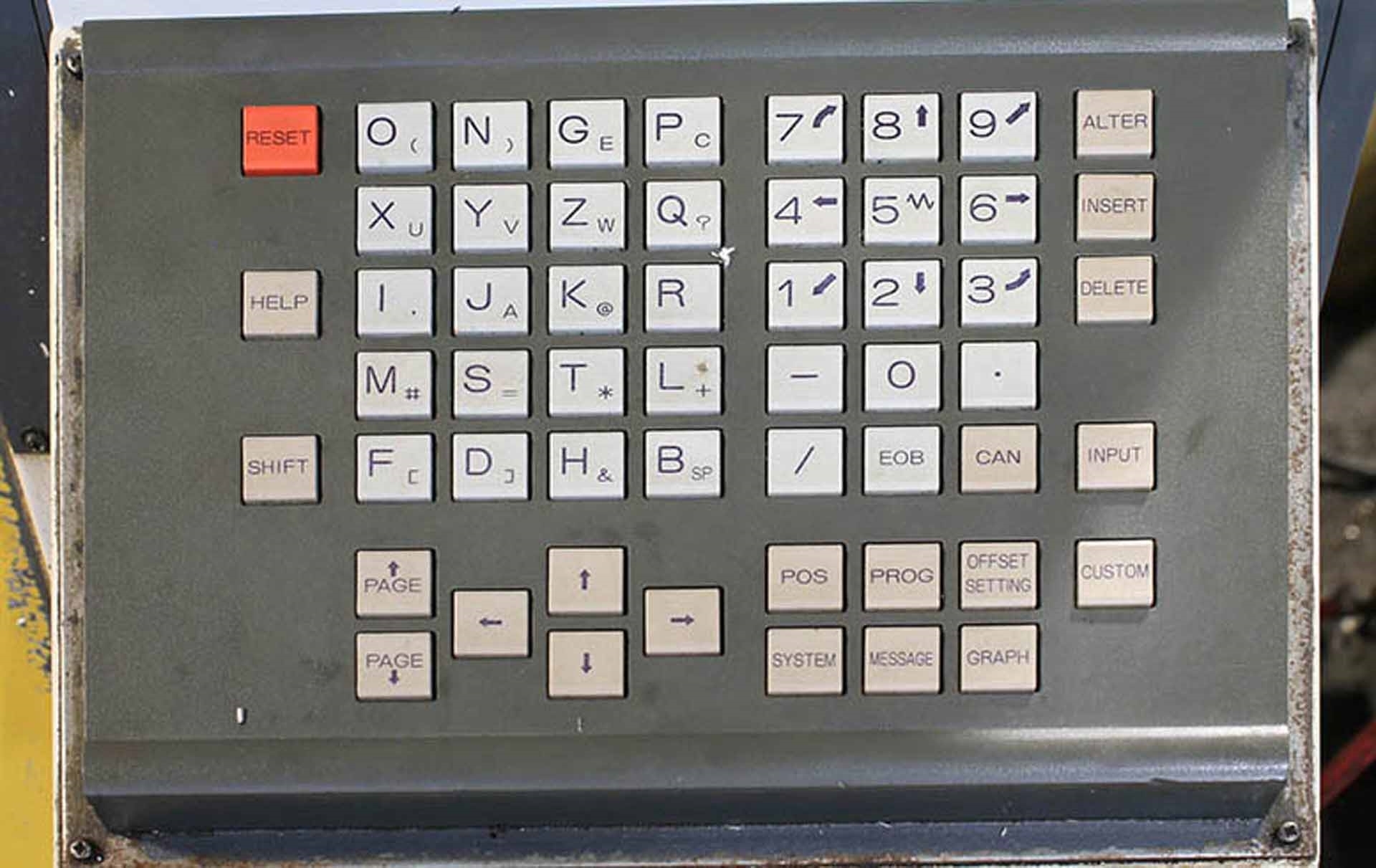

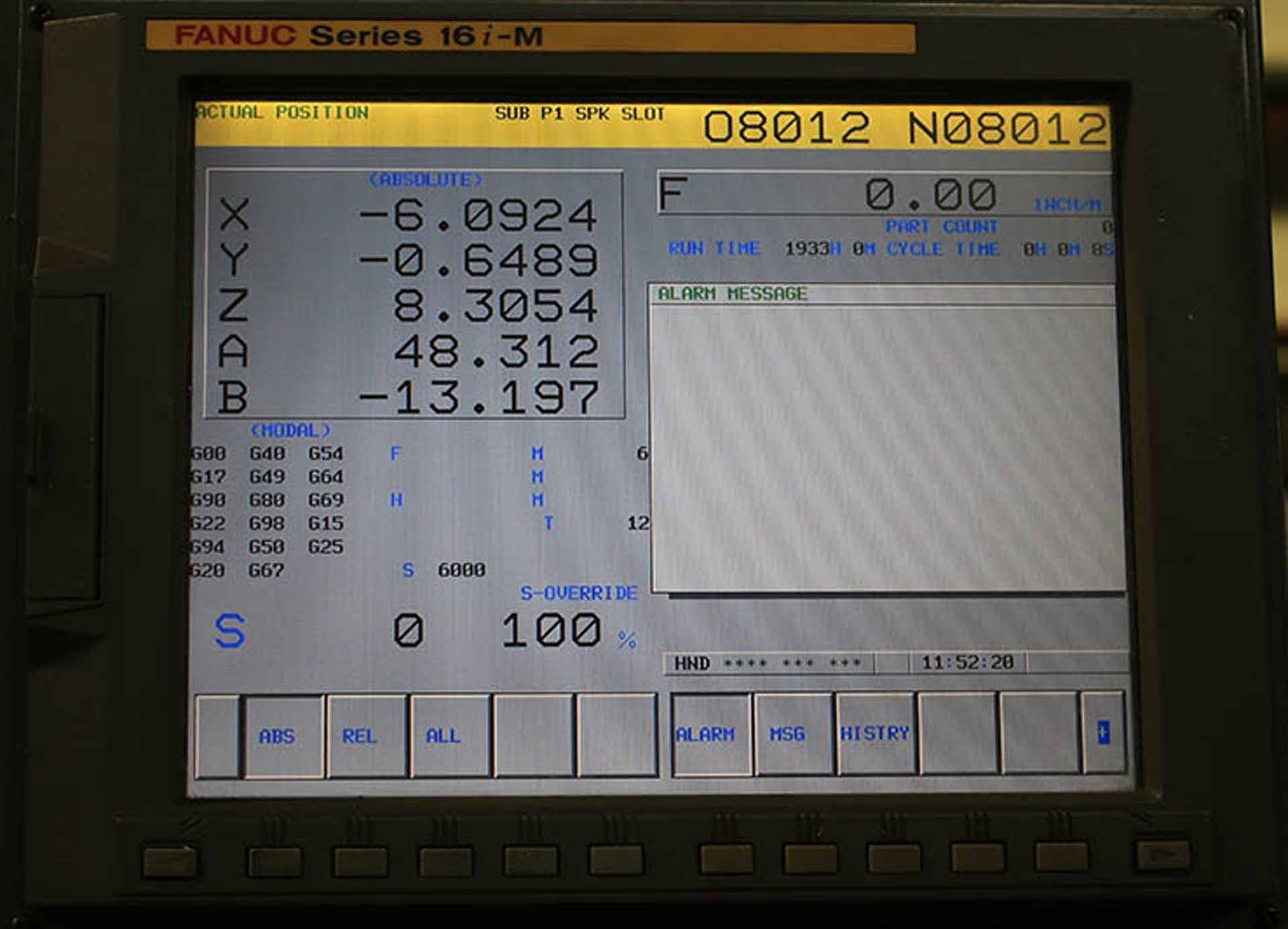

FANUC 16i-M CNC Control

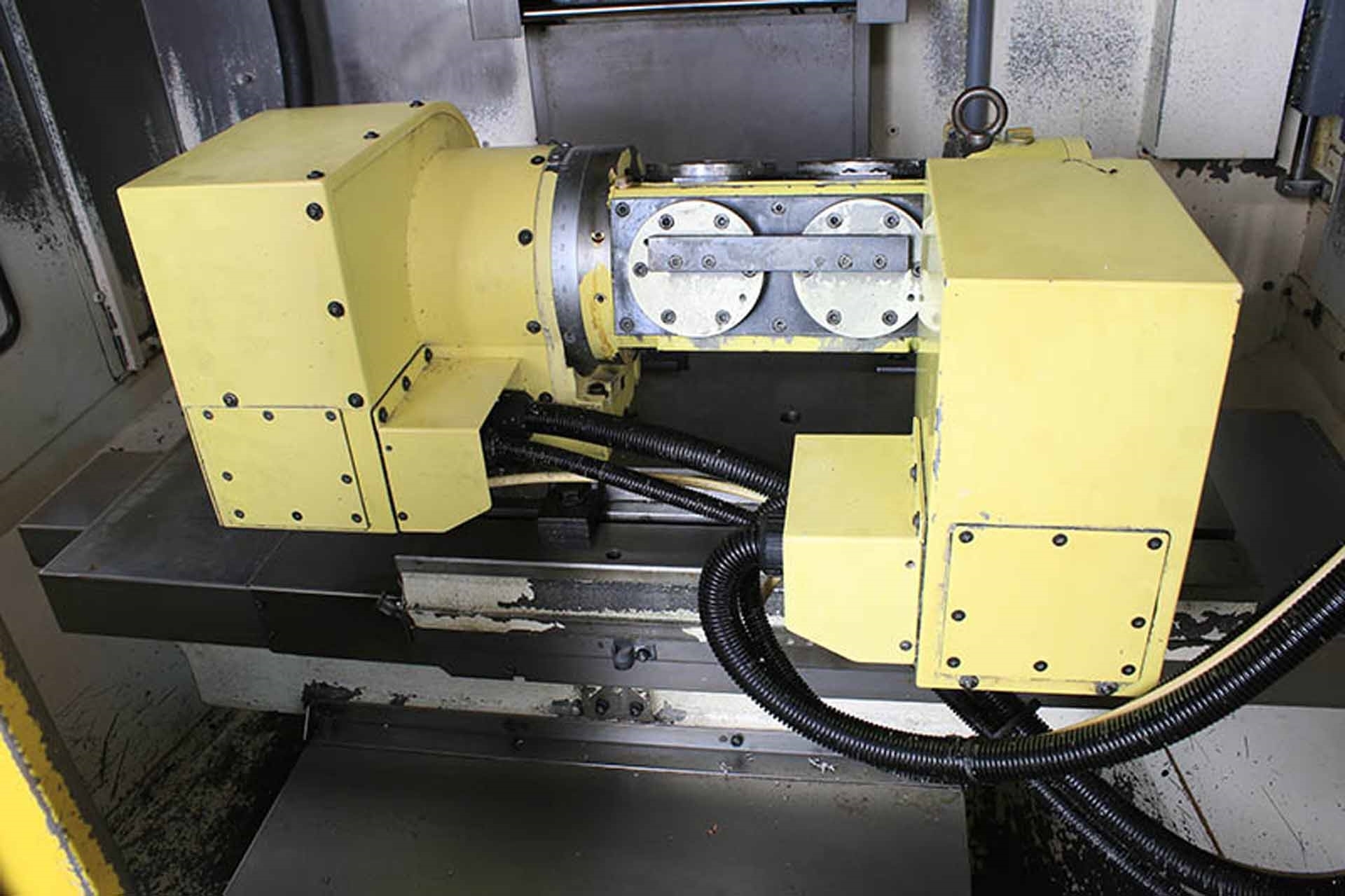

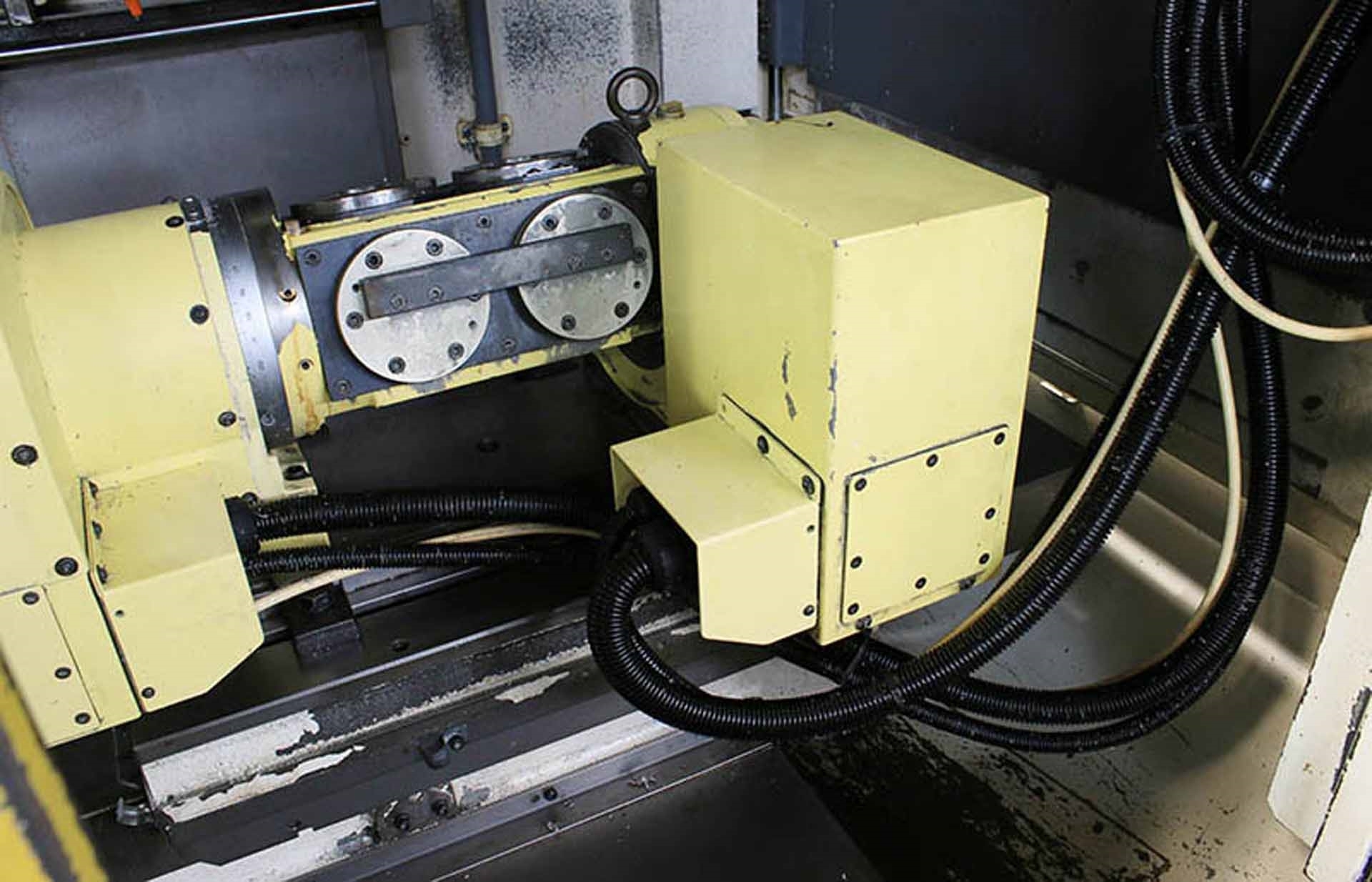

NIKKEN 5AX-2MT-105-120 Dual platten 5 axis trunnion

14-Position turret

Rigid tapping

BARNES Series 30 kleenall chip conveyor & filter

Currently warehoused

1999 vintage.

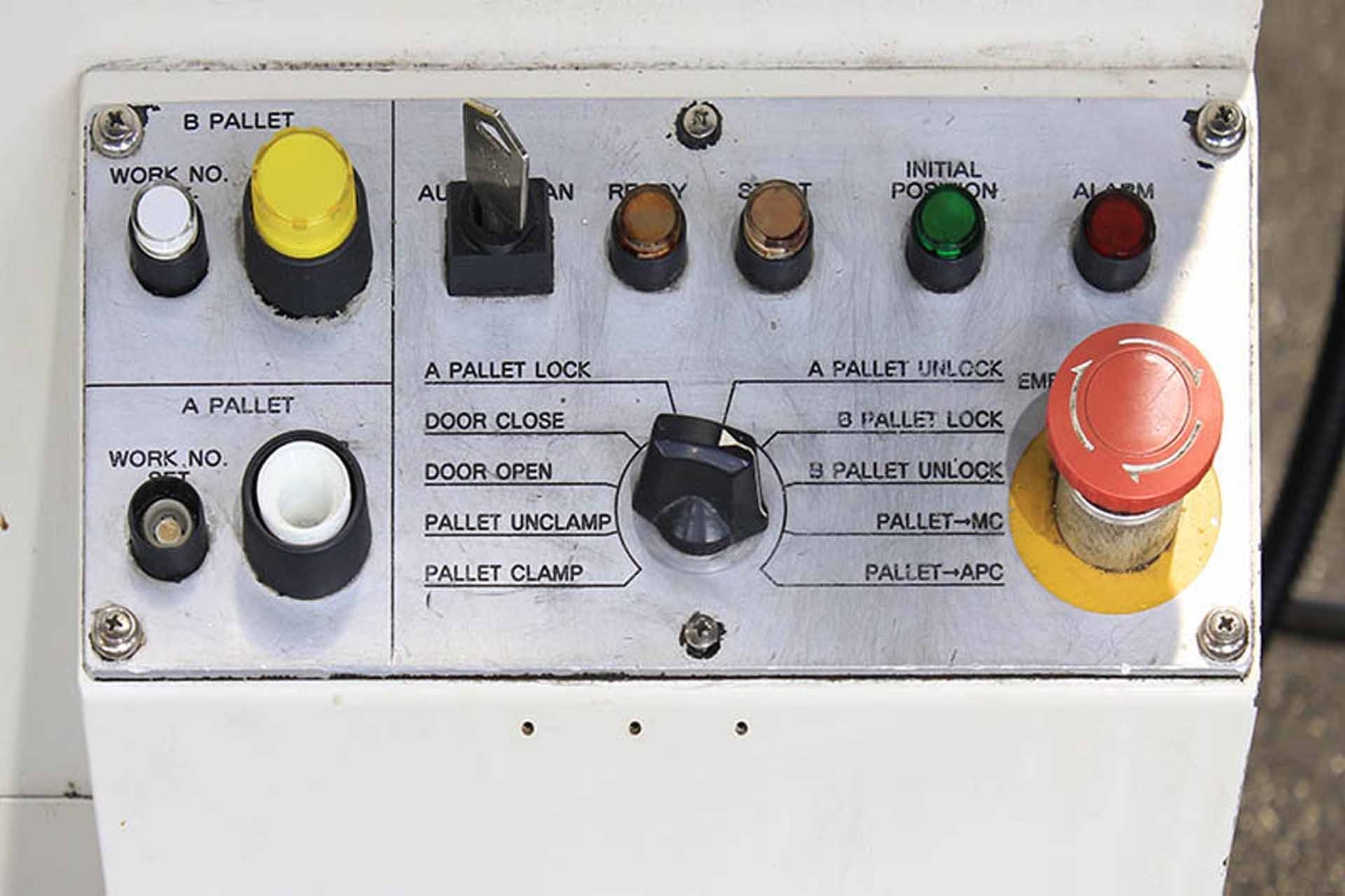

FANUC Robodrill α-T14iA machine tool is a versatile, high speed, computer-controlled drilling and machining center that combines simple setup and operation capabilities. It is equipped with a high-speed, three-axis CNC spindle that can move the tool up to seven times faster than traditional methods. Additionally, the Robodrill features a multi-axis through-spindle coolant, B-axis milling, and synchronized tapping capability to provide users with flexibility, precision, and speed. The α-T14iA has a 30 tool changer that can load tools up to 10 kilograms and a high speed spindle that can go up to 12,000 rpm. It has a 6,000-rpm spindle that can make contour or face cuts and can work with a variety of materials such as steel, aluminium, and composites. Its axis travel ranges are X320mm, Y300mm, Z410mm and it has a work area of 160 x 300mm for basic machining operations. The precision spindle bearings also ensure accurate positioning of the headstock. The machine has high accuracy, repeatability, and durability due to its precision ballscrews for each axis. It also has an integrated automatic pallet changer for high volume production. The cutting feeds can be programmed in a step-by-step manner and the feed rate can vary from 0.01 to 7,000rpm depending on the job. The Robodrill has an optional self-tuning in-process measuring system for automatic tool and workpiece inspection and a powerful control system that allows users to maintain precise settings and program complex, high-volume jobs. It also has a memory function to store workpiece parameters and programs so that users can run multiple jobs quickly and easily. Robodrill α-T14iA machine tool is designed to deliver high-precision results while eliminating costly errors. Its simple setup and operation capability, durability, and flexibility makes it a great choice for a variety of industrial applications. In short, the Robodrill is an accurate, reliable, and versatile machine tool well-suited for complex machining jobs.

There are no reviews yet