Used FEMCO HL-25 #9093128 for sale

URL successfully copied!

Tap to zoom

ID: 9093128

Vintage: 2000

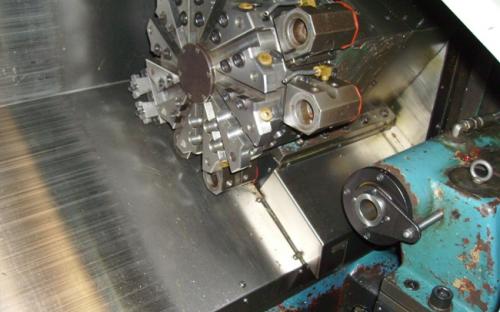

CNC Lathe

Chuck Size 8"

Max Diameter Bar Capacity 2.05"

Max Swing Over Bed 17.72"

Max Turning Diameter 11.81"

Distance Between Centers 25.59"

Max Machining Length 23.62"

Spindle Speed 48 - 4800 RPM

Spindle Bore 2.4"

Spindle Nose A2-6

Spindle Motor 20 / 15 HP AC

Tools 24 (12 OD + 12 ID)

Rapid Traverse Rates (X / Z) 1180 / 1417 IPM

X-Axis Travel 5"

Z-Axis Travel 24.8"

Tailstock Taper MT#4

CNC Control: FANUC 0i-TC

9" Monochrome CRT

8" Auto Strong N208 Hydraulic Chuck

Programmable Tailstock

Chip Conveyor (Side Exit)

Yellow Condition Light

2000 vintage.

FEMCO HL-25 is a top-of-the-line machine tool designed for precision machining. It is a horizontal CNC lathe, with a rigid, robust design and is available in two different bed lengths. Its high-accuracy finish is achieved through advanced design and engineering features such as the box-type bed structure and double-nut ball screw feed equipment. This allows for improved surface finish, part accuracy, and increased machine stability. The construction of HL-25 is composed of two main parts: a cast iron bed and a steel headstock. Its robust box-type bed design and long ridges create an extra-stable platform that lets users fine-tune cutting parameters and minimize vibration. This helps ensure a 10 micron accuracy when machining round or cylindrical surfaces. The machine also features a double-nut ball screw feed that gives a stronger and more accurate feeding. The headstock of FEMCO HL-25 is loaded with cutting-edge features. It features a high-torque spindle, which helps reduce cutting time by providing great power and torque. This spindle is also equipped with a servo-driven, 8-position turret with direct-drive tools for high-speed drilling and tapping. The spindle motor uses special drive belts that provide superior performance and increased life expectancy. The powerful and precise features of HL-25 are controlled by a Fanuc O-TD CNC system. This unit is easy to learn and provides a range of specialized machining functions for high-precision production. The user can also customize many of the settings, including spindle speeds, feed rate, and cutting parameters. Overall FEMCO HL-25 is an advanced machine tool for precision machining. Its combination of cutting-edge features and powerful control machine lets users produce high-precision components with maximum efficiency and accuracy. Its robust construction and advanced design also ensure long-term durability.

There are no reviews yet