Used FLOW I-4800 #9074378 for sale

URL successfully copied!

Tap to zoom

ID: 9074378

Vintage: 2007

Water jet cutting system

Design: Integrated Flying Bridge

Travels

X-Axis: 96"

Y-Axis: 48"

Z-Axis: 8"

Contouring Feed Rate: 300" / Min.

Rapid Traverse Rate: 500" / Min.

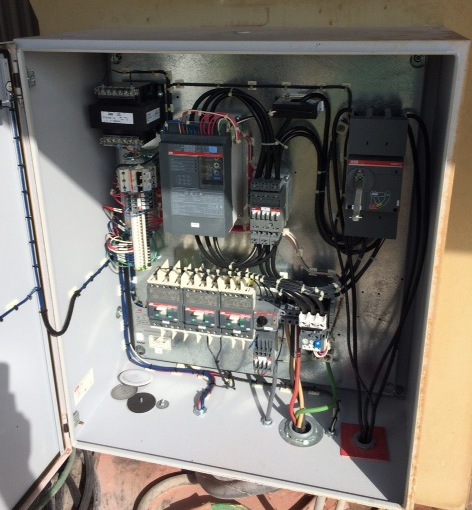

Motor: 50 HP 3/60

50i-S II ESL Intensifier Pump:

ESL Intensifier Pump Documentation Package

60,000 PSI Intensifier Pump Tool Kit

Consumable Parts Kit

Inlet Water Test Kit

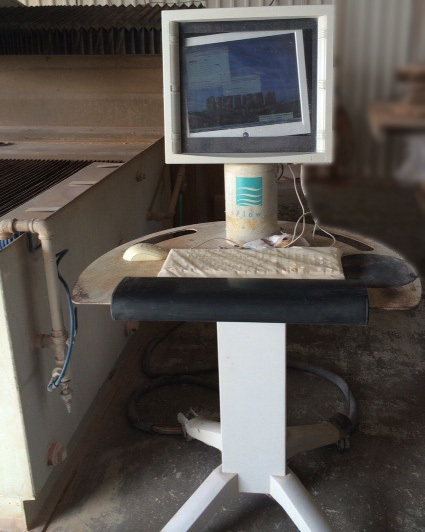

FlowMaster PC-Based Controller:

FlowPATH Software

FlowCUT Software

Raster-to-Vector Software

FlowMaster Professional CAM-Connect Package w/ FlowCode Software

FlowLINK Software

CleanCut Material Support System

High-Pressure Whip Plumbing Package

PASER ECL Plus Abrasive Jet Cutting System:

Single Mounting Bracket

Abrasive Bulk Transfer System; 500 Lb. Capacity

PASER ECL Start-Up Kit

DuraFlow Orifice Mount Assembly

2007 vintage.

FLOW I-4800 waterjet cutting machine is capable of producing intricate shapes and tight radius curves in almost any material, from the most delicate materials to super alloys and composites.I-4800 is the pinnacle of FLOW innovative intra-day productivity programming software, which enables the equipment to exponentially increase production rate and output with fewer operators.FLOW I-4800 utilizes a 50 hp intensifier pump that generates pressures up to 87,000 psi and allows for multiple cutting heads and lower jet consumables usage, consequently making the machine one of the most efficient and accurate waterjet cutting machines available. I-4800 also has superior motion control systems, such as Servo-Drive controls and Linear Actuator System technology, which are vital for a variety of unique features and increased productivity. The robust DC servo drives are capable of reaching up to 1G of acceleration and speeds up to 1800 inches per minute, while the Linear Actuator Unit technology uses high precision ball sliding and recirculating bearing mechanisms for smooth, precise, and reliable motion control. What sets FLOW I-4800 apart from other waterjet cutting machines is its unique abrasivejet cutting capabilities, which allows for high precision cutting of hard materials. I-4800 uses a single cutting head that can be switched between waterjet and abrasivejet functions with minimal downtime. In addition, FLOW I-4800 uses G-Force™ technology to improve cutting accuracy and reduce blade stop time. This revolutionary software features an in-depth motion planning machine that enables I-4800 to reach cutting speeds of up to 60,000 inches per minute, while maintaining very tight tolerances and an unsurpassed machine life. FLOW I-4800 is also equipped with a variety of advanced safety features such as auto-shutdown and safety switches for maximum operator safety. The machine also uses a rigid, all-weld fabricator steel frame, an enclosed blast shield and oil containment design, and an easy to use operator interface for maximum keep and intuitive use. Overall, I-4800 waterjet cutting machine is the ideal machine tool for high-precision and production-level applications. It is ideal for cutting a wide variety of applications, from the most delicate to the most difficult materials. With its unique waterjet and abrasivejet capabilities, state of the art motion controls, and advanced safety features, FLOW I-4800 is the perfect solution for any cutting company that is seeking maximum efficiency and quality.

There are no reviews yet