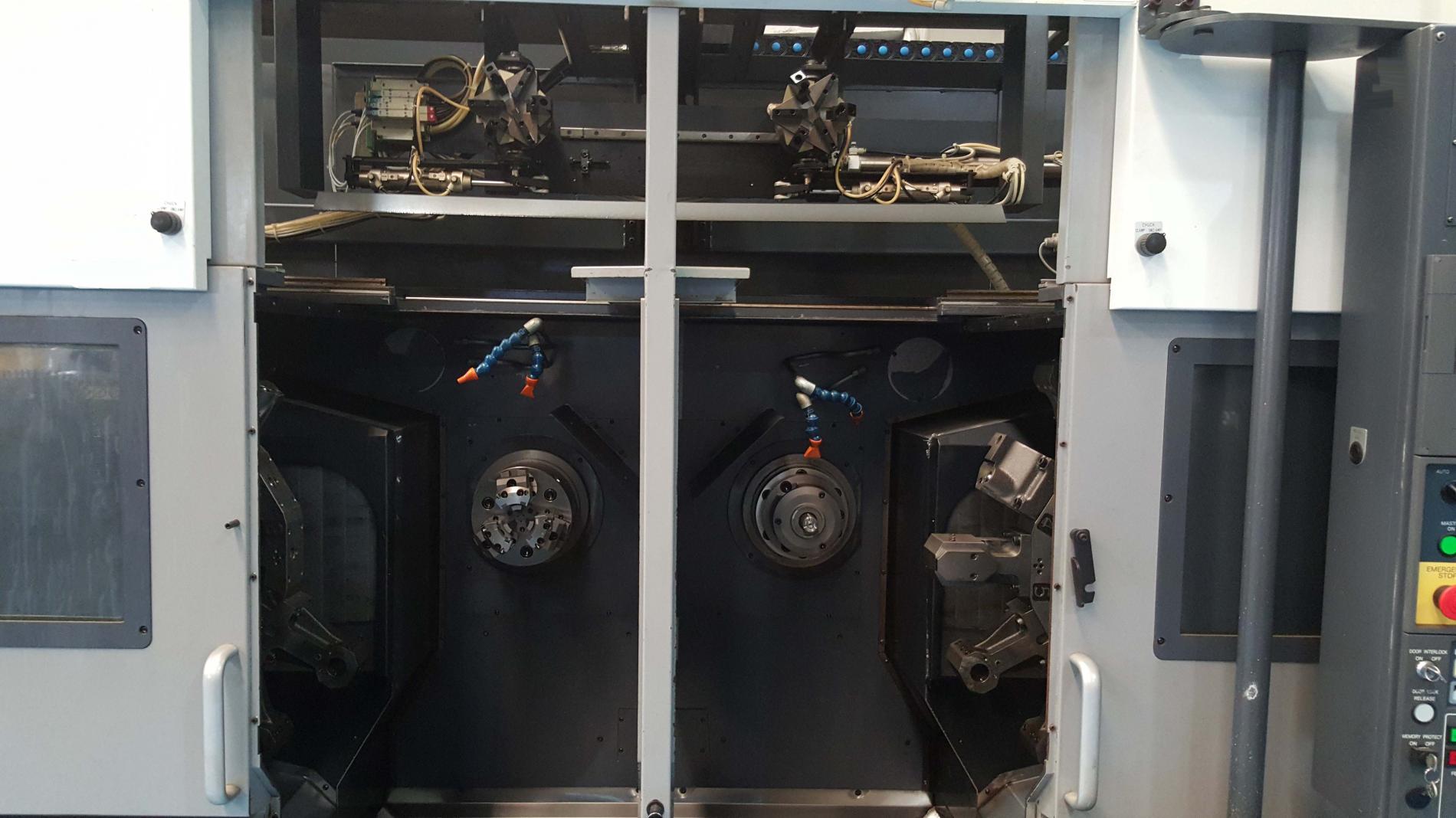

Used FUJI CSD-400 #9145070 for sale

URL successfully copied!

Tap to zoom

ID: 9145070

Vintage: 2013

Parallel twin spindle CNC lathes

With built in gantry loader LX-30B

Standard automatic cell

Material used: Aluminum

Z-Axis travel: 12.4"

X-Axis travel: 7.68"

Spindle diameter: 4.72"

Spindle nose: A2-8

Spindle bore: 2.64"

Maximum spindle speed: 2200 RPM

FANUC Oi-TD CNC Control

Spindle motors: 25 HP

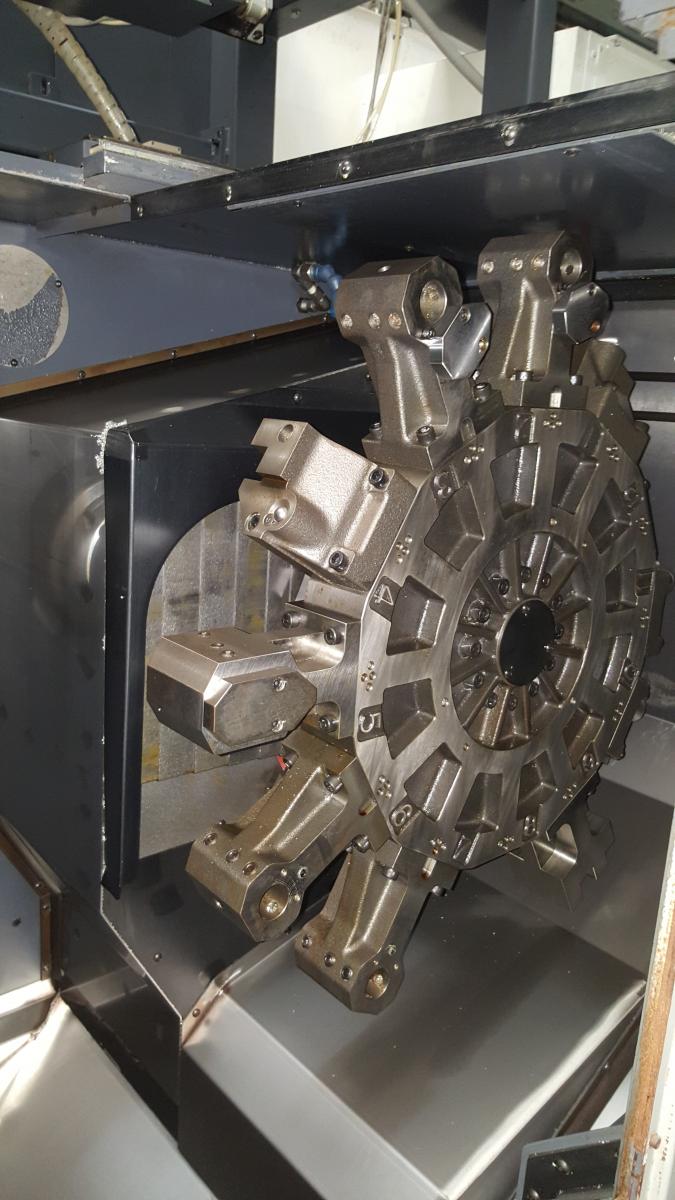

12-Position turret tool stations

Filtration conveyor system

Rear discharge chip conveyor

Dual spindles

Machine hours: 2100 Hours

FANUC Oi-TD control

Maximum spindle speed: 2220 RPM

Spindle motors: 15 HP

Marpos P7me electronic measuring system

Gantry robot

10-Pallet work stocker

Accesories:

OP 10:

Coolant thru spindle for op 20

FUJI Ball CB-8

Top jaw

Locator

(4) Boring bar tool holders

Stick tool holder

Drill tool holder

Robot jaw and pusher

OP 20:

FUJI ID collet

Collet

Locator with air confirmation

(7) Stick tool holders

Parts seating air confirmation OP 20

Inlet rotary work stocker

Conveyor

Unidad de medicion

Machine specification:

Recommended work size: φ300 x 150

Spindle diameter: φ120

Spindle bore: φ67

Spindle motor: 15/18.5

Turret index time sec: 0.41

Turret mechanism: Cam

Chuck size inch: 10-12

CNC Control: FANUC Oi-TD

Slide stroke:

X-axis: 195 [7.7]

Z-Axis: 315 [12.4]

Feed motor:

X-axis: 1.8 [2.4]

Z-Axis: 1.8 [2.4]

Robot specification:

Robot: LX-30B

Carrying capacity: 15+15

Robot controller: Maximum SP1

Machine size:

Footprint: 2720 x 2380

2013 vintage.

FUJI CSD-400 is a rotary transfer machine designed for high-precision machining applications in a wide range of industries. It features a 4-axis machining operation that carries out complicated workpiece machining in one setup. Its double-turret configuration offers greater flexibility and productivity compared to single-turret horizontal machining centers. Furthermore, an RS232C interface provides easy interfacing with CNC, robots, and other production equipment. The machine has a cast iron structure which ensures maximum rigidity and stability during machining. Its main spindle is driven by a 22/25 kW motor, providing top speeds of up to 8,000 rpm for precise and high-precision machining. Moreover, the spindle is equipped with auto-search function, which can be preset to automatically adjust the speed to the optimal level for each operation. The machine's tool magazine includes up to 64 tools, making it suitable for a wide range of operations. CSD-400 is equipped with an 8-position turret, allowing for regular and complex operations to be completed quickly and accurately. It features direct-drive motors for indexing and cross-slide, which offer more accurate and faster indexing compared to conventional spindle motor drive. Furthermore, the machine has a high-speed synchronous tapping function, allowing for quick and accurate cuts. FUJI CSD-400 also incorporates a highly convenient and efficient work exchange system, which allows for the quick switching of pallets. This reduces production downtime and increases production cycle time. In addition, the machine has a 25-position parts catcher that has an independent motorized cover allowing the operator to quickly switch between the catcher and manual loading. In terms of performance, CSD-400 has a number of features to ensure smooth and precise machining. It has a rapid traverse speed of 12m/min, with a minimum feedrate of 0.001mm/min. It further features an automatic backlash compensation system, ensuring accuracy regardless of material and machining speed. Furthermore, a 9-point positioning system is built in, providing steady and precise positioning for heavy cutting. Overall, FUJI CSD-400 is a robust and reliable machine tool for high-precision machining operations. It has a compact and flexible design, allowing it to fit into any production environment. Moreover, it features a wide range of features that make it suitable for a variety of applications.

There are no reviews yet