Used GIDDINGS & LEWIS 360-P #165267 for sale

URL successfully copied!

Tap to zoom

ID: 165267

Wafer Size: 6"

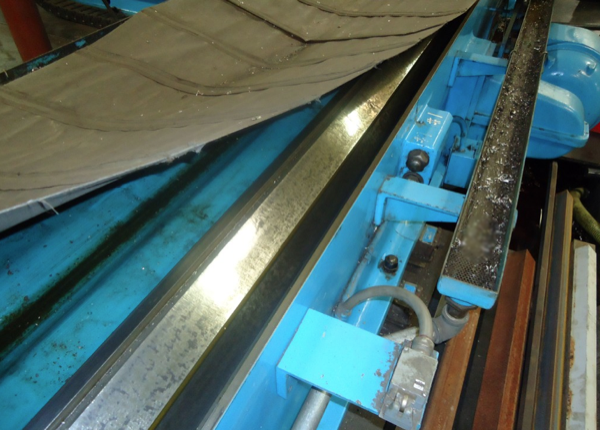

Planer-type boring mill, 6"

Specifications:

Nitralloy main spinde: 6" DIAMETER # 7 MORSE TAPER

Continuous feed: 48"

Nitralloy high speed spindle: 2" diameter, # 4 morse taper

Continuous feed: 9"

Vertical headstock travel: 96"

Column travel horizonal in & out: 36"

Table cross travel: 240"

Table working surface: 60" X 276"

Rapid travel of head stock and table: 120" IPM

Rapid travel of column: 60" IPM

36 Spindle speeds:

Low range: 3.13 - 187.5 RPM

High range on 6" spindle: 25 - 375 RPM

36 Spindle speeds:

Low range: 12.5 - 750 RPM

High range on 2" high speed spindle: 25 - 1500 RPM

18 feed ranges:

Low to headstock & column: 25 - 12.5 IPM

High to 18 feed ranges: 5 - 25 IPM to table

Headstock motor: 900/1800 RPM / 7-1/2/15 HP

Table drive motor: 1200 RPM / 20 HP

Power: 440 V / 3 PH / 60 HZ.

GIDDINGS & LEWIS 360-P is an advanced multitasking machining center designed to meet the production needs of a variety of industries. Its rigid construction and open design allow for easy integration into automated systems and it offers excellent levels of precision and repeatability. 360-P is equipped with a heavy-duty, dual-lever bed that is capable of carrying and positioning up to 7200 pounds (3,630 kg) and can be fitted with several types of workholding fixtures. It is configured with a heavy-duty column and base, allowing for longer travels and larger cutting capacities. The X-axis is capable of making strokes up to 560 inches (14,224 mm), and the Y-axis can move up to 480 inches (12,192 mm). The column and base design also provide a heavy-duty structure to keep the machine stable and rigid during long and heavy machining cycles. GIDDINGS & LEWIS 360-P is powered by two spindle units that are driven by two CNC-controlled AC servo motors. The spindles feature direct-driven 24000-rpm brushless type and low-inertia for high-speed machining. The spindles allow for a tool length offset adjustment, and the machine can be fitted with up to 30 tools. The spindles also feature a torque control equipment for heavier cuts, and a spindle lubrication system for reduced maintenance. The table features a high-pressure, high-torque, infinitely variable control unit and a variety of optional configurations. The large, rigid cast iron table is one-piece and offers a T-slot design with a maximum clearance of 9.8 inches (250mm). The machine table is also equipped with an electro-mechanical clamping machine, allowing for automated clamping of multiple pieces. The table can be fitted with various additional features, such as a digital readout, retractable powered chips conveyor, and chip-removal bucket. 360-P machine tool also offers an intuitive control tool, which is equipped with a multi-visor and LCD touch screen, providing machine operation and monitoring in a single step. The control asset also offers a range of options for quick programing, machine diagnostics, and troubleshooting. Overall, GIDDINGS & LEWIS 360-P is an advanced, heavy-duty machining center that provides high-quality, precise results. It is equipped with a variety of features, ensuring an efficient and flexible production process for a wide range of applications. The machine's robust construction, excellent precision, and advanced control model make it the perfect choice for manufacturers looking for maximum production flexibility and quality.

There are no reviews yet