Used GIDDLINGS & LEWIS PC-50 #182924 for sale

URL successfully copied!

Tap to zoom

ID: 182924

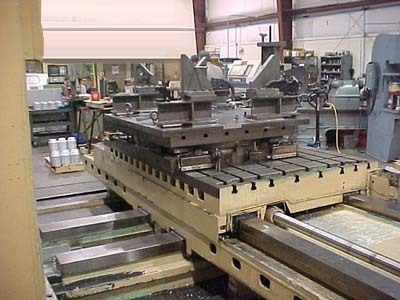

CNC Table-Type Horizontal Boring Mill

Diameter of Spindle: 5"

Working Surface of Table: 60" x 96"

Weight Capacity on Table: 30,000 Lbs.

Table Travel Cross: 96"

- Longitudinal: 42"

Vertical Travel of Headstock: 72"

Spindle Travel: 36"

Feeds: 0.1" 100" / Min.

Rapid Traverse Rate: 300" / Min. (X- & Y-Axes) / 200" / Min. (W- & Z-Axes)

Spindle Speeds: 25 1120 RPM

Spindle Taper: CAT 50

Motor: 30 HP 3/60

Equipped With:

MachineMate CNC Controls (Retro-Fit 2004) with the following features:

12.4" Color Touch Screen

Manual Pulse Generator

Operation Joystick for Axes Movement

Tool Management Software / Probe Logic Software / Adaptive Look-Ahead Software

Parallel Axes Function

Adaptice Ari II Command Filter

Automatic Drift Compensation / Machine Axis Error Compensation

Floppy Disk Drive

48" x 48" Giddings & Lewis Hydrostatic Rotary Table

Flood Coolant System / Lubri-Cool System

Electric Servo Drives (Double Reduction) / New Baldor Spindle Drive

Hardened Ways on Bed and Saddle / Non-Metallic Way Liners

Ball Screws on All Axes

1981 vintage.

The Giddings & Lewis GIDDLINGS & LEWIS PC-50 is a machine tool which is designed to deliver maximum performance and accuracy while providing reliable and consistent operation. It is a high-powered, and highly-competitive CNC turning center designed to meet the needs of any and all production facilities. PC-50 boasts a full-range of turning capability and state-of-the-art machine interface. GIDDLINGS & LEWIS PC-50 uses cutting-edge and innovative machining technology, making it perfect for operations needing increased flexibility, accuracy and productivity. For precision CNC turning applications, PC-50 delivers a powerful combination of maximum axis motion and cutting speed through its technologically advanced features. This machine tool features a 19-inch spindle for high-speed machining, with a rapid traverse rate of up to 9,000 rpm, and a spindle nose diameter of 4.75 in for maximum tool holding. GIDDLINGS & LEWIS PC-50 also has a robust bed structure to minimize vibration, that is stiff and vibration damping to ensure maximum performance and consistent accuracy. With PC-50, Giddings & Lewis utilizes innovative and multi-tasking capability to reduce idle time within its high-end CNC axes. This machine tool provides maximum machining flexibility, perfect for high-precision and large-volume machining requirements. GIDDLINGS & LEWIS PC-50's X- and Z-axis can process parts up to 3.2 inches in diameter and up to 18 inches long. Further, its spindle speed ranges from 0 to 20,000 rpm with its high-speed indexing capability helping deliver enhanced part accuracy. PC-50 also offers a broad range of options, accessories, and attachments to improve machining performance. Its advanced features include a high-performance 8-tool rotary magazine turret for quick toolling changes; a touchscreen control for easy programming access; and flexible, open architecture software for improved responsiveness. By taking advantage of GIDDLINGS & LEWIS PC-50's full range of features, machines operators can achieve higher levels of accuracy and speed. Thanks to the Giddings & Lewis PC-50, operators now have access to one of the most reliable and highly-functioning machine tools available on the market today.

There are no reviews yet