Used GILDEMEISTER CTX 200 S2 V1 #9093130 for sale

URL successfully copied!

Tap to zoom

ID: 9093130

Vintage: 1995

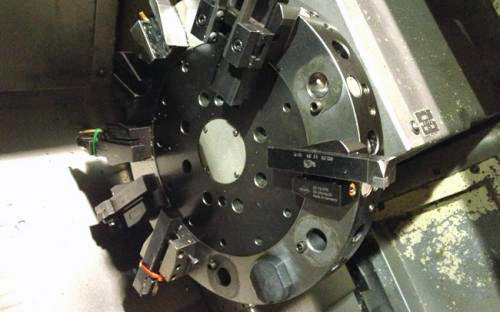

CNC Lathe

Chuck Size 5.5"

Max Diameter Bar Capacity 1.65"

Max Swing Over Bed / Carriage 17.34" / 8.27"

Max Turning Diameter 7.4"

Max Machining Length 13.7"

Tools 12

Spindle Speed 25 - 5000 RPM

Spindle Bore 2.2"

Spindle Nose A2-6

Spindle Motor 18 HP

X-Axis Travel 6.2"

Z-Axis Travel 13.79"

CNC Control: GE FANUC 0T

9" Monochrome CRT

RS232 Interface

Chip Conveyor (Side Exit)

Chucker (No Tailstock)

1995 vintage.

GILDEMEISTER CTX 200 S2 V1 is a machine tool designed for high precision machining applications. It is equipped with a 16-axis CNC control system that enables accurate and repeatable cuts, while its cutting diameter of 200 mm makes it suitable for a range of sizes and shapes. CTX 200 S2 V1 features an extended Z-axis of 1050 mm, allowing it to reach depths on particularly large workpieces. The machine is equipped with two high-speed spindles that allow simultaneous drilling and milling operations, as well as tapping and other operations. It boasts an impressive spindle speed of up to 18,000 rpm, a torque range of 690 Nm, and a maximum metal-removal rate of 90 cm³/min. GILDEMEISTER CTX 200 S2 V1 is configured with an automatic tool changer (ATC) that allows for quick and easy switching between tools. It also features an intuitive HMI interface, making it simple for operators to set up, adjust, and monitor the status of the machine. With its high-precision spindles, CTX 200 S2 V1 is capable of producing precise internal and external surfaces. Additionally, GILDEMEISTER CTX 200 S2 V1's rigid construction features a hardened meehanite cast iron base, a vibration-damping machine bed, and a heat-treating table, all of which work together to minimize vibrations. This allows the machine to produce highly accurate components in a variety of materials. CTX 200 S2 V1 is a reliable and versatile machine tool that is well suited to companies and workshops requiring high-precision machining capabilities. Its accurate and repeatable cutting duration combined with an extended Z-axis and intuitive HMI interface make it perfect for a range of production items. It is also highly suitable for machining complex geometries and small and intricate components.

There are no reviews yet