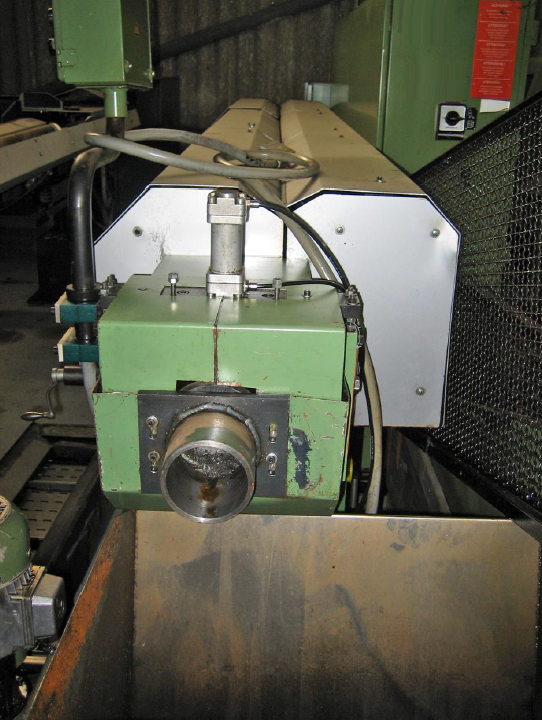

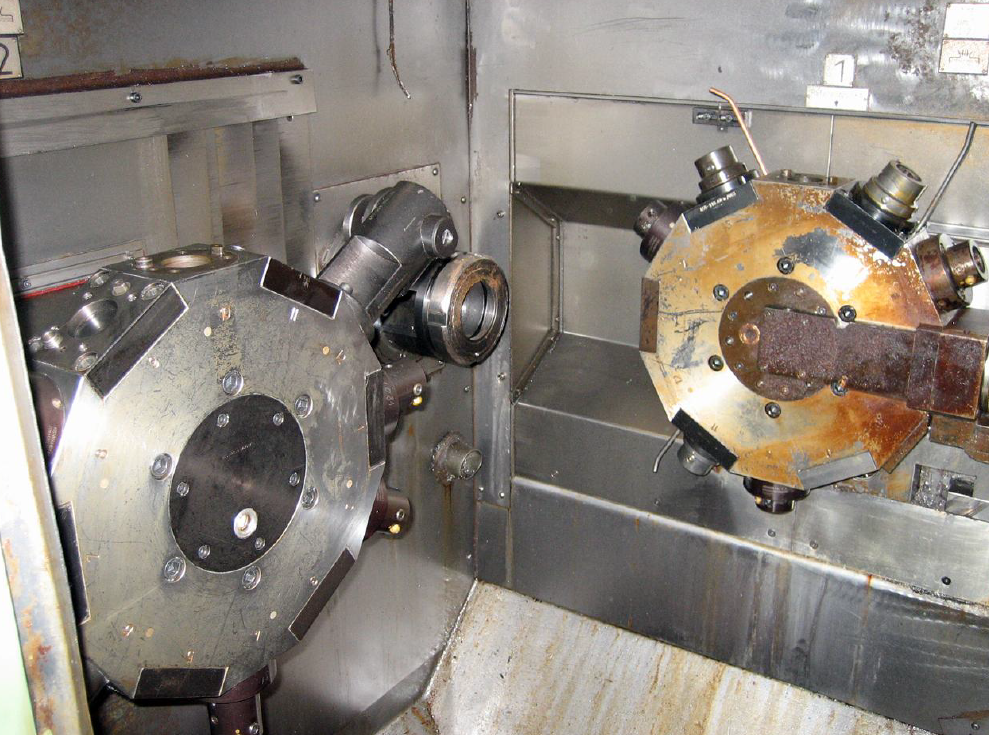

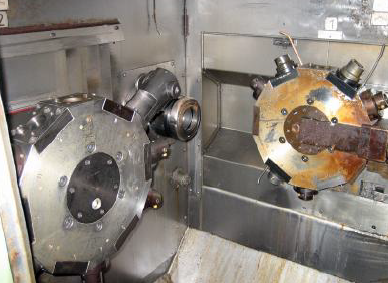

Used GILDEMEISTER GDM 65-4A #113108 for sale

URL successfully copied!

Tap to zoom

ID: 113108

Vintage: 1987

CNC Automatic Lathe

Max. turning diameter: 185 mm

Turning length: 450 mm

Internal spindle diameter: 65 mm

Spindle speeds: from 25 rpm up to 4000 rpm

Turret slide: number: 2

Feeds: up to 5000 mm/min

Rapid traverse:

Z axis (longitudinal travel): 15000 mm/min

X axis (transversal): 15000 mm/min

Voltage 50 Hz 3x: 380 Volt

Spindle motor: 22/29 kW

Various accessories:

Bar feeder FMB mini-turbo 3000/1700 LKMI

Chip conveyor

1987 vintage.

GILDEMEISTER GDM 65-4A is a multi-axis, high-precision workstation designed for complex milling and machining tasks. The machine features advanced sliding column technology and is commonly deployed in the automotive, aerospace and power generation industries. GDM 65-4A offers a range of innovative features, including a precision spindle and a comprehensive control panel. GILDEMEISTER GDM 65-4A's sliding column consists of a highly rigid steel construction that ensures smooth operation and precise machining. The sliding column features a sturdy box construction and a traveling cross beam with a 4800 mm stroke. This enables users to complete machining jobs with minimal vibration and with maximum accuracy. The spindle is made of high-grade, heat-treated and hardened steel, fitted with double-row angular contact bearings. This spindle delivers a maximum speed of 13,000 rpm and an accuracy of ±0.005 mm. The machine's comprehensive control panel is designed for efficient operation. It incorporates a 15" touch screen, giving users access to all necessary functions such as feed rate and settings for various axes. The programmable controller of GDM 65-4A enables experienced engineers to create customized commands for more precise tasks. The machine also supports Ethernet communication and automatic tool-changer functions. The machine is equipped with four linear and three rotary axes, as well as three spindles which can be dynamically positioned with a variety of tools. This enables GILDEMEISTER GDM 65-4A to handle complex machining jobs. The workstation can perform a variety of operations such as drilling, boring, threading, and slotting with maximum efficiency. The adjustable clamping system takes care of accurate and secure attachment of components while the CNC-controlled feed system ensures precise and consistent cutting. GDM 65-4A is suitable for high-tech workpieces that require precise machining, such as the production of complex three-dimensional parts and shapes. The machine is capable of handling a wide range of materials, from titanium to plastics, and supports a variety of cutting processes. GILDEMEISTER GDM 65-4A is CE certified, ensuring compliance with safety and quality standards. It also comes with a two-year warranty.

There are no reviews yet