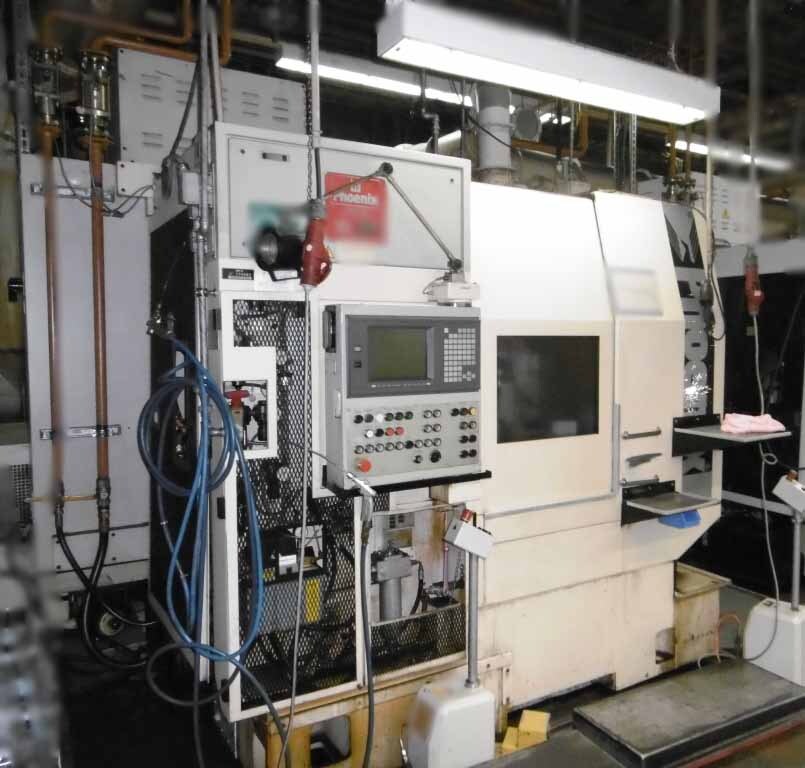

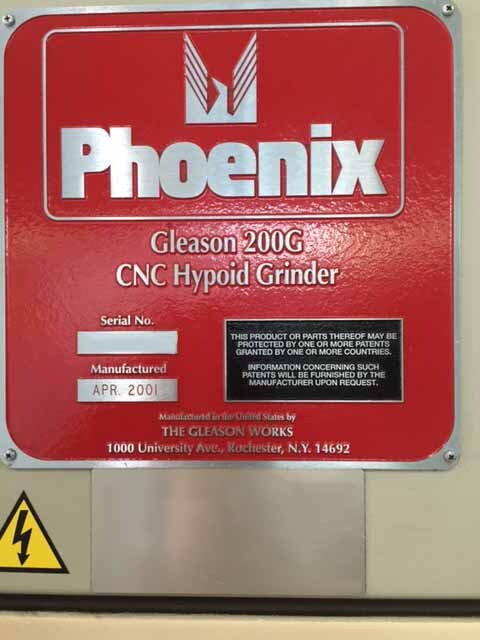

Used GLEASON 200 HG #9175210 for sale

URL successfully copied!

Tap to zoom

ID: 9175210

Vintage: 2001

Bevel gear grinding machine

Specifications:

Outer Ø of the workpiece: 215 mm

Number of teeth: 5 - 200

Tooth number ratio: 1:10

Grinding wheel Ø: 51-190 mm

Grinding wheel speed: 1.00 0 - 6.000 U/min

X Axis (Horizontal): 152 mm

Y Axis (Vertical): 178 mm

Z Axis: 304 mm

Sliding base travel: 2 "to 12"

B Axis: 3° - 90°

Spindle center end face: 115 mm

Axis speed: 125 mm/sec

Work piece speed: 0-30 min

Work piece spindle bore conical: 3 29/32"

Total power approx: 20 kW, 380 V, 50 Hz

FANUC: (7) Axes CNC controller type 160i CNC control

Currently warehoused

2001 vintag

GLEASON 200 HG is an advanced machine tool manufactured by GLEASON for the industrial production of curved and straight bevel gears. It enables the production of high-quality gears with excellent finish properties that are highly repeatable and consistent with precise dimensions. The machine is capable of automatically processing components up to 200mm in diameter, and features a continuously variable gear speed, allowing high cutting speeds without compromising the machined surface quality and finish. The GH200 consists of a base structure, a rotary table, a vertical travel equipment for the grinding head, a rapid driving unit for rough grinding, and a driven tandem grinding system allowing for very short cycle times. The machine is fitted with a pneumatically-actuated rotating head, which enables the precise grinding of gears with variable angles and profiles. The combination of a robust construction, an ergonomic ease of use, and the advanced control unit makes the GH200 a highly productive CNC grinding machine capable of extremely accurate parts. In addition, the machine is equipped with GLEASON "offline" gear shaping machine, allowing for the automated production of single- or double-profile bevel gears. The tool automatically compensates for pitched diameter errors, lead error, and involute errors, thus allowing for even more accurate gear shapes. Furthermore, the machine allows for the integration of automated loading and unloading systems, allowing for autonomous and unmanned production of gears. Designed to meet the highest production quality standards, the GH200 features a fully enclosed body and an advanced dust control asset, which minimizes the abrasive dust generated during the machining process. The machine has the capability to operate in wet or dry conditions, and its control model facilitates the integration of advanced optimization algorithms to reduce production times and increase the accuracy of the parts. Overall, 200 HG is an advanced machine tool capable of producing nut formers, spiral bevel gears, hypoid gears, scallop and harden & grind gears with high precision in minimal time. Its advanced control equipment, industry-leading technologies and ergonomically designed features make the GH200 a highly efficient and productive solution for demanding applications.

There are no reviews yet