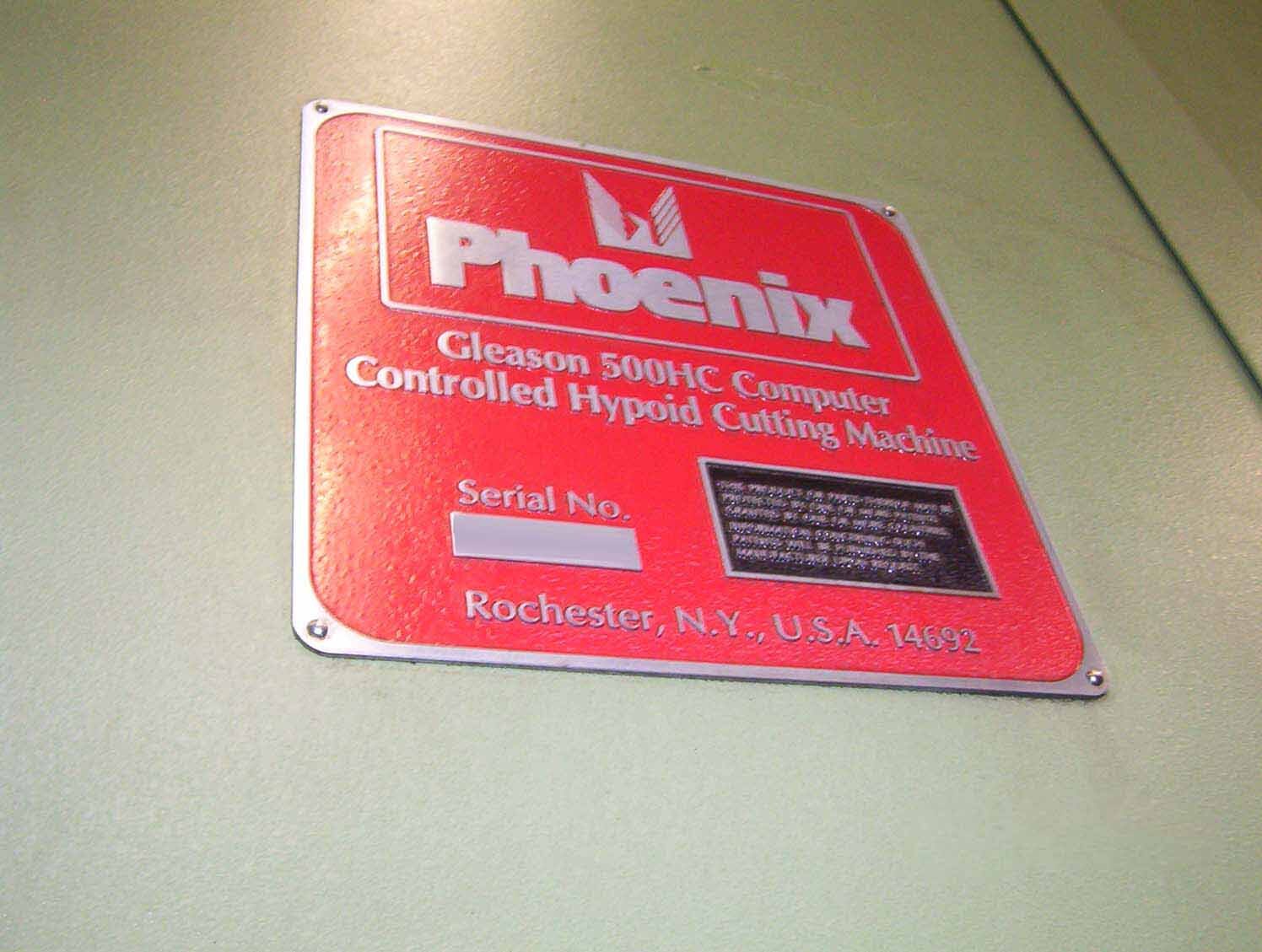

Used GLEASON 500 HC #175724 for sale

URL successfully copied!

Tap to zoom

ID: 175724

Vintage: 1994

CNC Bevel gear generator

Workpiece diameter: 762 mm

Controller: GE FANUC Series 150 M

Specifications:

Wheel diameter: Max. 762 mm

Face width: Max. 116,0 mm

Extreme ratio: 10:1

Number of teeth: 5 - 200

Axes:

Work spindle: 0-333 min

Swinging base: -3/90 °, 0-30°/sec

Tool head: 0 - 240 min

Horizontal: -305/+305 mm, 0-80 mm/sec

Vertical: -305/+305 mm, 0-80 mm/sec

Work piece slide: -25/+635 mm, 0-80 mm/sec

Currently warehoused

1994 vintag

GLEASON 500 HC is a machine tool designed for producing highly accurate cylindrical gear teeth using the hobbing process. 500 HC is built on the successful 500 platform, and utilizes precision-cut roller bearings, a spare gearbox design, and a heavy-duty coolant filtration equipment to deliver superior results. GLEASON 500 HC is capable of cutting straight, helical, bevel and face gears, as well as grinding them to ensure optimal performance and finishing. Its rugged, cast-iron structure ensures high rigidity and maximum dampening, which reduces vibration and improves cutting accuracy. The machine also features a hydrostatic spindle, which provides superior bearing lubrication and higher torques. 500 HC includes advanced hobbing technology including EC (feature-oriented) programming, multiple shifts, and programs that self-adjust to changing conditions. This ensures the highest precision and repeatability, even on difficult jobs. GLEASON 500 HC also has an onboard fan-cooled, high-performance inverter with advanced controls for maximum power. 500 HC is designed with a number of operator-friendly features, including a large touchscreen control interface and an ergonomically designed operator's station with adjustable lighting and air purification. The machine has a powerful CNC system and fully automatic cycle start/stop mechanisms, allowing for automated production. GLEASON 500 HC is designed for heavy-duty industrial use, and with its durable construction, enhanced servo motor and AC spindle motors, can withstand long runtimes and handle larger payloads. The machine also features an advanced balance unit to reduce vibration, which helps to improve chip load distribution and cutting accuracy. 500 HC utilizes top-of-the-line cutting and grinding tools, resulting in higher quality parts and reduced downtime. Its high-speed, large-diameter thru-spindle coolant ensures optimal cutting conditions and tool life, while its world-class tailstock machine simplifies set-up and reduces cycle times. GLEASON 500 HC is a versatile, reliable, and efficient machine tool for producing the highest quality parts. With its advanced cutting and grinding capabilities and its rugged design, it will bring your production process to the next level.

There are no reviews yet