Used GLEASON Phoenix 175 HC #9397428 for sale

URL successfully copied!

Tap to zoom

ID: 9397428

Vintage: 1997

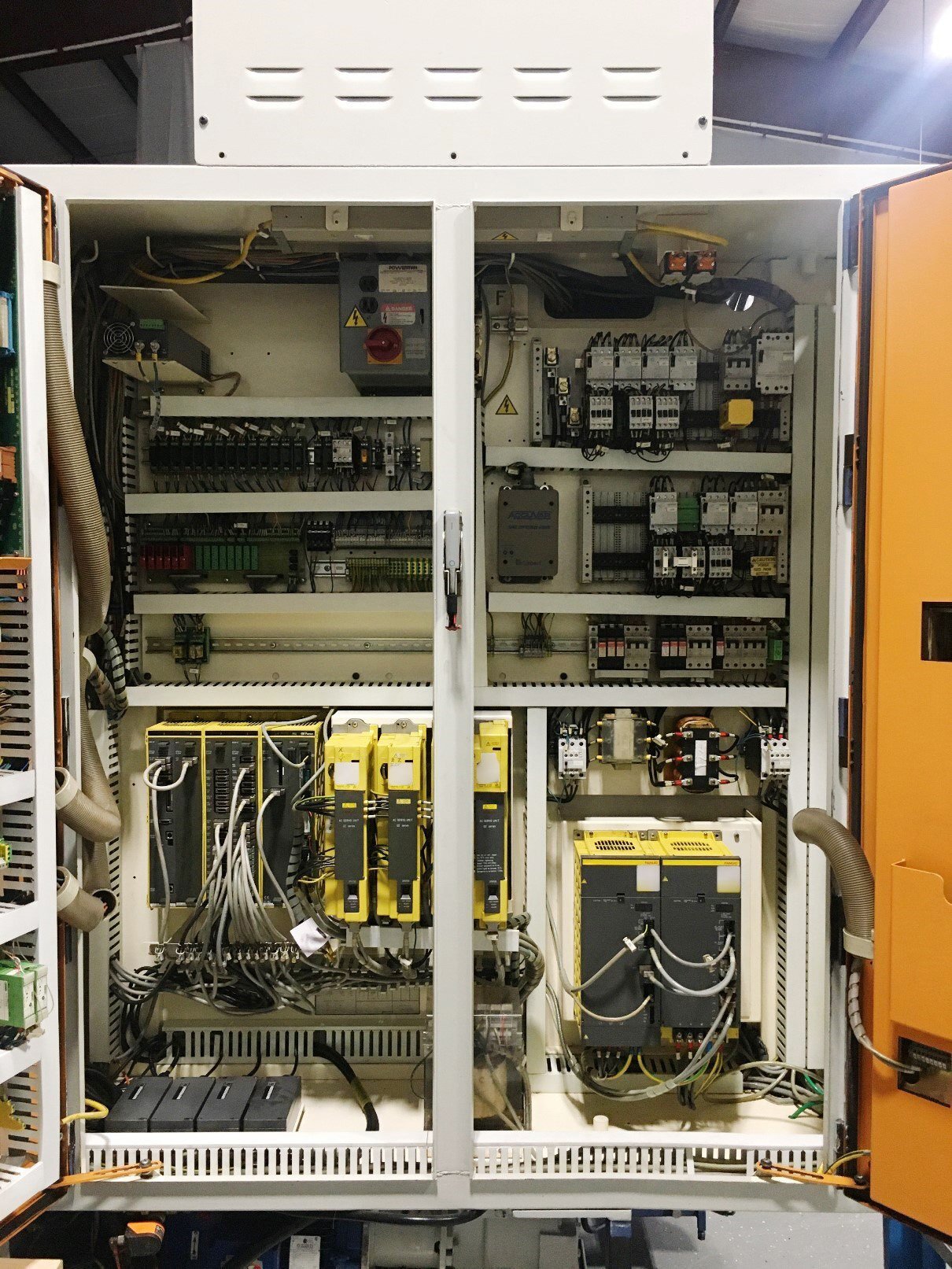

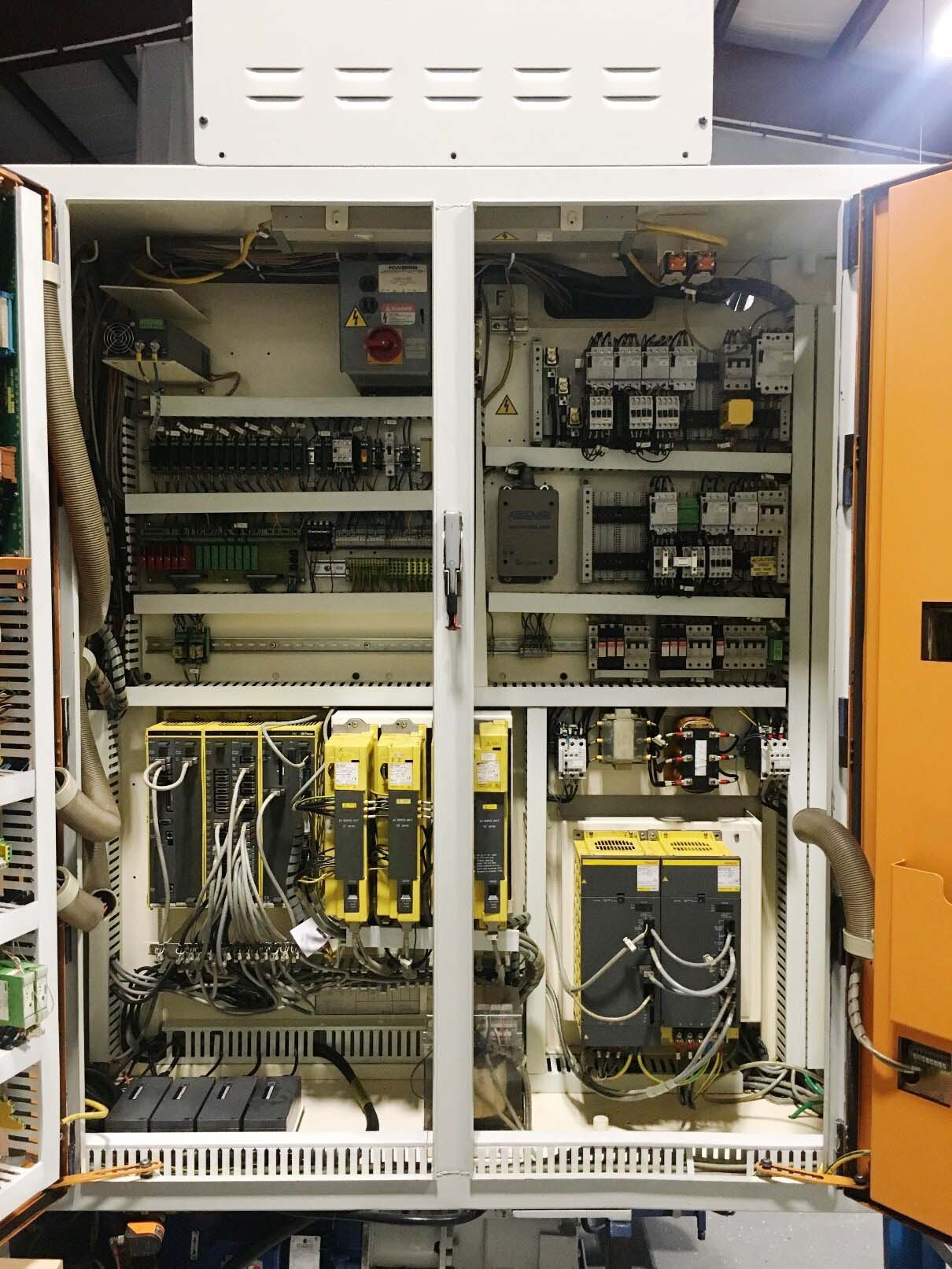

CNC Hypoid cutting machine

GE-FANUC 150 MB CNC Controller

Speed cutter spindle: 30 to 500 RPM

With coolant system

Speed worktable:

Face milling: 0-75 RPM

Face hobbing: 0-375 RPM

Magnetic chip conveyor

LCD Flat color display, 10.4"

Cycle fault monitoring

Production and sharpen-cutter count display

Hydraulic work-piece chuck (With draw-rod and nut)

Work spindle bore: 3-29/32

Work-head ratio gears: 5:1

Single-cycle gear finishing arrangement

Work chamber lighting

Foot switch for hydraulic chucking of work-piece

Power forced lubrication system

Self contained coolant system (Pump tank and piping)

Magnetic chip separator: Chip exit height, 24"

Control circuit: 115 VAC, 24 VDC (Input / Output)

PHOENIX NFPA 79-1987

Storage capacity for (100) Parts

Security key for control of set-up

Machine documentation

Wiring and hydraulic diagram

Extreme ratio: 10:1

Root angle range (B-Axis): -5° to 90°

Equivalent root angle range: -5° to 90°

Maximum gear pitch diameter: Face hobbing

Spiral: 30°

TRI-AC Cutter, 6" with (13) blade groups

Maximum pitch diameter:

1:1: 6.000"

2:1: 7.500"

5:1: 7.500"

Maximum full depth: 0.550"

Maximum face width: 1.600"

Maximum gear pitch diameter: Face milling

Spiral: 35°

Diameter cutter, 7.5"

Maximum pitch diameter:

1:1: 6.750"

2:1: 8.500"

5:1: 8.500"

Maximum full depth: 0.625"

Maximum face width: 1.600"

Maximum swinging base travel (B-Axis): 5° to 90°

Maximum vertical travel (Y-Axis): -4.00" to 7.00"

Maximum horizontal travel (X-Axis): -6.00" to 4.00"

Sliding base travel (Z-Axis): 2.00" to 12.00"

Machine center to work spindle face: 4.500"

Tooth number: 5 to 200

Cutter diameters:

Conventional face milling: 1.1" to 7.5"

HELIXACT

TRI-ACT

Fine pitch: 4.01-5.98"

Coarse pitch: 5.98"

Speed:

B-Axis swinging base (Degrees per second): 30°/Sec

A-Axis work spindle (Face milling): 0-75 RPM

A-Axis work spindle (Face hobbing): 0-375 RPM

C-Axis cutter spindle: 30-500 RPM

X-Axis horizontal: 4.92"/Sec

Y-Axis vertical: 4.92"/Sec

Z-Axis sliding base: 4.92"/Sec

Work spindle:

Diameter of taper at large end: 3-29"/32"

Taper per foot: 38"/64"

Depth of taper: 3"

Motors:

B-Axis swinging base: FANUC 5s/3000 Digital servo-drive, 2,000 RPM

A-Axis work spindle (Face milling): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

A-Axis work spindle (Face hobbing): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

X-Axis horizontal: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

Y-Axis vertical: FANUC 5s/3000 Digital servo-drive, 10,000 RPM with brake

Z-Axis sliding base: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

C-Axis cutter spindle: FANUC 1024 15P Digital servo-drive

Coolant: 3 HP

Hydraulic: 3HP

Chiller

Chip separator

Control circuit: 115 VAC with 24 VDC Input / Output

Power supply: 380-460 V, 50/60 Hz, 3-Phase

1997 vintage.

GLEASON Phoenix 175 HC is a CNC machine tool manufactured by GLEASON Corporation. It is a highly efficient grinding and honing machine for complex cylindrical and spherical parts, and is able to handle parts of up to 8in. diameter and 18in. length. The Phoenix 175 is designed to help reduce cycle time and reduce material waste. It allows for high-precision parts production and is capable of producing tight tolerance parts. The Phoenix 175 has a variety of features, including a FANUC 0i-TD CNC controller, X/Y/Z travel of 11" x 8.5" x 8.5", a maximum spindle speed of 10,000 RPM, a 0.0001" resolution, a 6" 3-jaw chuck, a heavy-duty honing spindle with an adjustable honing pressure up to 50Kg, and a hydrostatic spindle for grinding with a feed rate of up to 5 m/min (1654 ft/min). The machine's grinding spindle supports diamond and CBN grinding wheels from 8mm to 85mm, and features a high-speed spindle with a digitally adjustable pressure control. The honing head rotates at speeds up to 4000 rpm, and can be easily cooled with coolant or oil. The Phoenix 175 also offers automatic tool changers, with up to 10 positions for grinding, honing, and reaming tools. The CNC controller features a PC-based user interface, with parameter entry and editing capabilities. The Phoenix 175 is ideal for grinding and honing modifications, such as double-taper, ovaling, cylindricity/roundness corrections, and simultaneous surface and/or in-feed honing. Highly complex, precision parts are easily produced with the Phoenix 175's spindle accuracy of up to 0.0005mm and repeatability of 0.001mm. The machine's robustness means that it is capable of handling job company applications and can perform a variety of metalcutting operations. Compact in design, the Phoenix 175 helps manufacturers reduce floor space while still allowing complete grinding and honing operations to be carried out efficiently. The machine is highly reliable, with proven performance and minimal downtime, ensuring maximum productivity.

There are no reviews yet