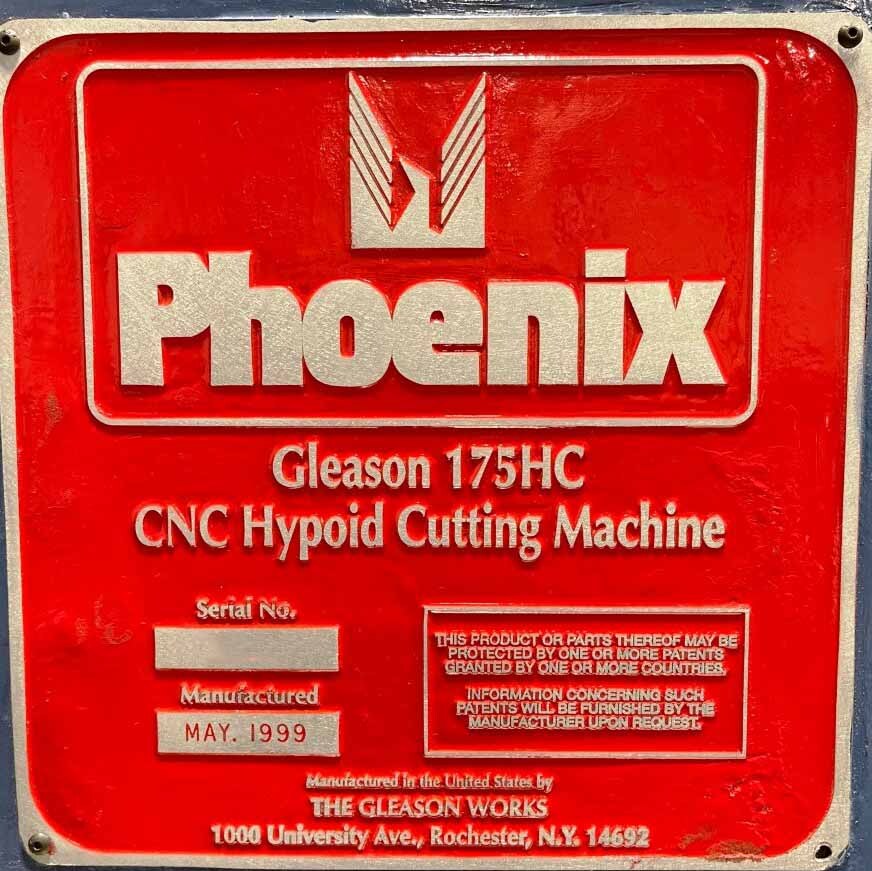

Used GLEASON Phoenix 175 HC #9410228 for sale

URL successfully copied!

Tap to zoom

ID: 9410228

Vintage: 1999

CNC Hypoid cutting machine

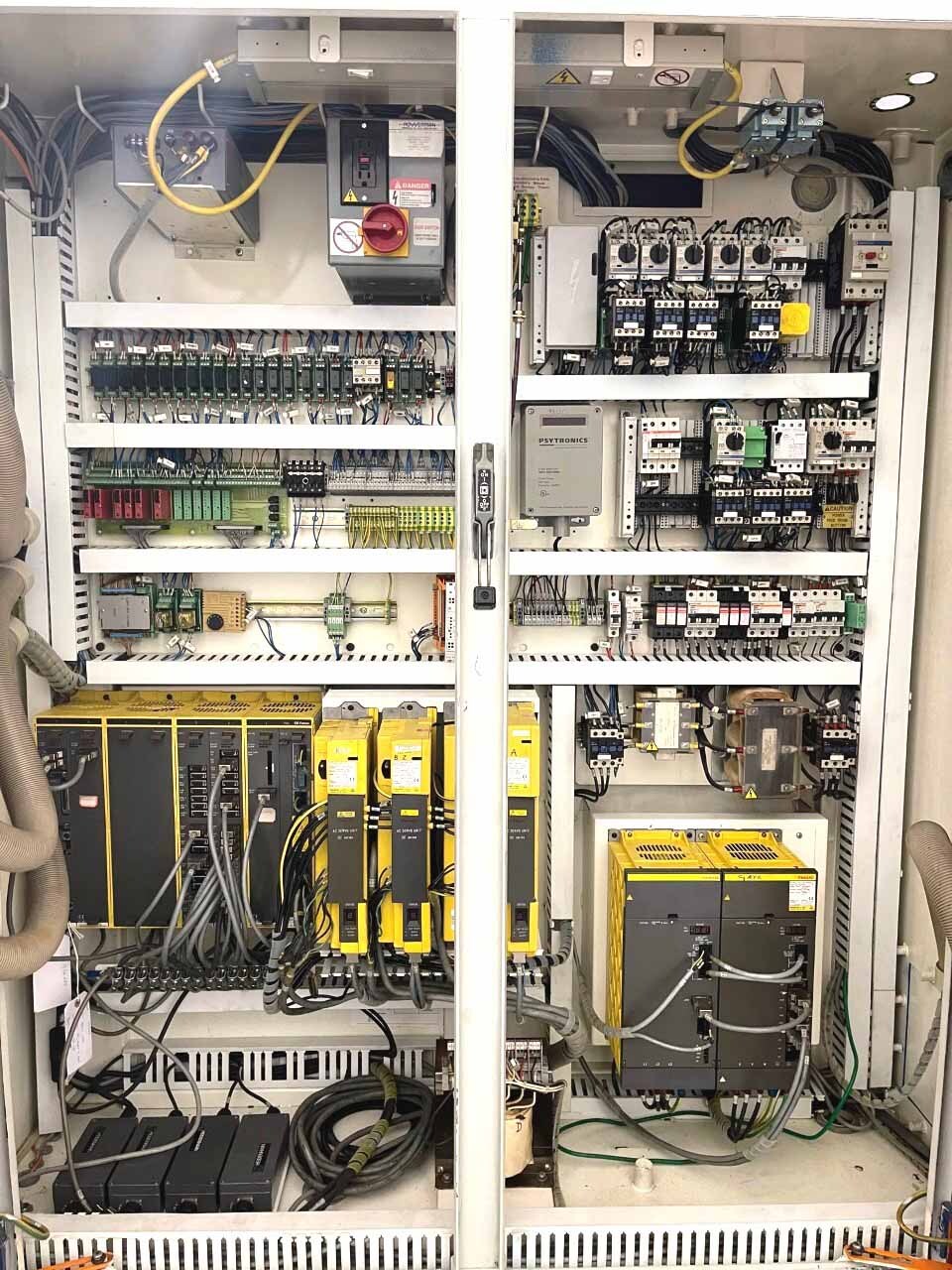

GE-FANUC 150 MB CNC Controller

High speed for dry cutting

Cyclovac air assist chip removal system

FANUC 60i Computer control

Face milling: 216 mm

Face hobbing: 190 mm

Magnetic chip conveyor

LCD Flat color display, 10.4"

Cycle fault monitoring

Production and sharpen-cutter count display

Hydraulic work-piece chuck (With draw-rod and nut)

Work spindle bore: 3-29/32

Work-head ratio gears: 5:1

Single-cycle gear finishing arrangement

Work chamber lighting

Foot switch for hydraulic chucking of work-piece

Power forced lubrication system

Self contained coolant system (Pump tank and piping)

Magnetic chip separator: Chip exit height, 24"

Control circuit: 115 VAC, 24 VDC (Input / Output)

PHOENIX NFPA 79-1987

Storage capacity for (100) Parts

Security key for control of set-up

Wiring and hydraulic diagram

Extreme ratio: 10:1

Root angle range (B-Axis): -5° to 90°

Equivalent root angle range: -5° to 90°

Maximum gear pitch diameter: Face hobbing

Spiral: 30°

TRI-AC Cutter, 6" with (13) blade groups

Maximum pitch diameter:

1:1: 6.000"

2:1: 7.500"

5:1: 7.500"

Maximum full depth: 0.550"

Maximum face width: 1.600"

Maximum gear pitch diameter: Face milling

Spiral: 35°

Diameter cutter, 7.5"

Maximum pitch diameter:

1:1: 6.750"

2:1: 8.500"

5:1: 8.500"

Maximum full depth: 0.625"

Maximum face width: 1.600"

Maximum swinging base travel (B-Axis): 5° to 90°

Maximum vertical travel (Y-Axis): -4.00" to 7.00"

Maximum horizontal travel (X-Axis): -6.00" to 4.00"

Sliding base travel (Z-Axis): 2.00" to 12.00"

Machine center to work spindle face: 4.500"

Tooth number: 5 to 200

Cutter diameters:

Conventional face milling: 1.1" to 7.5"

HELIXACT

TRI-ACT

Fine pitch: 102-152 mm

Coarse pitch: 152 mm

Speed:

B-Axis swinging base (Degrees per second): 30°/Sec

A-Axis work spindle (Face milling): 240-960 RPM

A-Axis work spindle (Face hobbing): 240-960 RPM

C-Axis cutter spindle: 380-910 RPM

X-Axis horizontal: 4.92"/Sec

Y-Axis vertical: 4.92"/Sec

Z-Axis sliding base: 4.92"/Sec

Work spindle:

Diameter of taper at large end: 3-29"/32"

Taper per foot: 38"/64"

Depth of taper: 3"

Motors:

B-Axis swinging base: FANUC 5s/3000 Digital servo-drive, 2,000 RPM

A-Axis work spindle (Face milling): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

A-Axis work spindle (Face hobbing): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

X-Axis horizontal: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

Y-Axis vertical: FANUC 5s/3000 Digital servo-drive, 10,000 RPM with brake

Z-Axis sliding base: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

C-Axis cutter spindle: FANUC 1024 15P Digital servo-drive

Coolant: 3 HP

Hydraulic: 3HP

Chiller

Chip separator

Manuals included

Control circuit: 115 VAC with 24 VDC Input / Output

Power supply: 380-460 V, 50/60 Hz, 3-Phase

1999 vintage.

GLEASON Phoenix 175 HC is a combination machine tool designed for both cut-and-form generating grinding of cylindrical and non-cylindrical workpieces. Phoenix 175 HC is a full-featured, versatile machine tool with a modular design for easy machine setup and ideal for a wide range of grinding and profile grinding applications. GLEASON Phoenix 175 HC's base machine is equipped with a high-capacity, direct-driven, CNC-controlled grinding spindle with a maximum cutting speed of 15.000rpm. The spindle is supported by powerful linear motors and a direct-drive servomotor guaranteeing precise positioning and reliable cutting speeds. The spindle can be adjusted in both the X and Z axes for maximum precision and surface-finish quality. Phoenix 175 HC's spindle drive motor is an advanced 5-HP 3-phase AC motor, directly driven along two parallel hardened and ground guide rails. The spindle drive includes a low-inertia, high-torque, belt-driven motor, allowing for precise motion control and ensuring consistent smooth cutting. The machine's grinding head is equipped with active front and rear positioners for rapid and repeatable cutting of complex geometries. The positioners are powered by a four-phase brushless DC motor, enabling high-accuracy, low-error profile grinding of even the most complicated shapes. GLEASON Phoenix 175 HC is supplied with a built-in grinding wheel that is driven by a two-speed AC motor. The spindle speed is adjustable to accommodate different grinding wheel diameters, allowing the machine to create multiple cutting profiles with a single setup. The machine is outfitted with a standard GLEASON controller with dial-in functions, an intuitive touch-screen operator interface, and encoder feedback, so that all machine functions can be programmed and performed with ease. Phoenix 175 HC is also constructed with an industrial-grade stainless steel casing and features durable components, including a precision-grade scrape-resistant liner plate and a full-coverage guard system. GLEASON Phoenix 175 HC is suitable for multiple cutting applications in a range of industries, including aerospace, automotive, shipbuilding, and military applications.

There are no reviews yet