Used GSM / GENESIS M-710iC / 20L #9251242 for sale

URL successfully copied!

Tap to zoom

ID: 9251242

Vintage: 2011

System

6-Axis robot

Horizontal reach: 122.4"

Repeatability: .0059"

(2) Stations work cell:

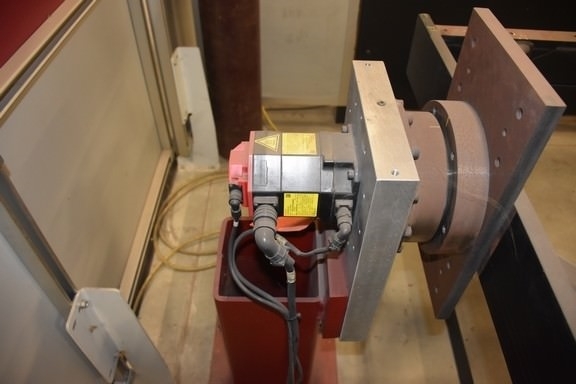

Head stock

Tail stock

Fixed Table

Equipped with:

GENESIS Robotic control system

FANUC R30IA Controller

LINCOLN Power wave i400 power supply

With weld interface

Tregaskiss 500-AMP air colled torch

GENESIS Torch alignment station

GENESIS Complete safety fencing: (2) Interlocking gates

Torch wire brake

Weld equipment pallet

AP Torch reamer with mister and wire snip unit

(2) Light guard barriers

Robot riser optimizes robot reach

Touch sensing option

2011 vintage.

GSM / GENESIS M-710iC / 20L is a fully automated 5-axis horizontal machining center from German machine tool builder, GSM. GSM M-710iC / 20L is an extremely versatile machine, capable of high-precision and complex machining of parts made from a wide range of materials, including aluminum, steel, titanium, and composites. The machine is designed to reduce setup and tool changing times and to increase productivity through automation. GENESIS M-710iC / 20L has a working envelope of 710mm (X-axis) x 600mm (Y-axis) x 500mm (Z-axis) with a travel speed of up to 20m/min. Its two main spindles are driven by a direct-drive motor, allowing for incredibly smooth rotation and providing outstanding performances in terms of speed, acceleration, and torque. The main spindle is mounted on a swivel head allowing for even smoother machining and allowing access to more complex detail. An additional B-axis tool head allows for 5-axis simultaneous machining with a total of 14 tool pockets for maximum flexibility. M-710iC / 20L is equipped with a Heidenhain TNC-620 dual-channel control system with a 15-inch touch-screen display. The Touch-Screen Display allows the operator to easily enter data and allows for easy monitoring of the machine's performance. With the addition of the optional barcode reader, GSM / GENESIS M-710iC / 20L is able to pull up data specific to each job, allowing for quick changes during production. Its flexible interface allows easy connection to external devices, such as CAD/CAM systems, as well as peripheral equipment for automated part-handling. Equipped with a variety of safety features, GSM M-710iC / 20L is engineered to help ensure the safety of the machine, the operator, and the production environment. These features include motion-sensing detectors that stop the machine in the event of an error or jam and a low-voltage door-safety switch that stops all machine movement when the door is opened. Designed for precision and productivity, GENESIS M-710iC / 20L is an ideal machine for multitasking shops that demand the highest levels of accuracy and speed. With its advanced features and innovative technology, M-710iC / 20L helps operators achieve peak performance in a variety of applications.

There are no reviews yet