Used HAAS HS-1R #9179199 for sale

URL successfully copied!

Tap to zoom

ID: 9179199

Vintage: 1994

CNC Horizontal machine center

HAAS 32 Bit

Specifications:

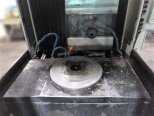

Table size: 18" Diameter

Table index: Built in rotary table

Maximum table load: 600 lbs

X-Axis travel: 24"

Y-Axis travel: 20"

Z-Axis travel: 22"

Spindle speeds: 0 - 7500 RPM

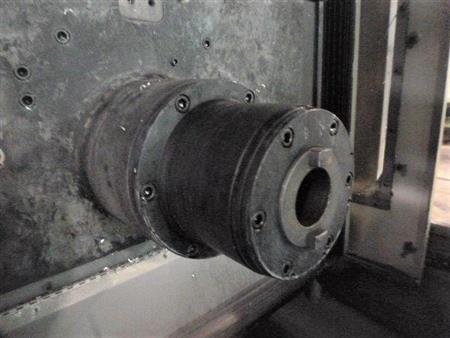

Spindle taper: CAT #40

Spindle torque: 250 ft / lbs @ 450

Spindle motor: 20 HP

Tool capacity: (24) Positions ATC

Maximum tool diameter / Weight: 3.5" / 12 lbs

Tool change time T to T / C to C: 8 sec. / 10 sec

Rapid traverse rates: 710 IPM

Machine dimensions without chip conveyor: 91" x 132" x 111"

Equiped with:

Single table design

Chip auger with chute

Coolant system with pan / Pump

(2) Speed geared transmissions

Manuals

1994 vintage.

HAAS HS-1R is one of the most reliable machine tools available on the market today. This high-performance Vertical Machining Center features a robust 60" x 14" work table and a 25 hp direct-drive spindle motor that is capable of producing high-precision parts in external and internal operations. Its self-contained HAAS Control features an intuitive, user-friendly interface that simplifies setup and operation, allowing for quick throughput times. In addition, its full contour machining capabilities, combined with a 30-tool Automatic Tool Changer, allow for fast and efficient production of a wide variety of complex parts. HS-1R boasts an impressive set of features, making it an excellent choice for high-volume machining. Its 12,000RPM spindle motor is capable of rapid traverse rates of up to 1050IPM, with 10° bi-directional tilt capability allowing for greater cutting flexibility. Also, its integrated-tool-loading equipment has a maximum tool length of 11" (279mm) and a 15" (380mm) tool diameter capacity. With a fully integrated 40-tool Automatic Tool Changer, and fast cycle times, this machine is able to maintain high output while maintaining close tolerance part quality. HAAS HS-1R utilizes an innovative dual-processor system to process the Advanced Programmable Logic Controllers (APLC) code, which is designed for efficient programming. It also offers Hi-G acceleration, delivering rapid traverse acceleration and improved productivity. In addition, HAAS control unit is equipped with built-in diagnostic capabilities, allowing the operator to quickly spot problems and quickly make adjustments. Built with advanced safety systems, HS-1R promotes a secure work environment for its operator. Its enclosure completely encloses the working area, and the front window is made of safety glass. This machine also features HAAS Dangerous-Axis bi-directional safety machine, providing a protective barrier between the operator and the moving components. HAAS HS-1R is an ideal machine for any company that needs precision machining, high productivity, and excellent safety capabilities. With its robust direct-drive spindle motor, high-speed traverse rates, and integrated 40-tool Automatic Tool Changer, HS-1R is a powerful and reliable choice for any production environment.

There are no reviews yet