Used HAAS TL-3W #9220744 for sale

URL successfully copied!

Tap to zoom

ID: 9220744

CNC Lathe machines

Maximum capacity: 30" x 60" (762 x 1524 mm)

2-Speed gearbox

Intuitive programming system

Program memory: 1 MB

Memory lock keyswitch

Color LCD monitor, 15"

USB Port

No workholding

Toolpost / Toolholders included

Swing diameter:

Over font apron: 30.0"

Over cross slide: 18.0"

Capacities:

Maximum cutting diameter: 30"

Maximum cutting length: 60"

Between centers: 60"

Travels & feedrates:

X-Axis: 16"

Z-Axis: 60"

Rapids on X: 75 in/min

Rapids on Z: 150 in/min

Maximum thrust X: 3096 lb

Maximum thrust Z: 3086 lb

Spindle:

Spindle nose: A2-6

Maximum rating: 30 Hp

Maximum speed: 1800 rpm

Maximum torque: 1600 ft-lb at 60 rpm

Spindle bore ø: 3.50"

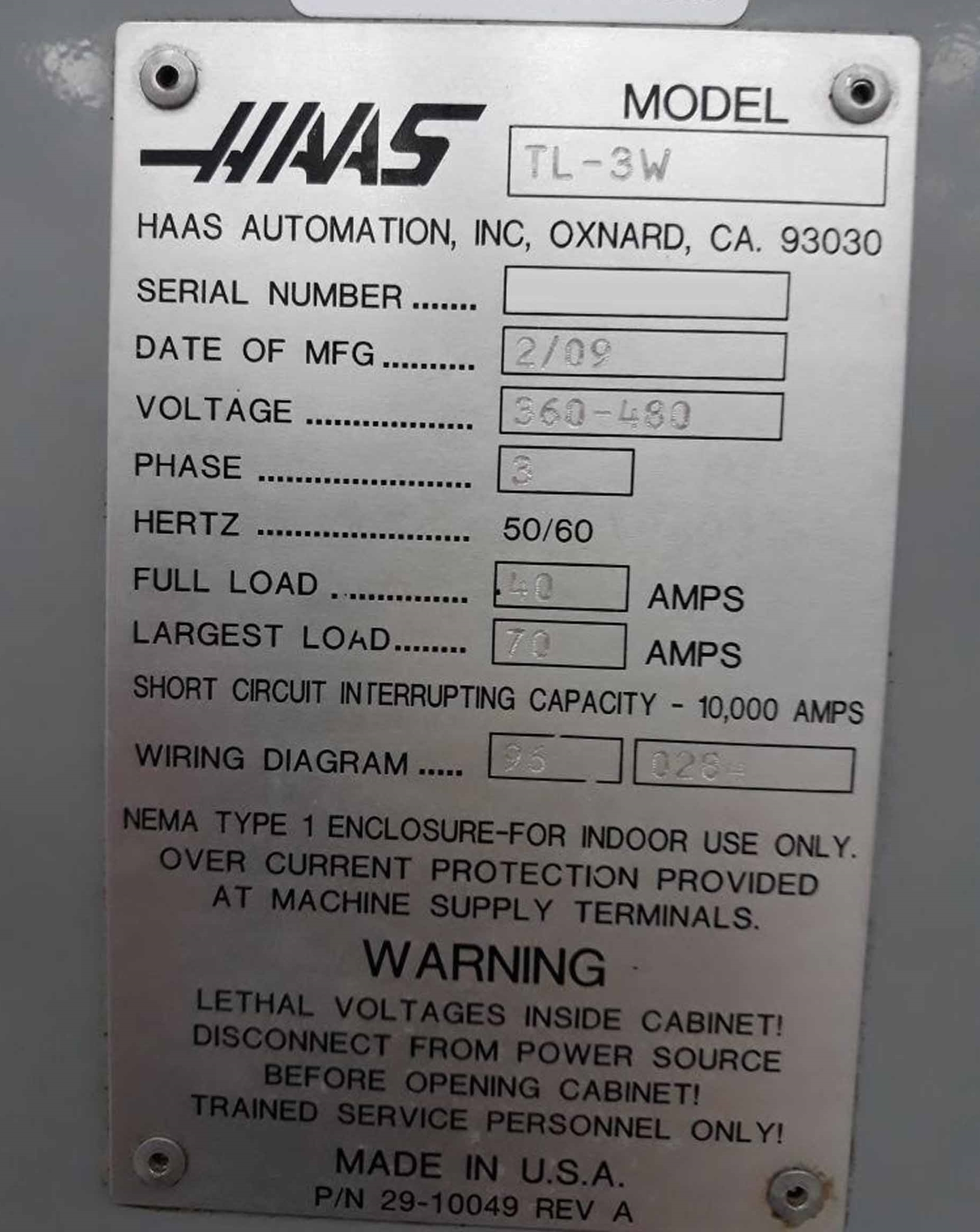

Power:

195-260 VAC, 100 A, 3-Phase

354-488 VAC, 50 A, 3-Phase

2009-2010 vintage.

HAAS TL-3W is a highly advanced CNC machine tool for precision turning. It has been designed to produce parts with extreme accuracy to tight tolerances with quality finishes. The machine is capable of producing parts up to Ø20 in diameter (50mm) and provides a maximum speed of 2,800RNPM and a turning capacity of up to 3.5in (89mm). Its rigid cast iron construction provides a stable turning platform and its 15HP vector drive enables the machine to dynamically adjust for increased speed and torque capability. The features of TL-3W include an 8-position servo-controlled turret with live tooling capability, a variable speed spindle, a swing arm robot, a full programmable coolant system, and a powerful yet intuitive HAAS CNC control. The servo-controlled turret with the live tooling capability makes the machine a perfect choice for high production parts by allowing quick and efficient indexing of tools and a greater range of machining applications. The variable speed spindle allows for improved finish on parts and can be adjusted from 0-2,800RP (revolutions per minute). The spindle is also equipped with a powerful Coolant Air Blast system for maximum cutting performance. HAAS control system is capable of running a variety of collet style tool holders and configured with either HAAS G99 Spindle Orientation or the Spindle Synchronous Orientation for last part clamping on right and left for complex contours. HAAS also provides an array of proprietary software that can be used for monitoring and diagnostics of the machine's operation, including HAAS Remote Jog Panel (HRTJ) and Tool Life Management. The swing arm robot is another excellent feature in HAAS TL-3W which provides automation for many of the manual operations of the machine and also of the manufacturing process. The robot is equipped with a 6-axis articulated arm that allows for flexibility and efficient production by quickly and accurately locating and locating operations spindles. TL-3W is an exceptional machine tool, offering powerful features and advanced capabilities. It is highly accurate and reliable, providing consistent quality parts with tight tolerances and excellent surface finishes. It is a great choice for any manufacturing company that requires precise and repeatable parts with high production rates.

There are no reviews yet