Used HAAS VF-2 #9277496 for sale

URL successfully copied!

Tap to zoom

ID: 9277496

Vintage: 1999

CNC Vertical machine center

Table size: 36" x 14"

X-Axis travel: 30"

Y-Axis travel: 16"

Z-Axis travel: 20"

Spindle speed: 0 - 7500: RPM

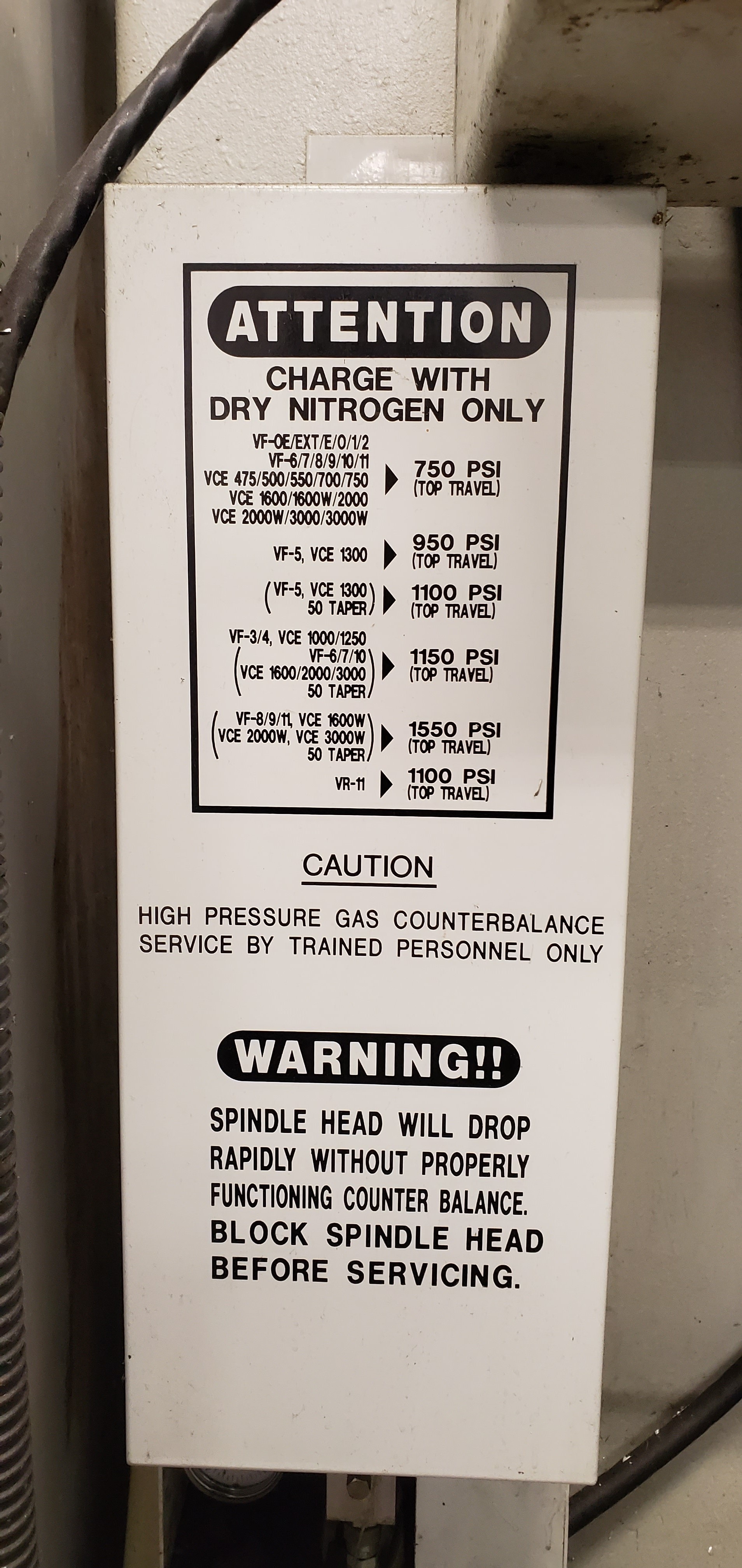

Spindle taper: CAT: 40

Spindle motor: 15 HP

Tool changer style: Umbrella

Tool changer positions: 20+1

Includes:

HAAS CNC Control

4th Axis HRT-210

Transmission

1999 vintage.

HAAS VF-2 is a high-performance machine tool designed and manufactured by HAAS Automation Company, one of the leading providers of machine tools. HAAS VF2 is a vertical machining center is designed to provide accurate and repeatable machining results. It has a powerful three-axis spindle capable of rapid travel and feed rates of up to 710 ipm (18.3 m/min) and a 20-hp (15-kW) vector drive with 20-tool capacity. The machine tools main structural components are a robust cast iron frame and Meehanite cast iron table providing exceptional rigidity. VF 2- differs from most machine tool by its onboard two-stage 24-tool carousel automatic tool changer, which allows for an uninterrupted production of components and allows for a quick exchange of tools. The rapid tool changer mechanism can be used for 20-tool and 24-tool applications, further enhancing the machine's speed and flexibility. VF-2 features a 12,000rpm spindle and is designed to efficiently cut steels, aluminum, titanium, exotics, and composites. The spindle is also equipped with C4-level internal and external coolant filtration, providing one-micron filtration for maximum chip evacuation and high-speed turning. The machine's advanced contouring capability comes from its distinctive motion control system, designed specifically for HAAS machines. This system produces accurate part profile from the smallest to the largest parts, up to 2000 ipm (50.8 m/min) traverse and 15000 rpm high-speed spindle. It accommodates roughing as well as production of contoured finishes with a 0.015mm incremental control in a slot finishing. HAAS VF 2 is also equipped with a HAAS intuitive graphical user interface (GUI), a programmable rotary table, easier program set-up and a color LCD monitor for easier run time diagnostics, coolant system, integrated machine spindle, and other accessories. In addition to its high-precision spindle and contouring capability, VF2 is designed for maximum rigidity. It has a robust mechanical structure with a cast iron body, six-sided rectangular column, and a robust cast iron table. HAAS VF-2 also uses the latest in modern electronics with an onboard Allen Bradley MiniLogix 1050 controller and a HAAS integrated PC for data input and output. HAAS VF2 is an excellent choice for CNC machining solutions. It is ideally suited for situations requiring tight tolerances and high accuracy. Additionally, it requires minimal maintenance and offers high performance at a competitive price.

There are no reviews yet