Used HAAS VF-2SS #9280676 for sale

URL successfully copied!

Tap to zoom

ID: 9280676

Vintage: 2006

CNC Vertical machining center

4 Axis

Table size: 36" x 14"

Max. table load: 1500 lbs

Travel:

X-Axis: 30"

Y-Axis: 16"

Z-Axis: 20"

Spindle speed: 12,000 RPM

Spindle taper: CT40

Spindle motor: 30 HP

Tool changer: 24

Max. tool diameter: 3"

Max. feedrate: 1,400 IPM

Max. cutting rate: 833 IPM

Equipped with:

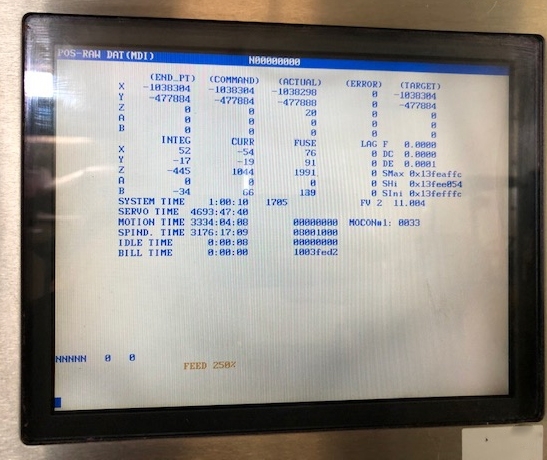

HAAS CNC Control

Rigid tapping

Programmable coolant nozzle

Visual quick code programming

Floppy drive, 3.5"

Spindle orientation

Remote jog handle

User definable macros

High speed machining

Macros

Ethernet

Coolant tank and pump

4th-Axis Pre-wired

Auger chip conveyor

2006 vintage.

HAAS VF-2SS is a high-performance vertical machining center designed for use in a variety of industrial applications. It features a highly rigid spindle head assembly, optimally designed rigid table, and a large working envelope. The result is maximum component accuracy, speed, and efficiency. VF-2SS is driven by a powerful 20 hp vector drive motor with direct-drive technology. This, along with 4th axis options, enables the operator to maximize the machine's speed and production potential. The machine also features an impressive vector drive feedrate of 3300 inches per minute, with a total cutting feedrate of 13,500 inches per minute. The spacious work area in HAAS VF-2SS measures 40" x 20" x 25" and utilizes a 30-station automatic tool changer (ATC) to allow for quick tool changes with minimal downtime. The ATC is driven by a high-torque servo motor that quickly and accurately moves the tool holders in and out of the spindle. The spindle on VF-2SS spins at 7,500 RPM, and can handle a variety of tooling and cutting strategies. A dual-arm tool presetter is also included to speed up setup and allow accurate tool measuring, as well as for troubleshooting any problems. HAAS VF-2SS features advanced technologies that provide the operator with the best possible machining experience. Its rigid construction and direct-drive vector motor both work together to maximize speed and accuracy while minimizing chatter marks and thermal distortion. This helps achieve the best possible part quality while increasing yield, throughput, and profits. VF-2SS is perfect for those in need of a reliable machine tool capable of producing high-precision parts while operating at maximum efficiency.

There are no reviews yet